Double-layer tea caddy

A tea can, double-layer technology, applied in the field of double-layer tea cans, can solve the problems of easy oxidation of tea, high vacuum degree in the can, poor heat insulation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

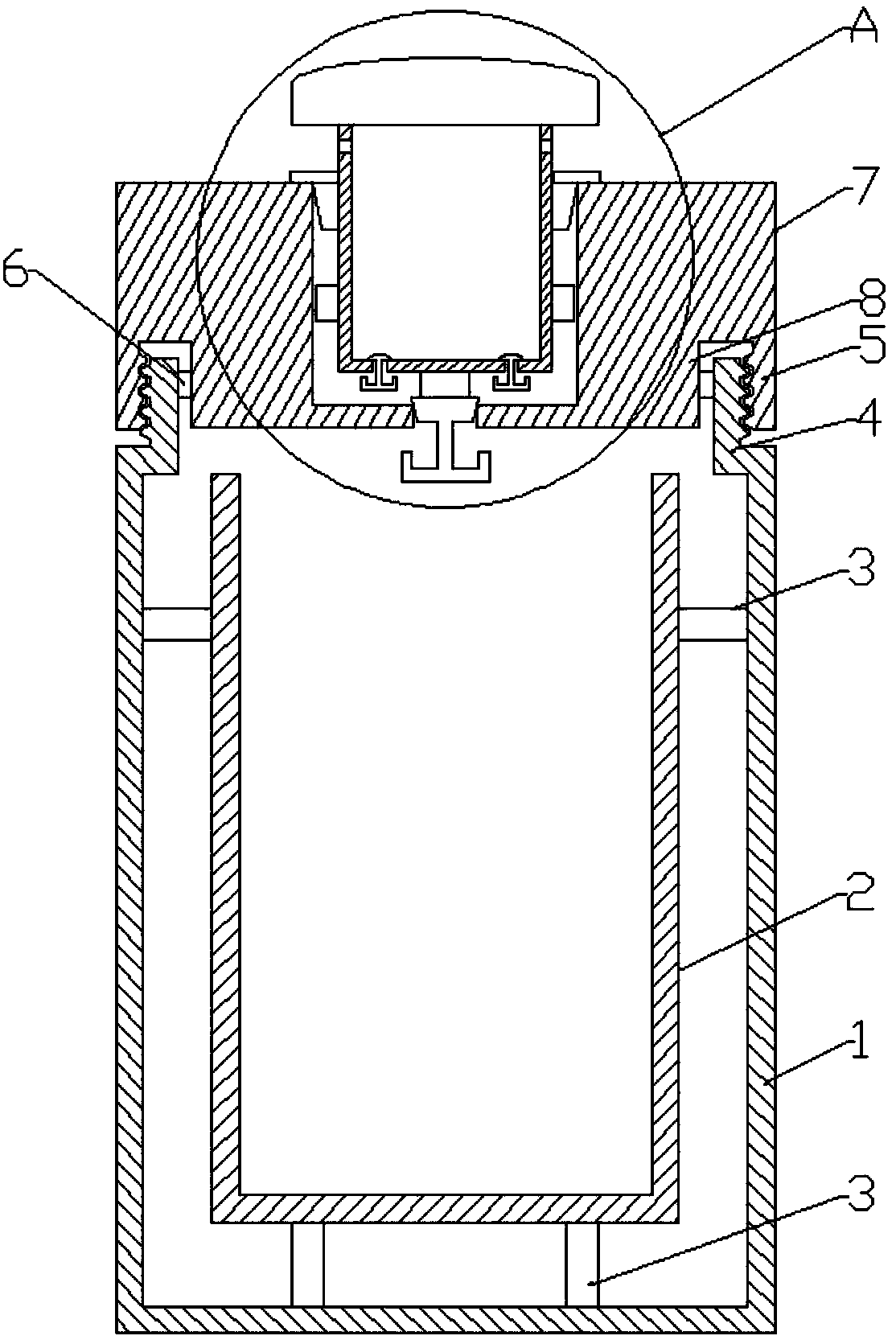

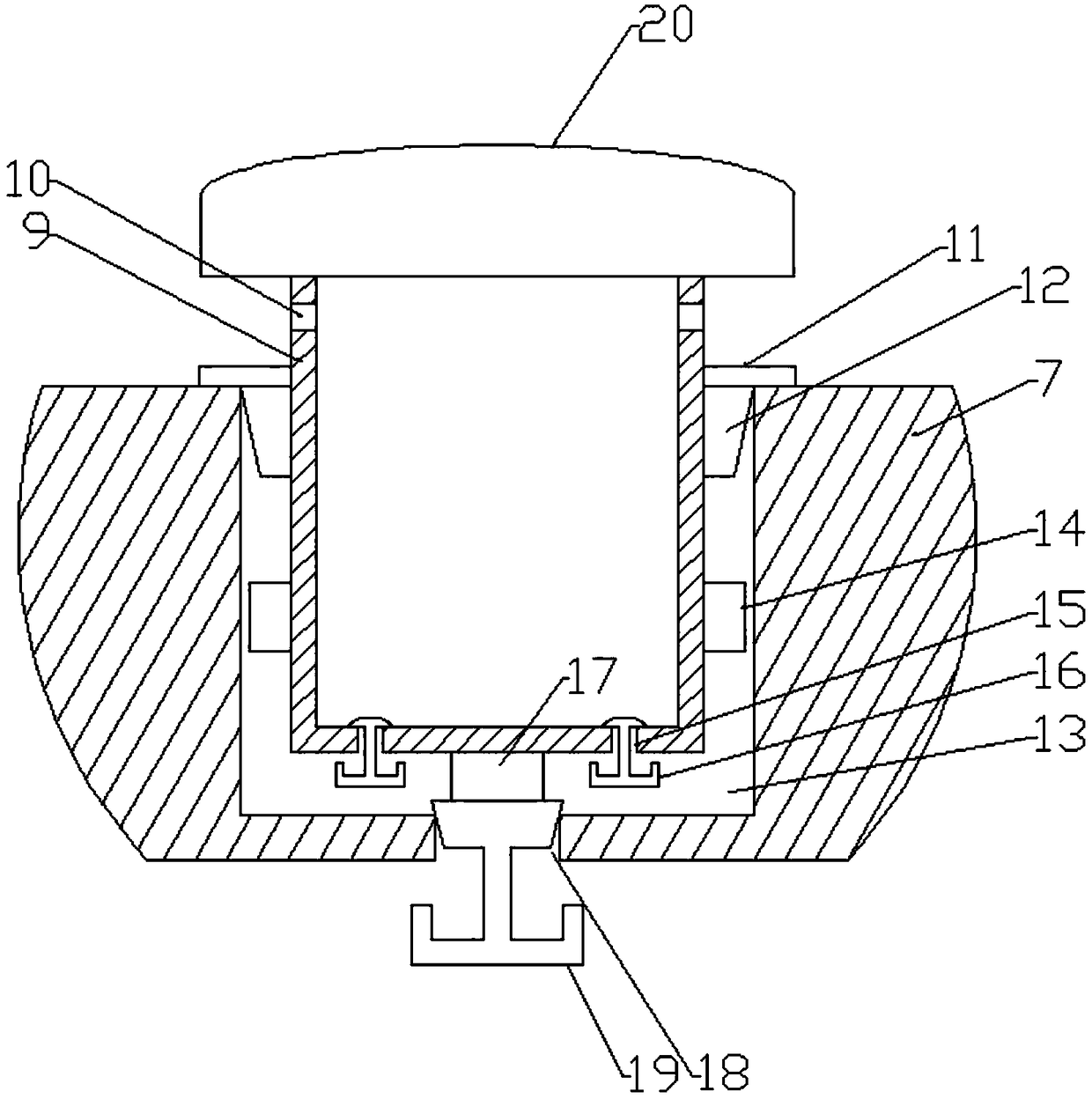

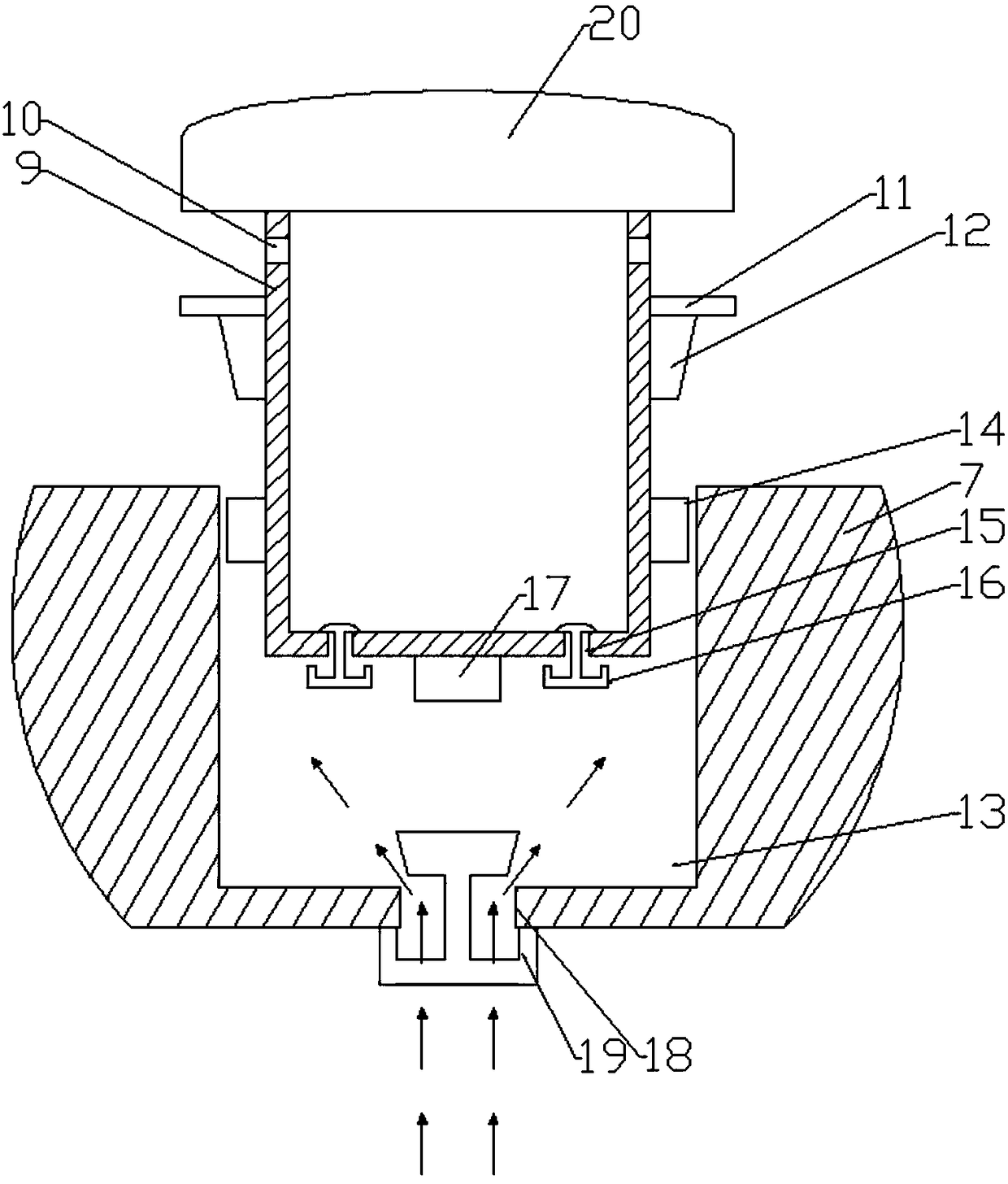

[0016] Figure 1-6 A specific embodiment of the present invention is shown: a double-layered tea pot, comprising an outer pot body 1 and an inner pot body 2, the bottom and side walls of the outer pot body 1 are provided with struts 3, and the inner pot body 2 is fixed On the support rod 3, the upper end of the outer tank body 1 is provided with a tank inner wall 4, and the tank inner wall 4 is provided with a tank cover 7. The tank cover 7 includes the cover outer wall 5 and the cover inner wall 88, so The outer wall 5 of the cover is threadedly connected with the inner wall 4 of the tank, the inner wall 88 of the cover is provided with a sealing ring 6, the inner wall 88 of the cover is in contact with the inner side of the inner wall 4 of the tank, and the middle of the lid 7 is provided with a pump. The air cavity 13, the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com