Garbage compression module

A technology of garbage compression and components, which is applied in the direction of garbage cans, garbage collection, presses, etc., can solve the problems of garbage scattering, dumping of garbage cans with push rods, etc., and achieve the effect of reducing the emission of peculiar smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment discloses a garbage compression component, and the whole and / or part of the content of the preferred implementations of other embodiments may be used as a supplement to this embodiment under the condition that no conflict or contradiction is caused.

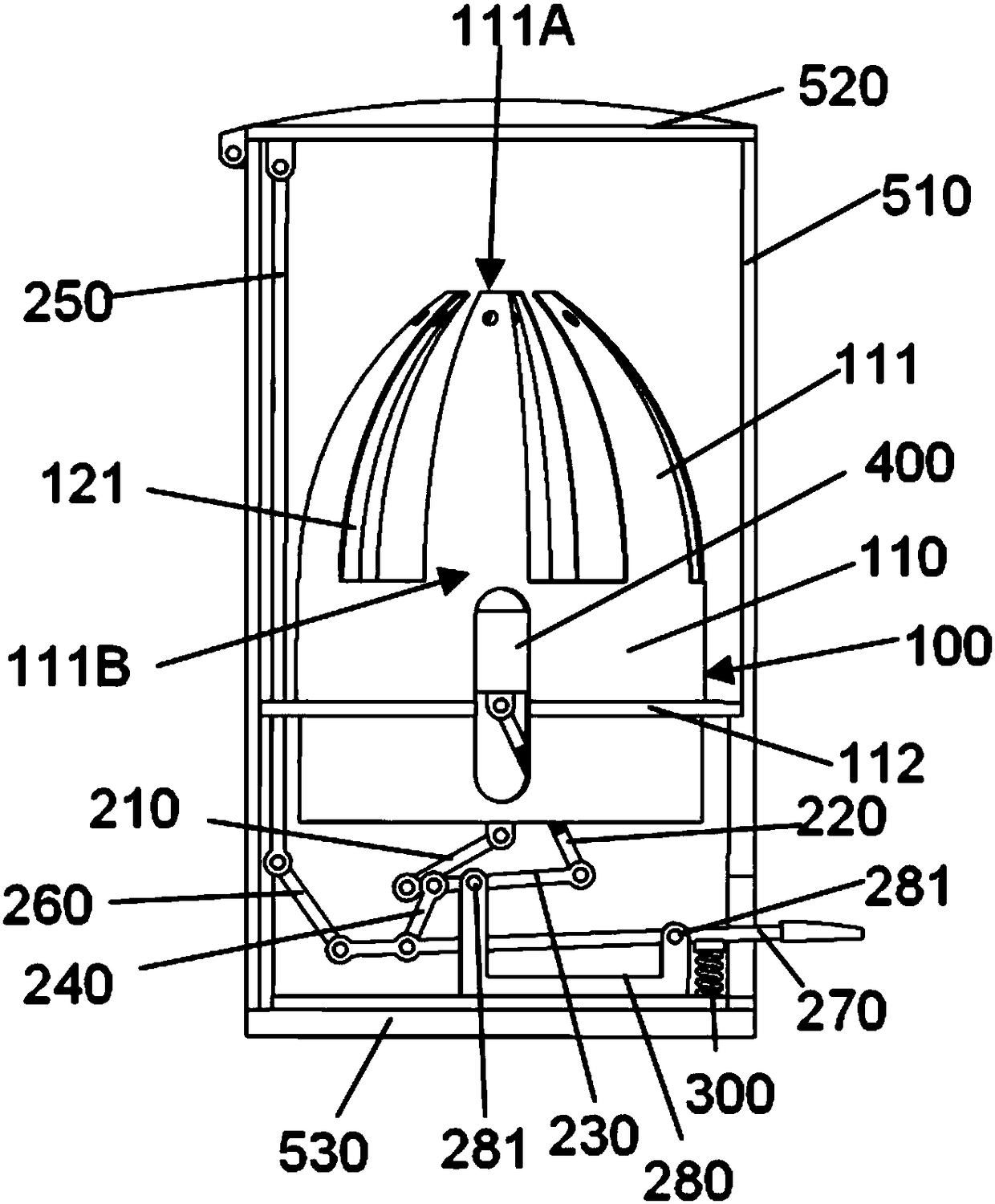

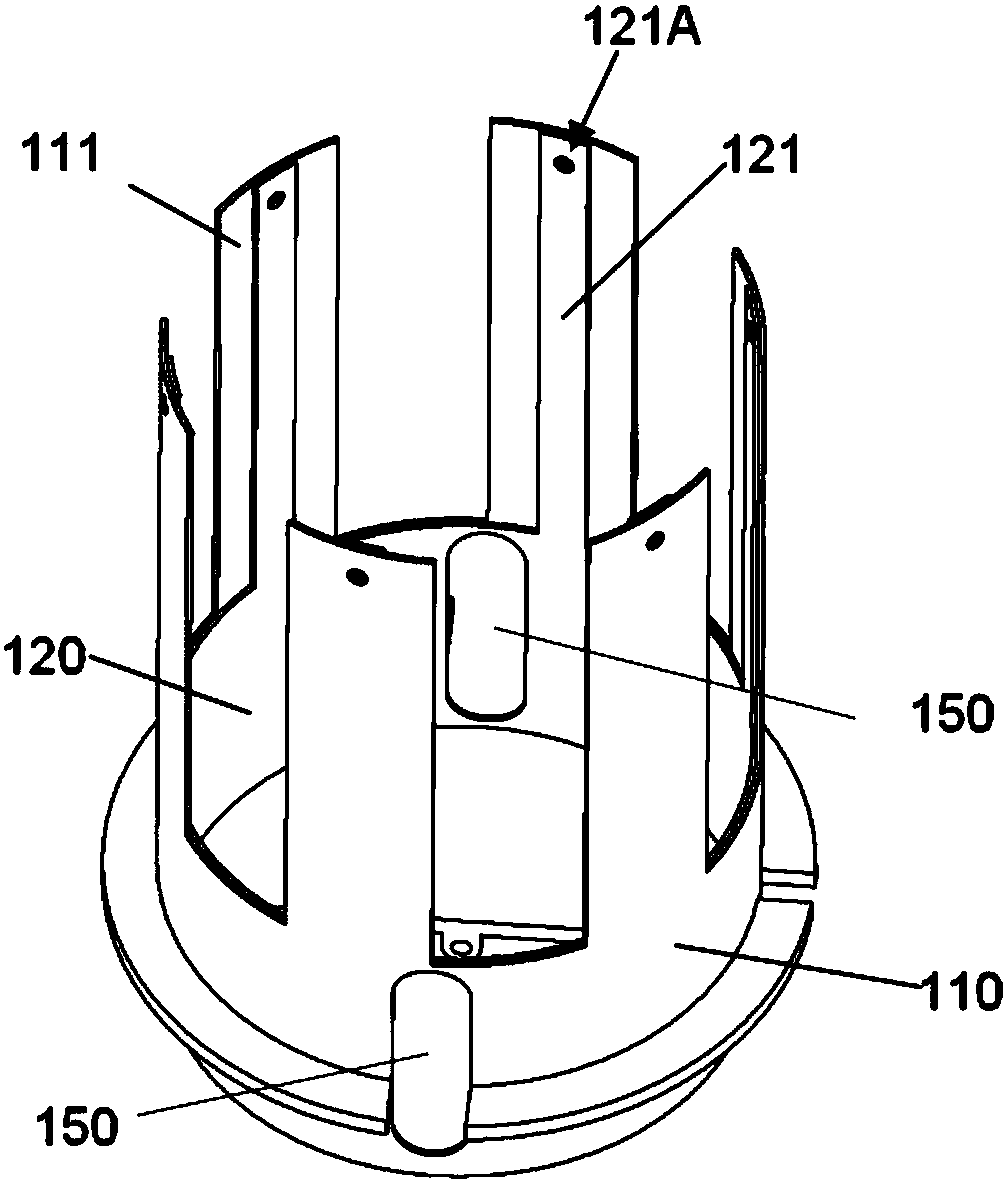

[0050] According to a preferred embodiment, a garbage compression assembly may include a first inner barrel 110 . The garbage compression assembly may further include a second inner barrel 120 that can slide relative to the first inner barrel 110 . Preferably, the first inner tub 110 and the second inner tub 120 are nested and connected to the common opening only at the top in such a way that the common opening can be shrunk when sliding relative to each other, and thus can produce the effect of compressing garbage when the common opening is closed force. Preferably, the second inner barrel 120 is nested in the first inner barrel 110, and is fixed only at the common opening. Preferably, at least a partial...

Embodiment 2

[0060]This embodiment may be a further improvement and / or supplement to Embodiment 1, and repeated content will not be repeated here. In the case of no conflict or contradiction, the whole and / or part of the content of the preferred implementations of other embodiments may serve as supplements to this embodiment.

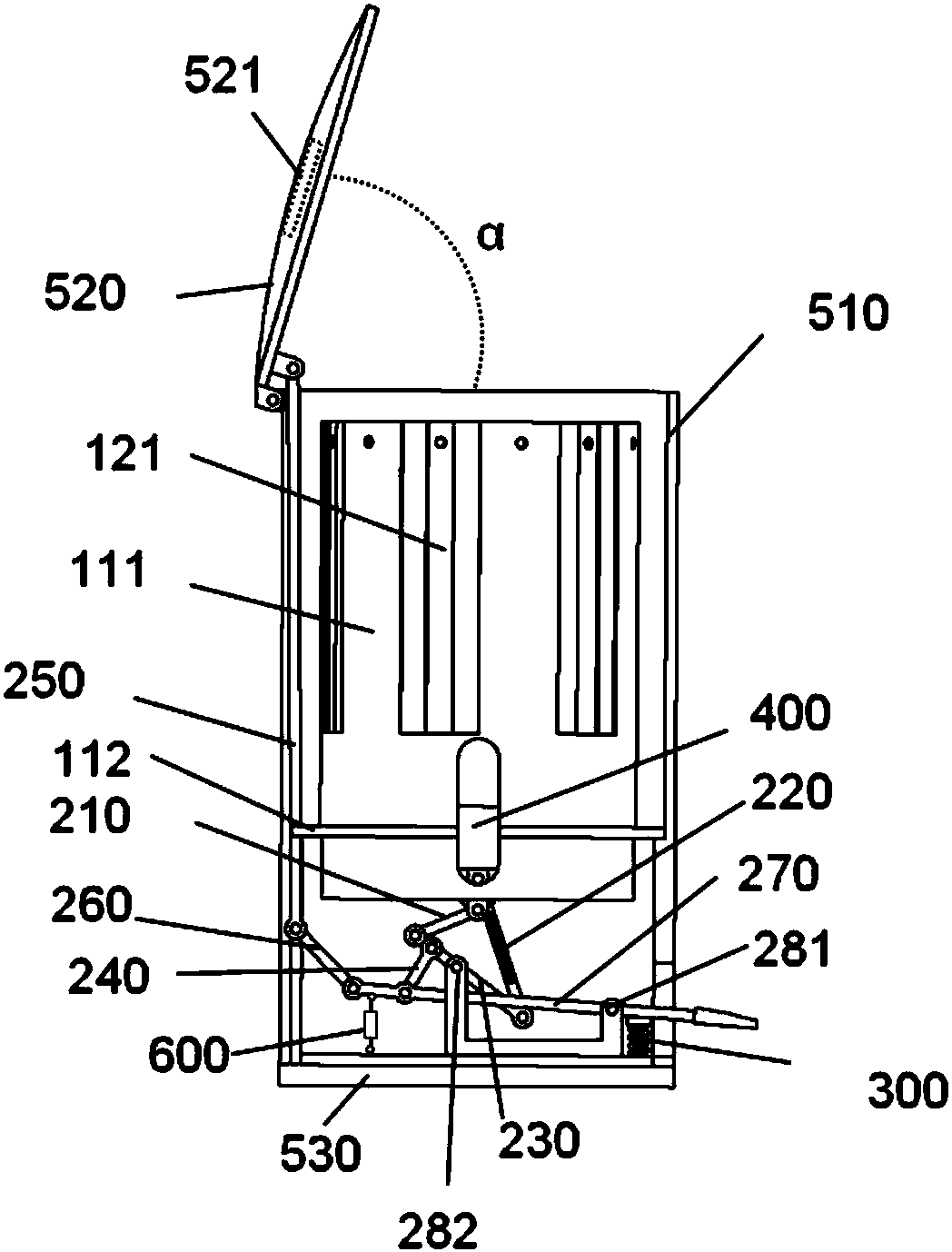

[0061] According to a preferred embodiment, a garbage compression assembly may include a first inner bucket 110 and a second inner bucket 120 that can slide vertically along the first inner bucket 110 . Preferably, the first inner barrel 110 and the second inner barrel 120 are nested and connected to the common opening only at the top in such a way that the common opening can be contracted, and thus can generate an elastic force for compressing garbage when the common opening is closed. Preferably, the bottom end of the second inner tub 120 opposite to the common opening bears the compressive force exerted by the connecting rod assembly which can also be used to ope...

Embodiment 3

[0063] This embodiment may be a further improvement and / or supplement to Embodiment 1, 2 or their combination, and repeated content will not be repeated. In the case of no conflict or contradiction, the whole and / or part of the content of the preferred implementations of other embodiments may serve as supplements to this embodiment.

[0064] According to a preferred embodiment, see figure 1 , 2 and 3, the garbage compression assembly may include an inner tub 100 , a pedal lever 270 and a return spring 300 . The return spring 300 can be used to rotate the pedal lever 270 back to its original position through elastic force when the pedal lever 270 is not subject to artificial force. The inner tub 100 may include a first inner tub 110 and a second inner tub 120 disposed inside the first inner tub 110 . At least two first elastic pieces 111 may be provided on the upper part of the first inner tub 110 . At least two second elastic sheets 121 may be provided on the upper part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com