Elastoplastic-damage finite-element algorithm of considering elastoplasticity and damage coupling of composite material

A composite material and elastoplastic technology, which is applied in the analysis of materials, the use of stable tension/pressure to test the strength of materials, calculations, etc., can solve problems such as shortage, unconsidered, and inability to describe the relationship between nonlinear damage and plastic interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

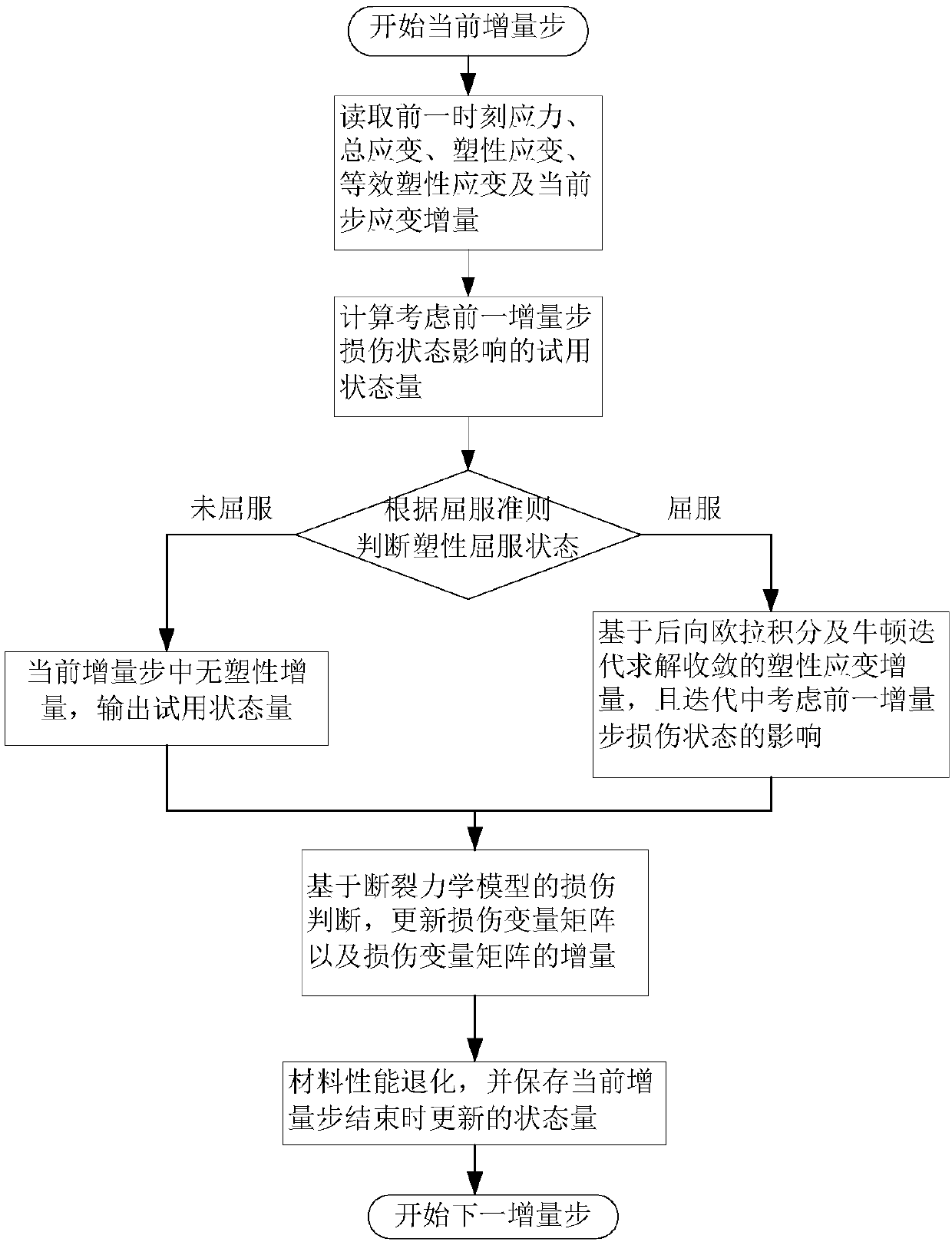

[0040] to combine figure 1 , an elastoplastic damage finite element subroutine algorithm considering the coupling effect of elastoplasticity and damage of fiber-reinforced resin matrix composites, including the following steps:

[0041] Step 1, start the current incremental step, read the convergence state quantity at the previous moment and the strain increment in the current incremental step; specifically:

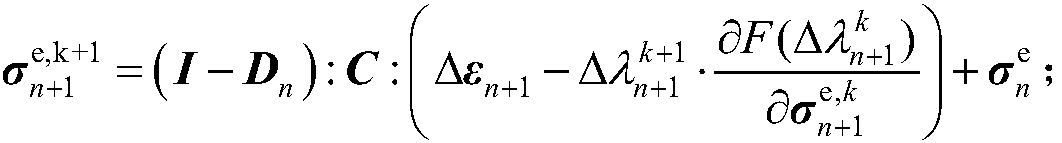

[0042] Read the previous incremental step ie tn The effective stress at the integration point of the material element at time Strain ε n , plastic strain Equivalent plastic strain value Damage state quantity D n And the current incremental step is the n+1th incremental step t n ~t n+1 time strain increment

[0043] effective stress strain plastic strain Damage state quantity D n for

[0044]

[0045] Among them, d 1 , d 2 are the damage variables representing fiber damage and matrix damage, respectively, d 12 , d 23 , d 13 is the damage variab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com