Air cooling device for automobile hat and coat stand fiberglass board production line

A technology of an air cooling device and a coat rack, which is applied in the field of auto parts production, can solve the problem that the air deflector is not easy to maintain, and achieve the effects of simple structure, sensitive operation and good cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

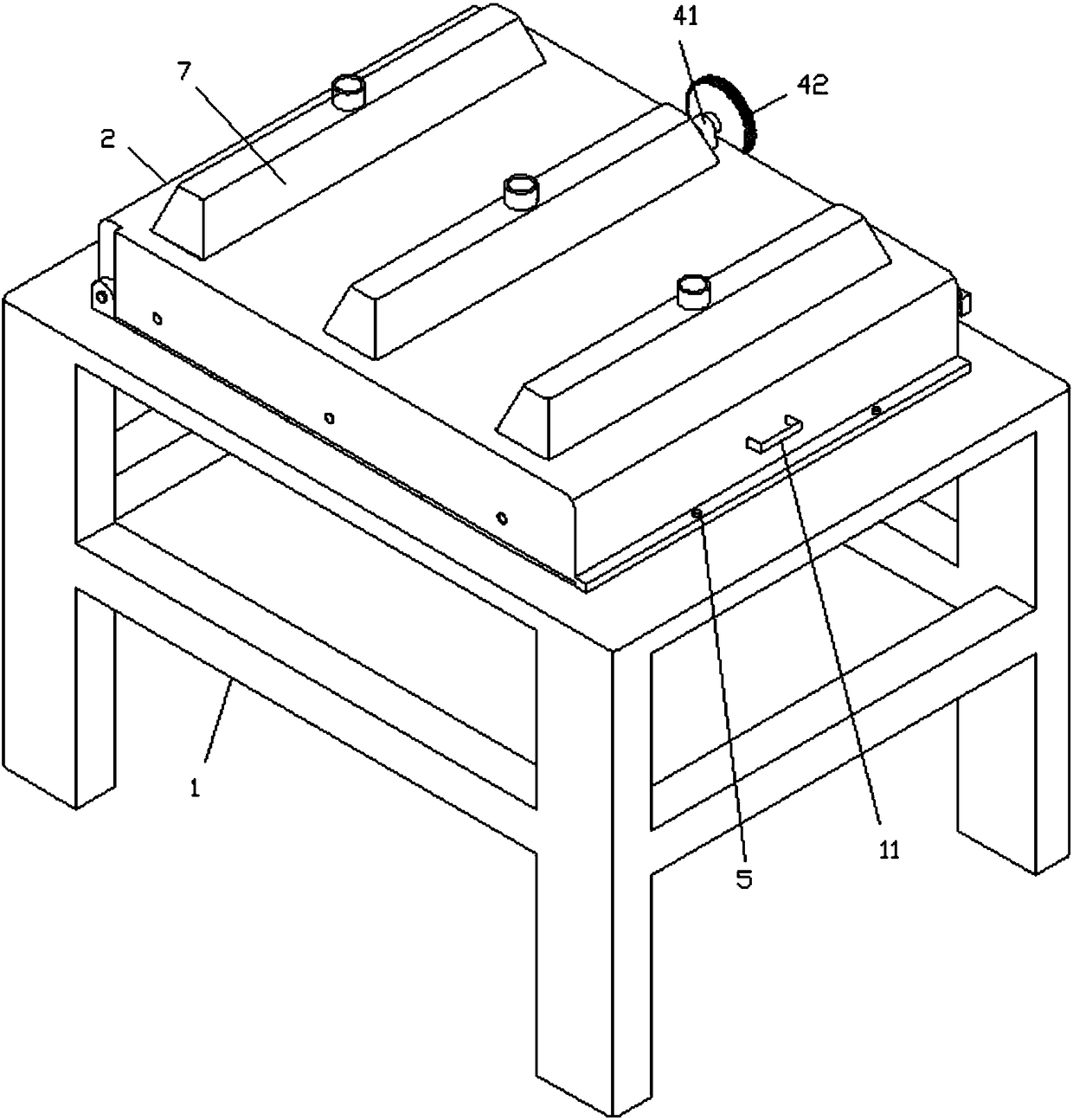

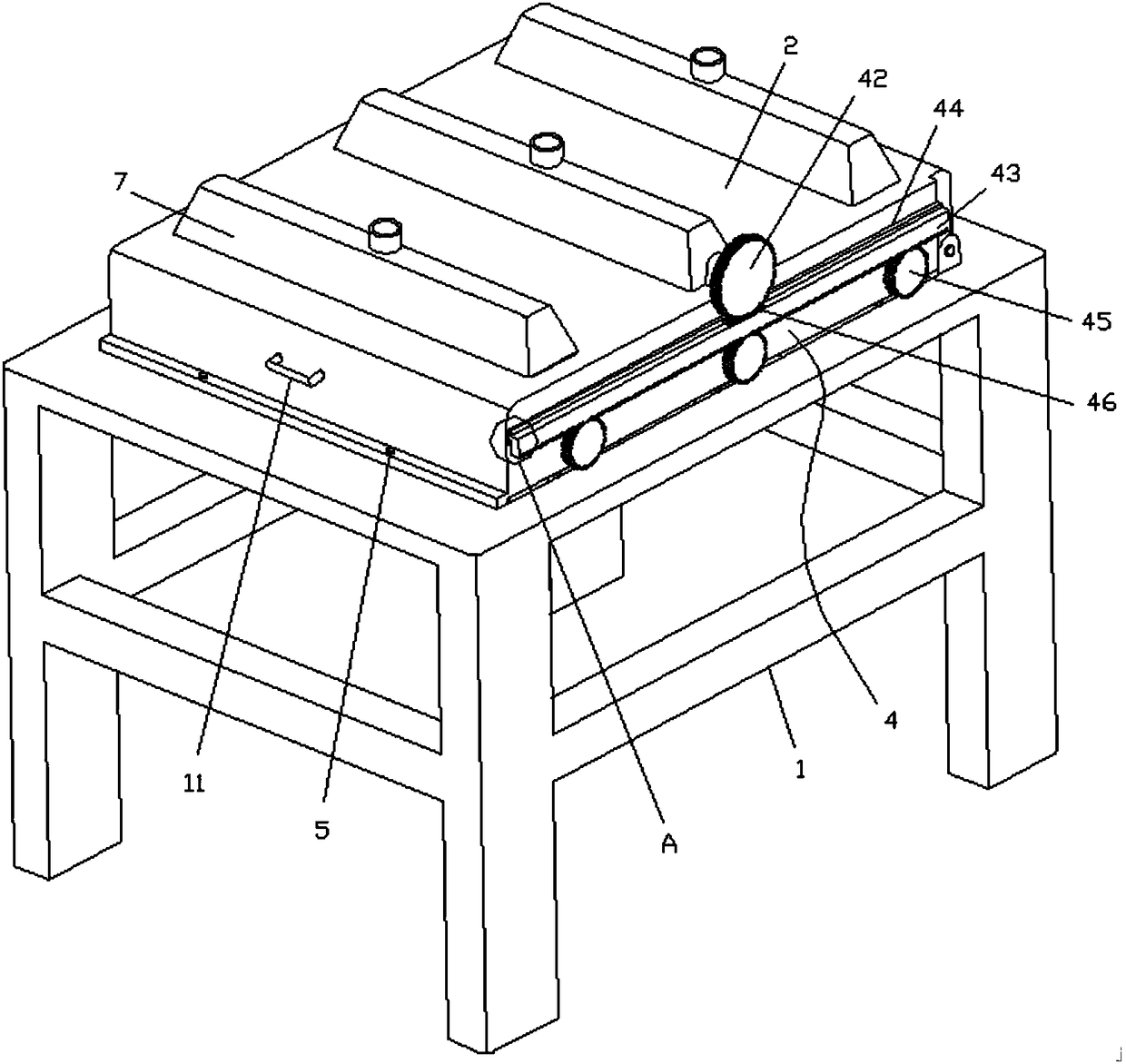

[0023] Such as Figure 1 to Figure 5 Shown, a kind of air-cooling device for the production line of glass fiberboard of automobile coat rack, comprises air-cooling frame 1, air-cooling chamber 2, wind deflector 3 and changing assembly 4, and one end of described air-cooling chamber 2 is hinged on One side of the air-cooled frame 1, the other end is connected with the air-cooled frame 1 by bolts 5, and the bottom of the air-cooled chamber 2 is provided with several air outlets 6, and the air outlet 6 is rotatably connected with the The wind deflector 3, the wind deflector 3 is connected to both sides of the air-cooled chamber 2 through the rotating shaft, and the top of the air-cooled chamber 2 is provided with an air inlet 54;

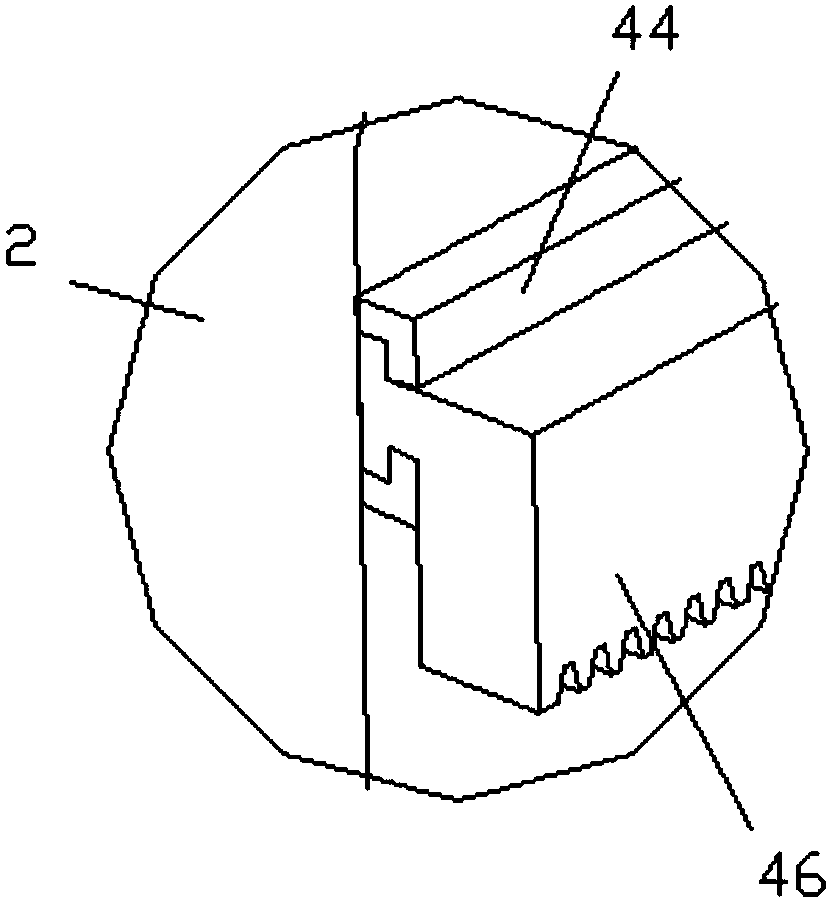

[0024] The direction changing assembly 4 includes a servo motor 41, a driving gear 42, a rack 43, a chute 44 and a driven gear 45. The servo motor 41 is installed on the side of the air cooling chamber 2, and the rack 43 is slidably connected to the ai...

Embodiment 2

[0029] Such as Figure 1 to Figure 4 Shown, a kind of air-cooling device for the production line of glass fiberboard of automobile coat rack, comprises air-cooling frame 1, air-cooling chamber 2, wind deflector 3 and changing assembly 4, and one end of described air-cooling chamber 2 is hinged on One side of the air-cooled frame 1, the other end is connected with the air-cooled frame 1 by bolts 5, and the bottom of the air-cooled chamber 2 is provided with several air outlets 6, and the air outlet 6 is rotatably connected with the The wind deflector 3, the wind deflector 3 is connected to both sides of the air-cooled chamber 2 through the rotating shaft, and the top of the air-cooled chamber 2 is provided with an air inlet 54;

[0030] The direction changing assembly 4 includes a servo motor 41, a driving gear 42, a rack 43, a chute 44 and a driven gear 45. The servo motor 41 is installed on the side of the air cooling chamber 2, and the rack 43 is slidably connected to the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com