Automatic hot-glue carton sealing machine

A technology of hot melt adhesive and carton sealing machine, which is used in packaging sealing/fastening, external support, transportation packaging, etc., can solve the problems of unstable gluing, low sealing efficiency, low positioning accuracy, etc., to reduce packing Time required, smooth and fast movement, and the effect of improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

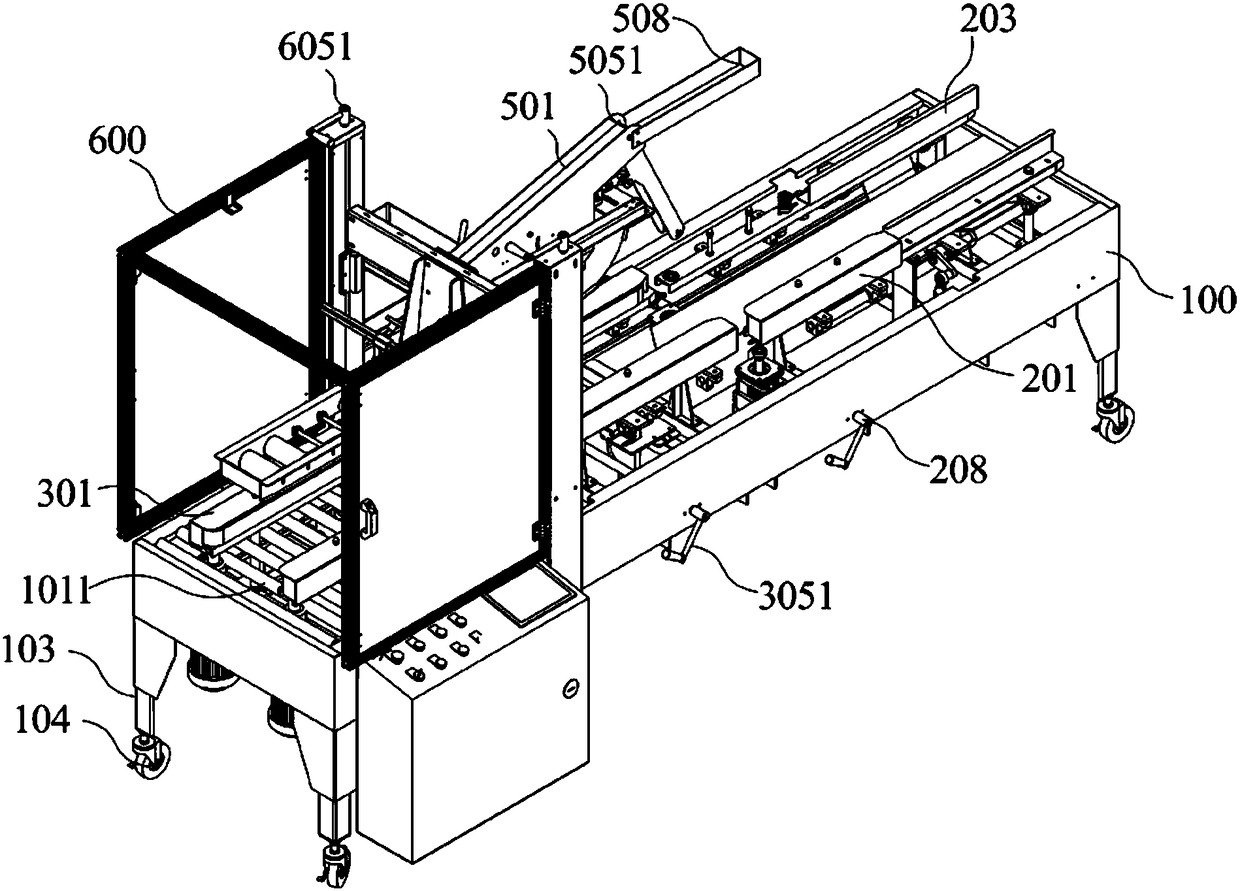

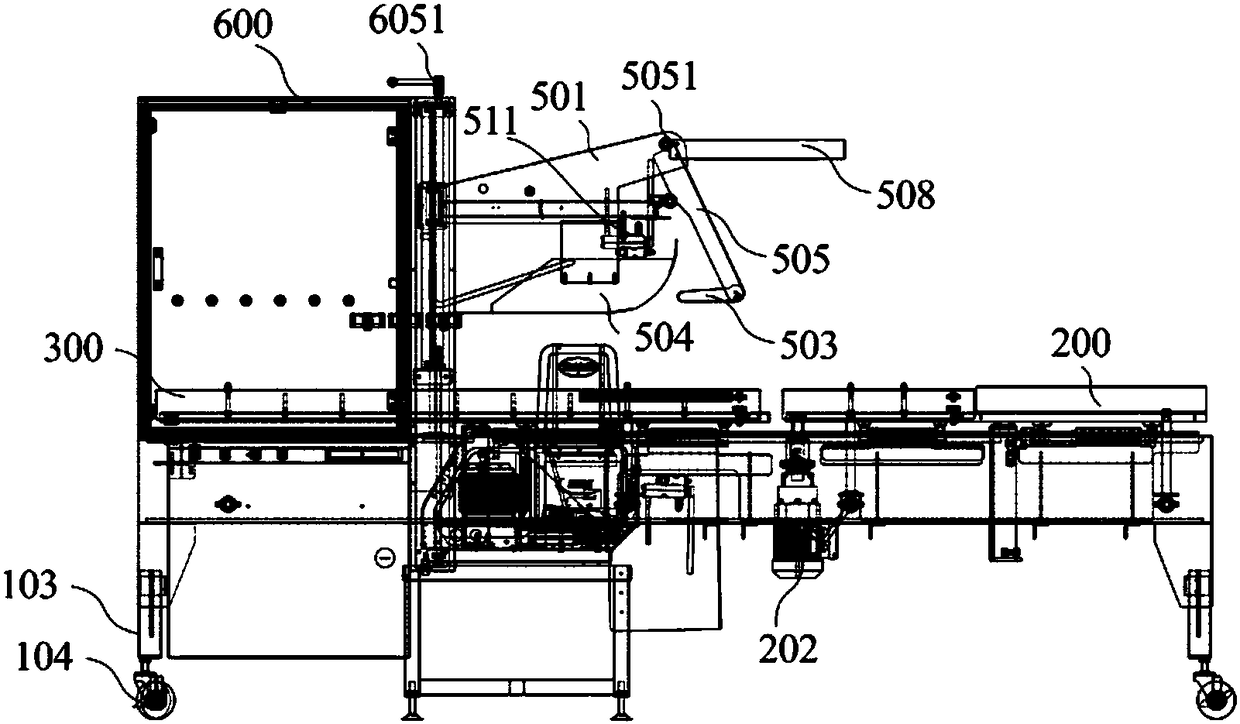

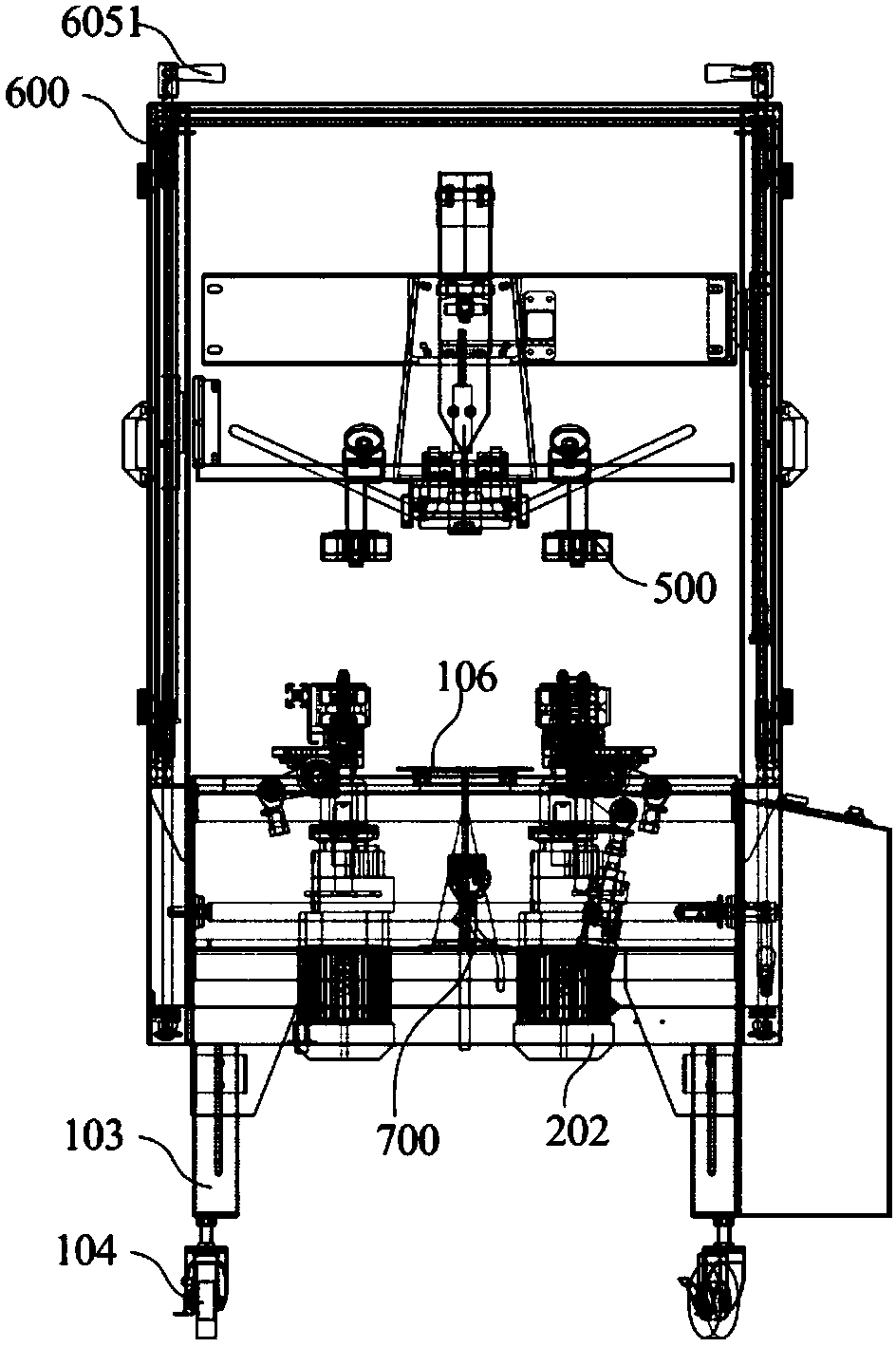

[0075] In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art; the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously; the accompanying drawings in the following description are only embodiments of the present invention; for those of ordinary skill in the art; on the premise of not paying creative work; other accompanying drawings can also be obtained according to these accompanying drawings; and other implementation.

[0076] In order to make the drawing concise; each drawing only schematically shows the parts related to the present invention; but it does not represent its actual structure as a product.

[0077] The present invention mainly aims at encapsulating the upper and lower covers of the carton. There are open covers on the four sides of the top opening of the carton. The open front cover is the end of the carton that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com