A sewage separation and environmental protection treatment device

An environmental protection and sewage treatment technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve problems such as manual cleaning, easy to block grids, and affect sewage treatment efficiency, and achieve The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

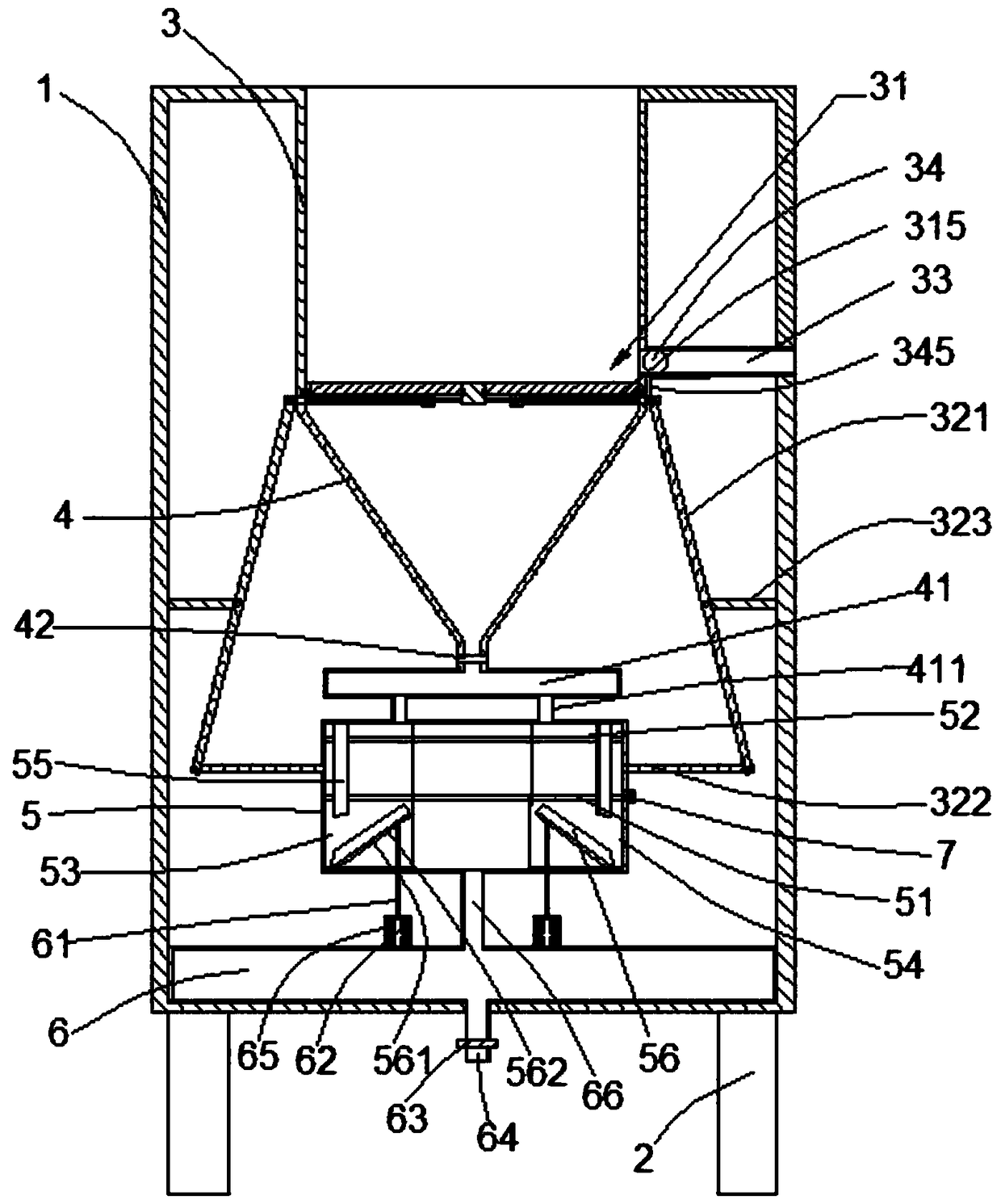

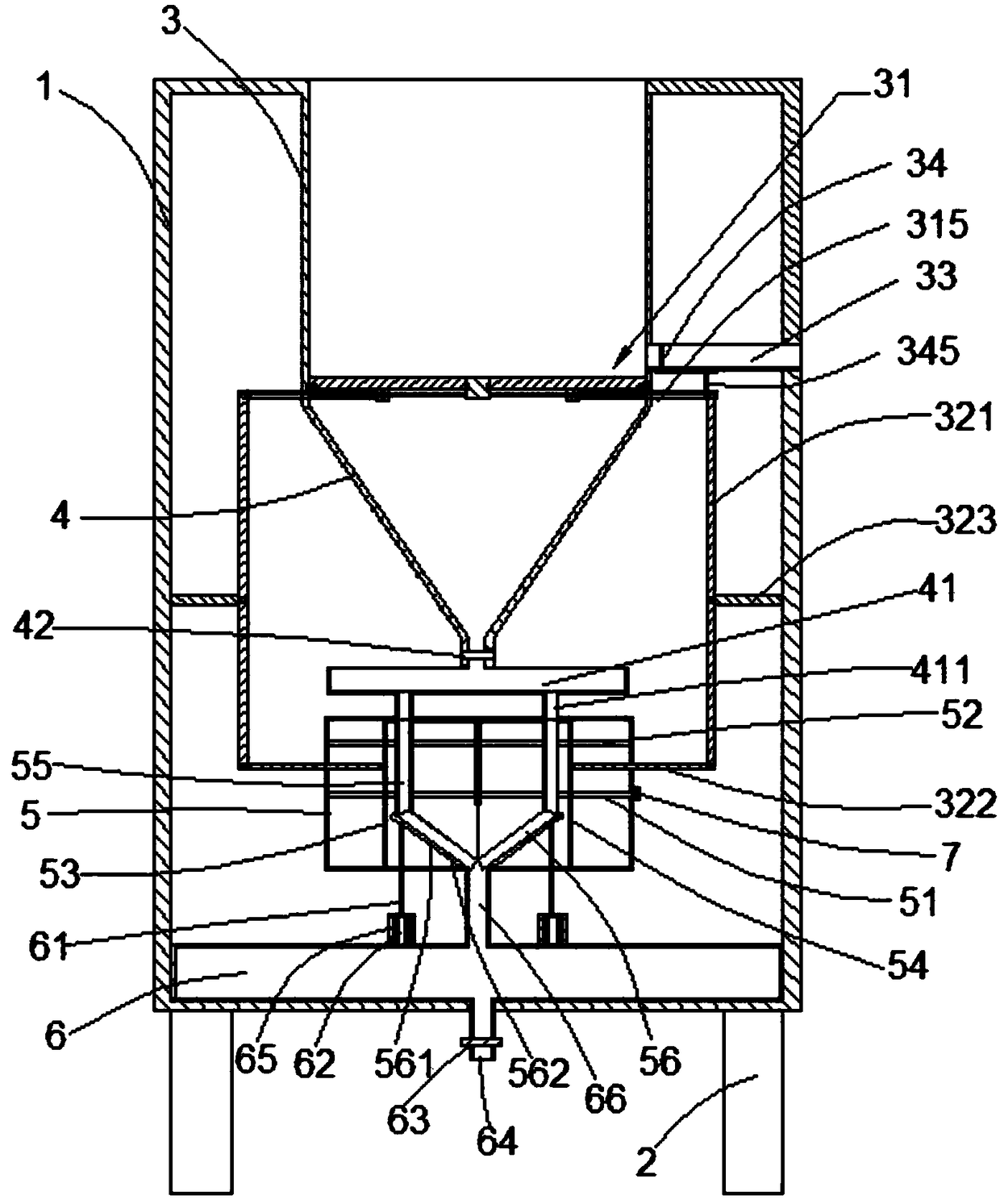

[0025] This embodiment provides a sewage separation and environmental protection treatment device, which includes a frame 1 and supporting legs 2 at the bottom thereof. The inside of the frame 1 is provided with a water storage chamber 3, a conical sedimentation tank 4, and a sliding chamber from top to bottom. 5 and the sedimentation chamber 6, the bottom end of the side wall of the water storage chamber 3 is provided with a clean water outlet 33 and the bottom of the water storage chamber 3 and the top of the conical sedimentation tank 4 are isolated by a folded isolation plate 31, and the folded isolation plate 31 includes Several fan-shaped folded sheets 311 stretch along the first circular slide rail 312 and the second circular slide rail 313, and the bottom of the conical sedimentation tank 4 communicates with the slide chamber 5 through the transfer pipes 411 at both ends of the transfer chamber 41 , the sliding cavity 5 is provided with a screw rod 51 and a sliding rod ...

Embodiment 2

[0027] Such as Figure 1-6As shown, the present embodiment provides a sewage separation and environmental protection treatment device, including a frame 1 and supporting legs 2 at the bottom thereof. The inside of the frame 1 is provided with a water storage chamber 3, a conical sedimentation tank 4, Sliding chamber 5 and sedimentation chamber 6, the bottom end of the side wall of the water storage chamber 3 is provided with a clean water outlet 33 and the bottom of the water storage chamber 3 and the top of the conical sedimentation tank 4 are isolated by a folded isolation plate 31, the folded isolation The plate 31 includes several fan-shaped folded sheets 311 that expand and contract along the first circular slide rail 312 and the second circular slide rail 313. 5 conducting, the sliding cavity 5 is provided with a screw rod 51 and a sliding rod 52 extending left and right through the left sliding block 53 and the right sliding block 54, and the screw rod 51 is respectivel...

Embodiment 3

[0029] Such as Figure 1-6 As shown, the present embodiment provides a sewage separation and environmental protection treatment device, including a frame 1 and supporting legs 2 at the bottom thereof. The inside of the frame 1 is provided with a water storage chamber 3, a conical sedimentation tank 4, Sliding chamber 5 and sedimentation chamber 6, the bottom end of the side wall of the water storage chamber 3 is provided with a clean water outlet 33 and the bottom of the water storage chamber 3 and the top of the conical sedimentation tank 4 are isolated by a folded isolation plate 31, the folded isolation The plate 31 includes several fan-shaped folded sheets 311 that expand and contract along the first circular slide rail 312 and the second circular slide rail 313. 5 conducting, the sliding cavity 5 is provided with a screw rod 51 and a sliding rod 52 extending left and right through the left sliding block 53 and the right sliding block 54, and the screw rod 51 is respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com