Upper-blowing type film blowing machine for high-pressure film

A film blowing machine and high-pressure film technology, which is applied in the field of blown film blowing machine, can solve the problems of unfavorable film cooling film blowing, inconvenient installation of mechanical equipment, small space for pulling out film bubbles, etc., and achieve mechanical structure design Ingenious, improve the surface texture and gloss of the bag body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

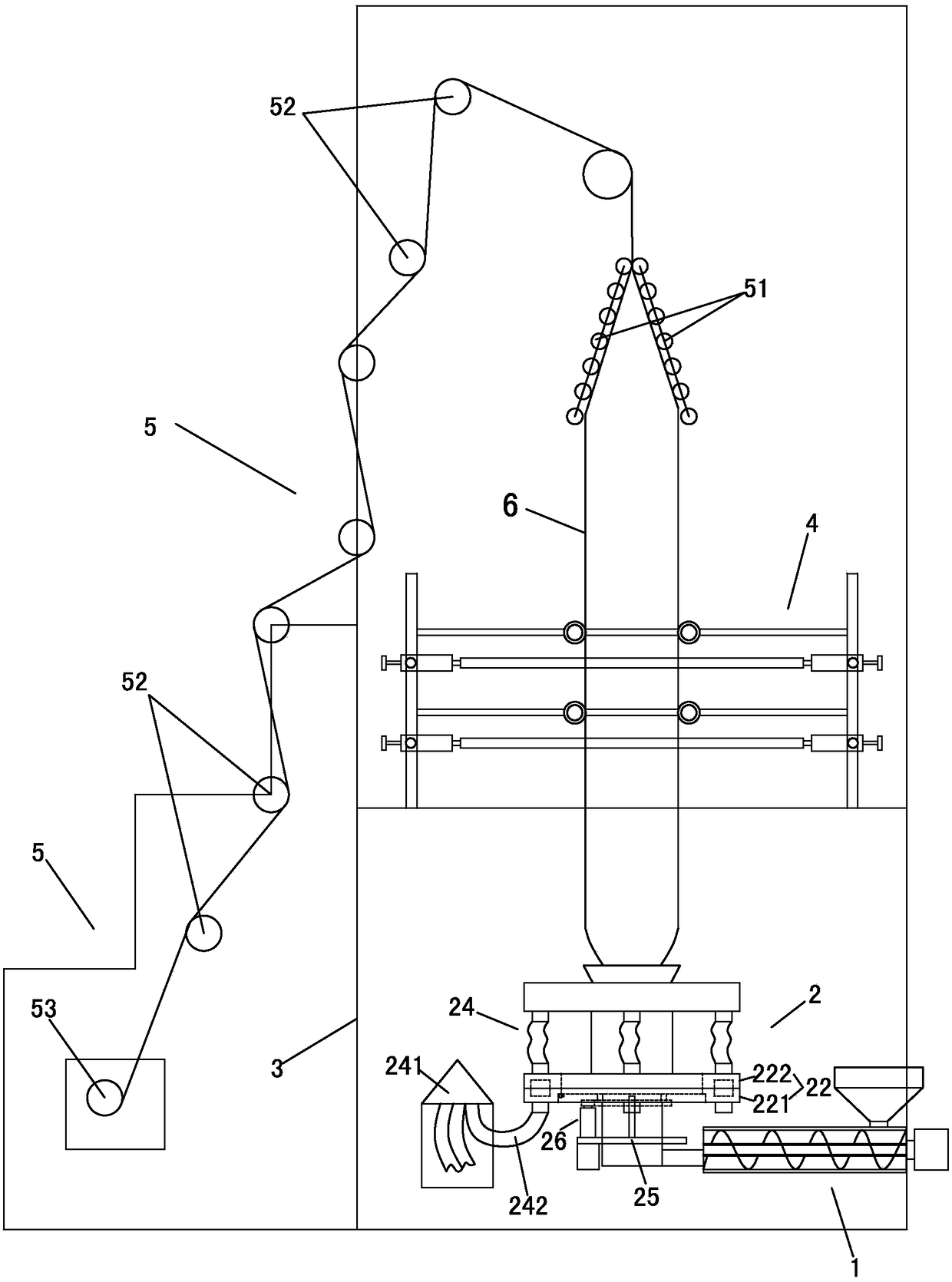

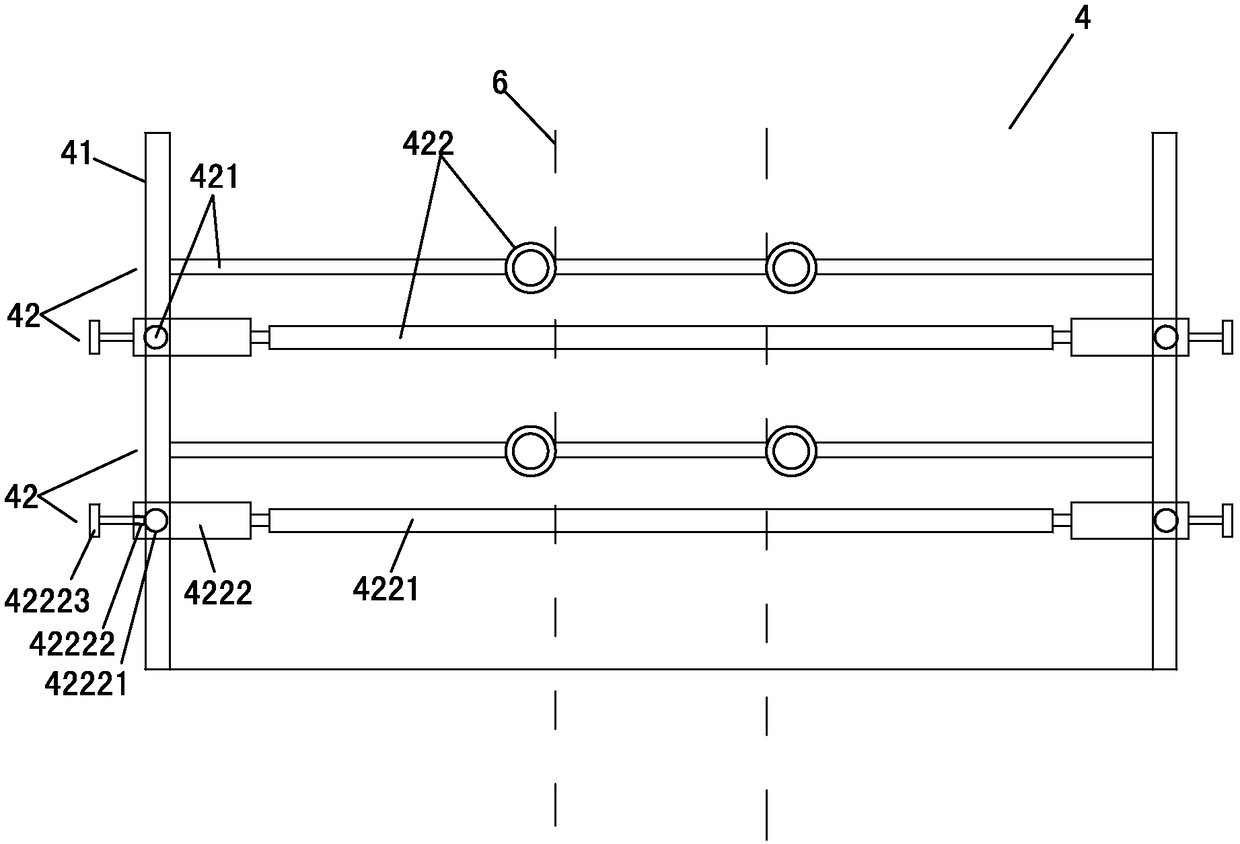

[0048] The present invention discloses a blown-up high-pressure film blowing machine, such as figure 1 As shown, it includes a melt feeding device 1, a film blowing device 2, a frame 3, a vertical limit device 4 and a coiling device 5. During production, plastic particles enter the melt feeding device 1 for melting and are transported to the blowing film device 2 Stretching out the film bubble to form a tubular film bag body 6 passes through the sag limiting device 4, and then passes through the winding device 5 to press the tubular film bag body 6 into a sheet and roll it up. The structural position connection relationship of each part will be described in detail below in conjunction with the accompanying drawings.

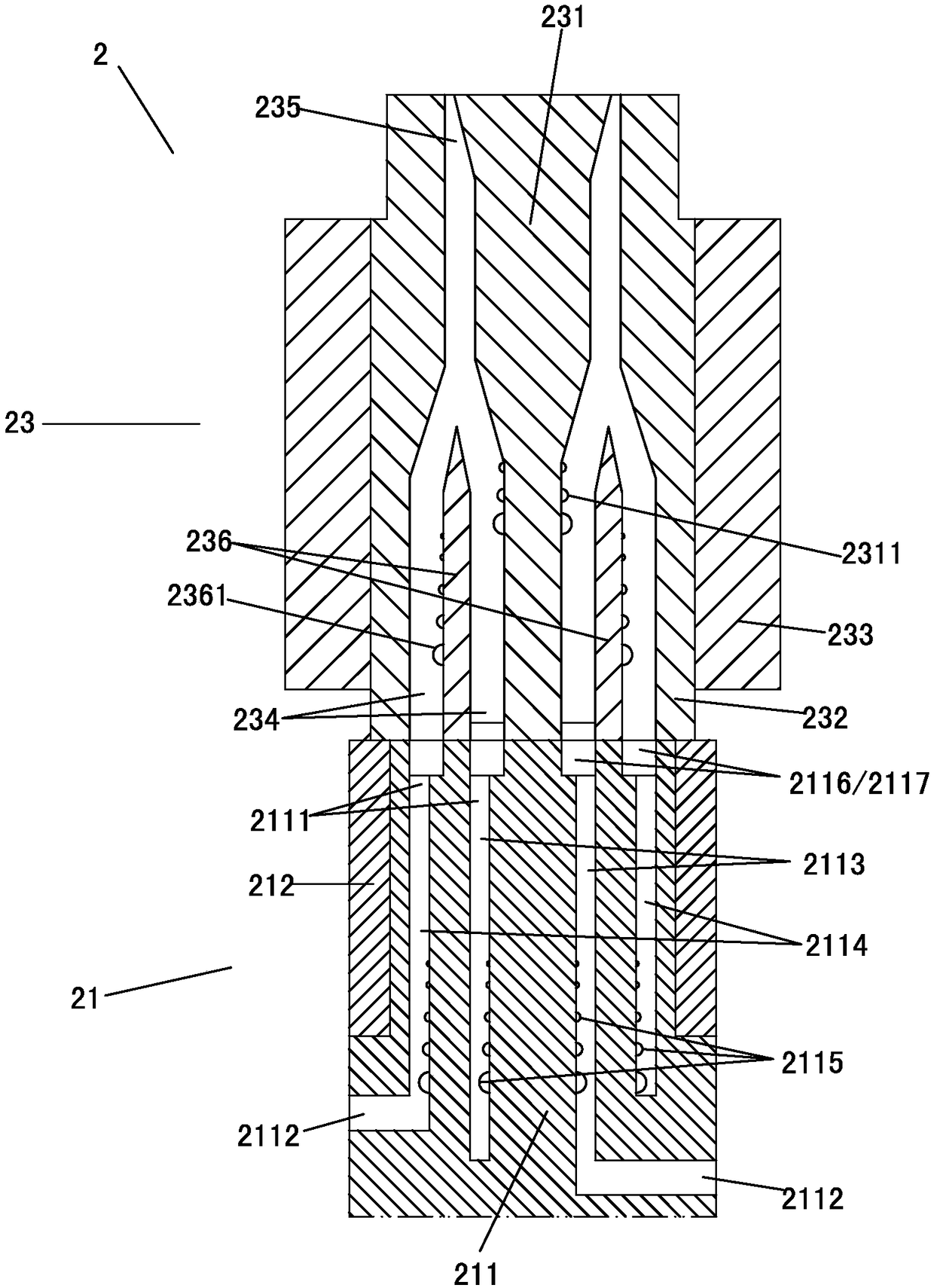

[0049] The melt feeding device 1, such as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com