A multi-axis linkage winding machine for irregular pipe body wrapping

A multi-axis linkage and irregular technology, which is applied in the direction of rotating and wrapping articles, and can solve the problems of irregular tubular articles entanglement and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

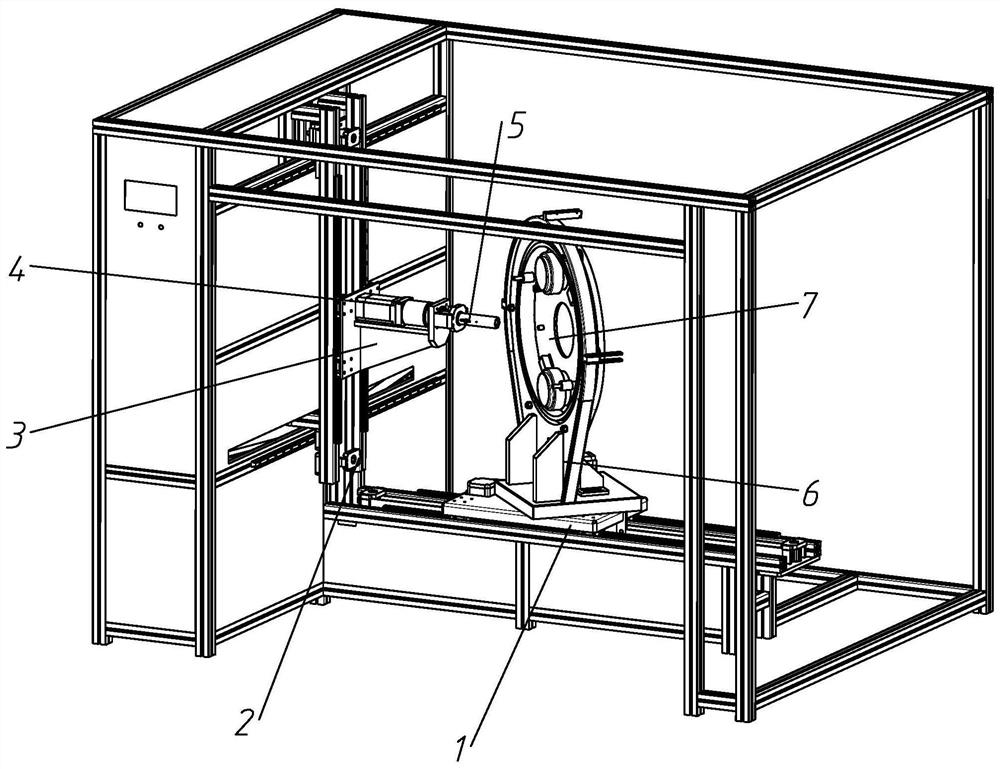

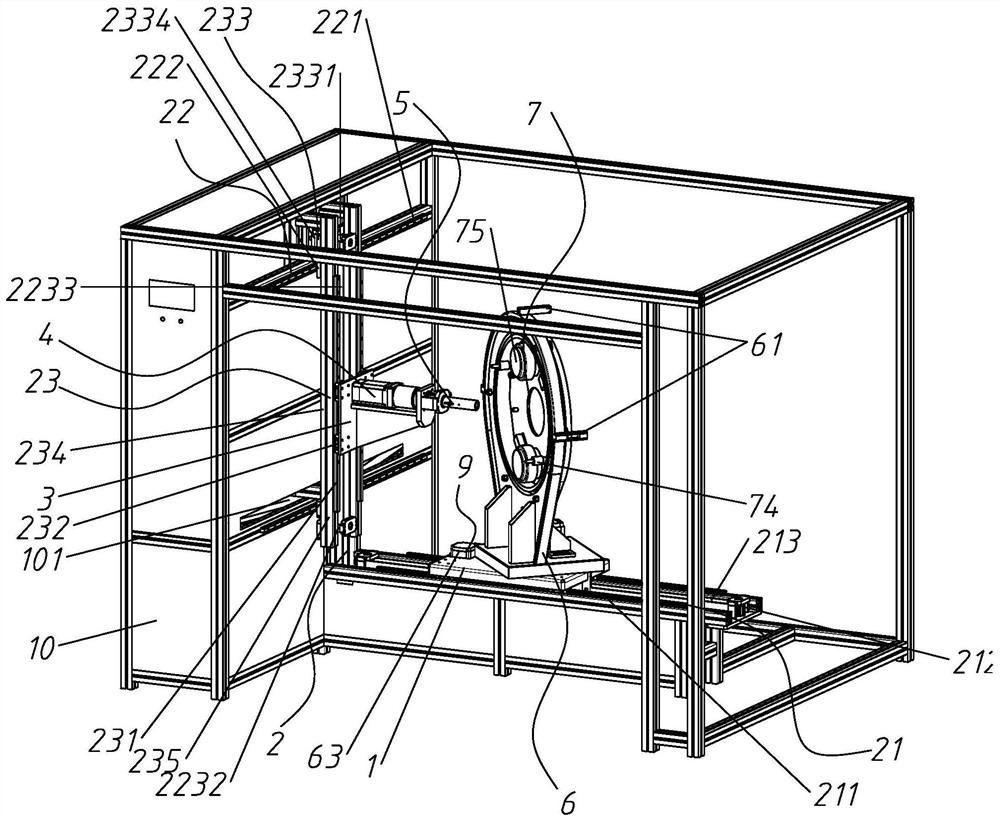

[0048] A multi-axis linkage winding machine for irregular pipe wrapping, including a base 1, the base 1 is connected with a clamping bracket 3 through a moving device 2, and the clamping bracket 3 is positioned relative to the base 1 through the moving device 2 Three-dimensional translational movement is performed, the clamping bracket 3 is provided with a clamping part 5 through the rotation of the rotation device 1 4, and the winding frame 6 is installed on the base 1 through the rotation of the rotation device 2 9, and the rotating shaft of the winding frame 6 is connected with the clamping bracket 3 The axis of rotation is vertical, and the winding frame 6 is provided with a winding disk 7 for rotation, and the winding disk 7 is provided with a supporting device 8 for supporting the winding tape roll.

[0049] When the present invention just starts to work, the clamping part 5 can pass through the winding disk 7, and at this time the clamping part 5 is perpendicular to the ...

Embodiment 2

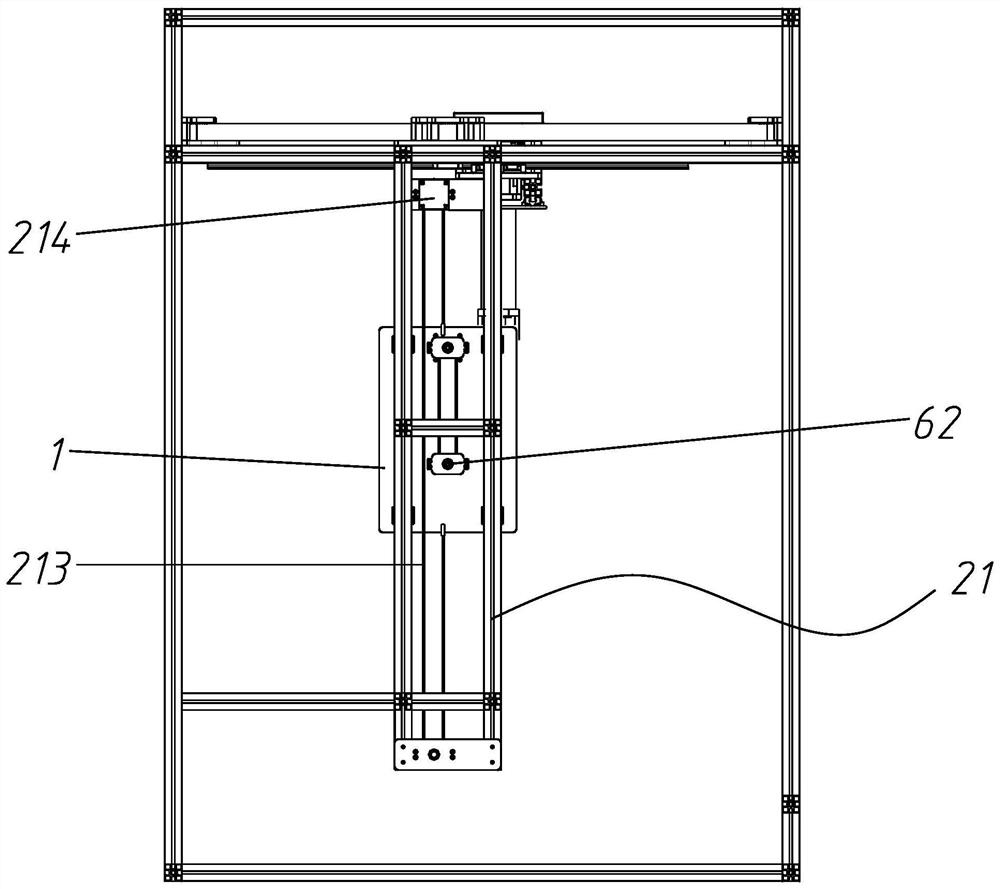

[0056] The moving device 2 includes an a-axis linear driving device 21 , a b-axis linear driving device 22 and a c-axis moving device 2 connected in sequence, the a-axis linear driving device 21 is connected to the base 1 , and the c-axis moving device 2 is connected to the clamping bracket 3 .

[0057] In this embodiment, the moving device 2 includes linear drive devices in three directions connected sequentially, thereby realizing the adjustment of the distance and relative position between the base 1 and the clamping bracket 3, wherein the a-axis, b-axis and c-axis are not collinear with each other. In the embodiment, the base 1 can be used as the origin, and a three-dimensional coordinate system can be established along the directions of the a-axis, b-axis and c-axis. By controlling the linear drive devices in the three directions, the position of the clamping bracket 3 in the coordinate system can be adjusted. Adjustment, the three-axis linear driving device satisfies the ...

Embodiment 3

[0059] The driving direction of the a-axis linear driving device 21 is parallel to the rotation axis of the clamping part 5 .

[0060] In this embodiment, when the a-axis linear drive device 21 directly connected to the base 1 is parallel to the rotation axis of the clamping part 5, when the winding machine winds a straight pipe, the a-axis linear drive device 21 can be driven as much as possible. It can drive the winding disc 7 to perform feeding motion, so that the present invention can also have a good application effect when winding some straight pipes, and improves the practicability of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com