Method for designing performance parameters of wheel encasing type automobile carrier

A technology for car carrier and parameter design, which is applied in the field of mechanical engineering and can solve problems such as the inability to establish an accurate relationship between system parameters and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

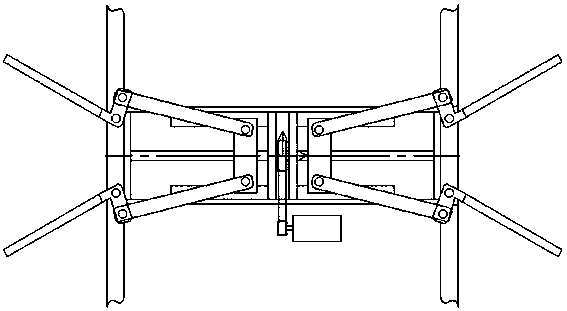

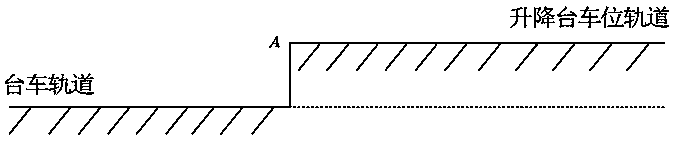

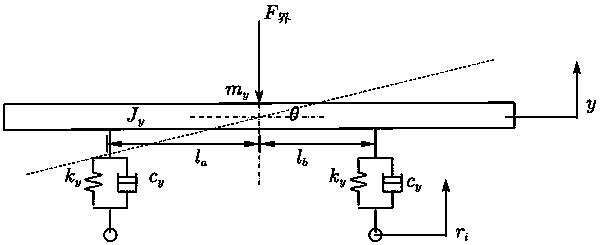

Image

Examples

Embodiment

[0146] The initial design parameters of the system for a carrier are shown in Table 1:

[0147] Table 1

[0148]

[0149] The mass, stiffness, and damping matrices brought into the dynamic model of the carrier system are obtained as follows:

[0150]

[0151]

[0152]

[0153] Run the Newmark numerical integral calculation program to obtain the dynamic load coefficient of the load on the arm of the carrier as follows: Figure 7

[0154] In step 3, a certain RBF proxy model is as follows: Figure 8 , where the genetic algorithm solution parameters are listed in Table 2 below:

[0155] Table 2

[0156]

[0157] get the optimized solution as Figure 9 .

[0158] Through empirical data, it can be obtained that the value of α is 0.65, and the value of β is 0.35. Using this standard method to calculate the formula to obtain the comprehensive evaluation degree distribution of the optimal solution is as follows: Figure 10 .

[0159] when k i =k 5 =0.1510 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com