Power installation tightening device

A wire-tightening and electric power technology is applied in the field of electric installation and wire-tightening devices, which can solve the problems of danger, high labor intensity, and bulky device, and achieve the effect of preventing tilting and dumping and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

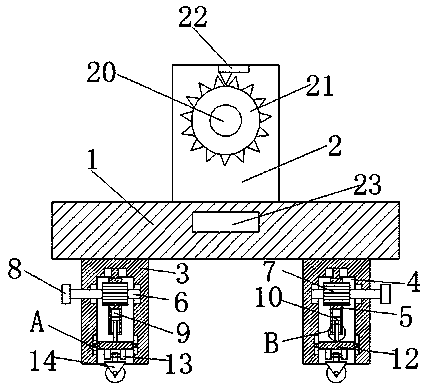

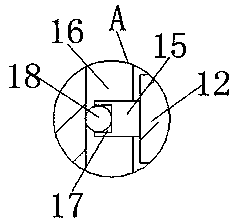

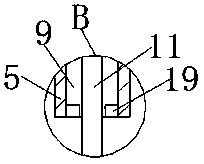

[0020] refer to Figure 1-3 , an electric installation tightening device, including a base 1, the upper end of the base 1 is connected with a fixed base 2, the fixed base 2 is connected with a rotating drum 20 through the rotation of the first bearing, and the four corners of the lower end of the base 1 are connected with sleeve columns 3 , the lower end of the sleeve column 3 is provided with a moving groove 4, the bottom of the moving groove 4 is fixedly and rotatably connected with a worm 5 through the second bearing, and the corresponding groove wall of the moving groove 4 is fixedly and rotatably connected with a rotating shaft 6 through the third bearing. The shaft 6 is sleeved with a worm wheel 7 meshing with the worm 5, one end of the rotating shaft 6 passes through the corresponding second bearing and the sleeve 3 in turn and extends outward to connect with a rotating disc 8, and the lower end of the worm 5 is provided with a thread groove 9 , the thread groove 9 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com