Operation platform used for assisting in sorting, and operation method

An operating platform and carton technology, applied in the field of tobacco logistics industry, can solve the problems of manual elimination, reduced work efficiency, low efficiency, etc., and achieve the effect of reducing the frequency of downtime, reducing labor intensity, and speeding up operation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

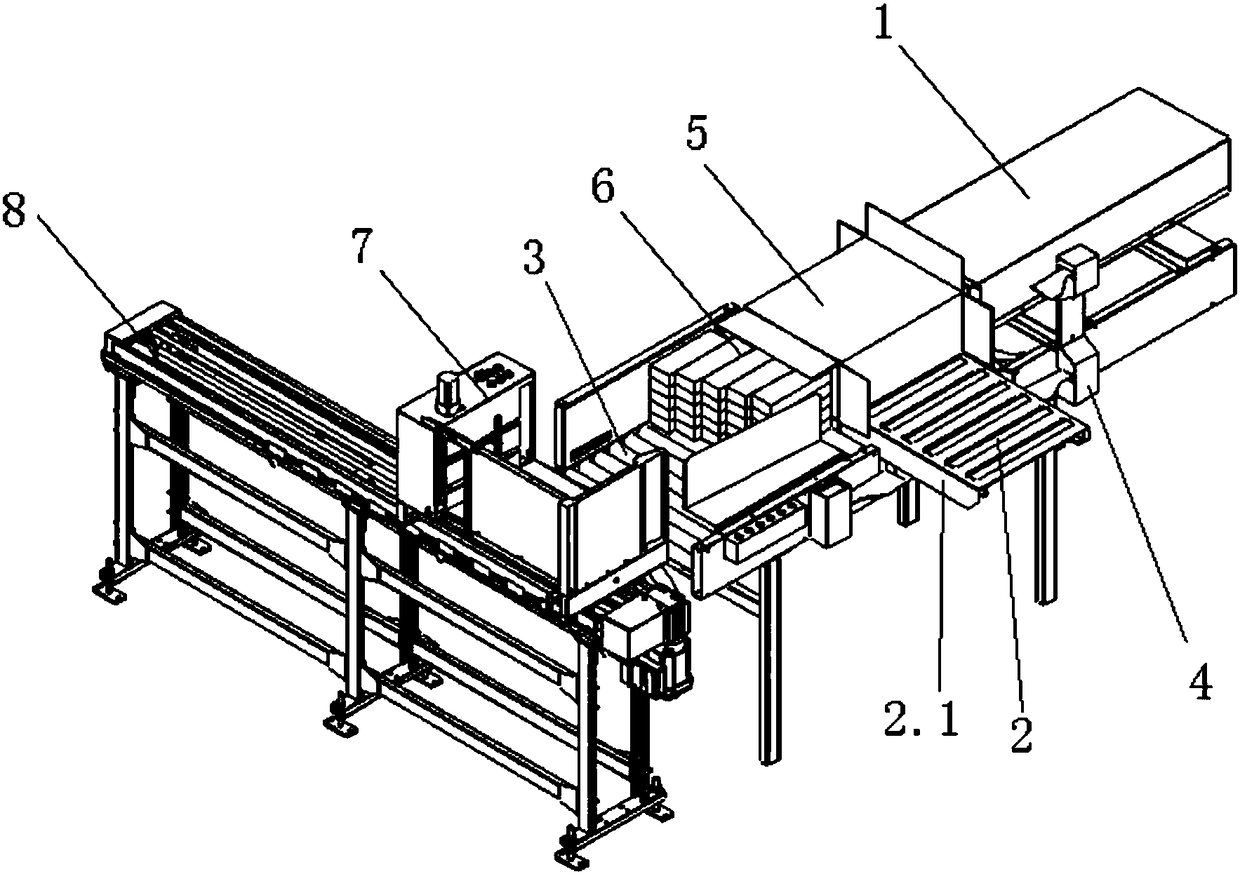

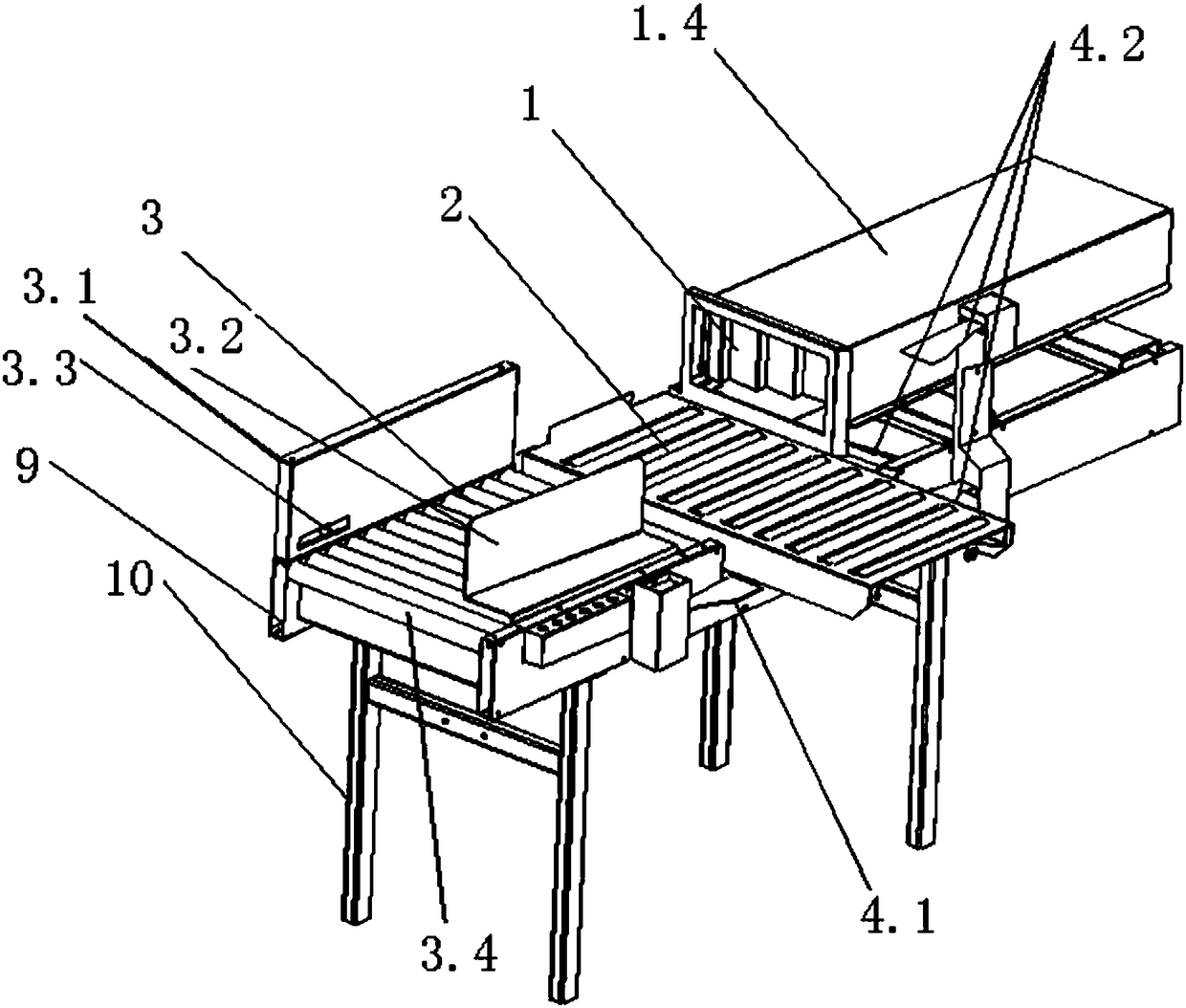

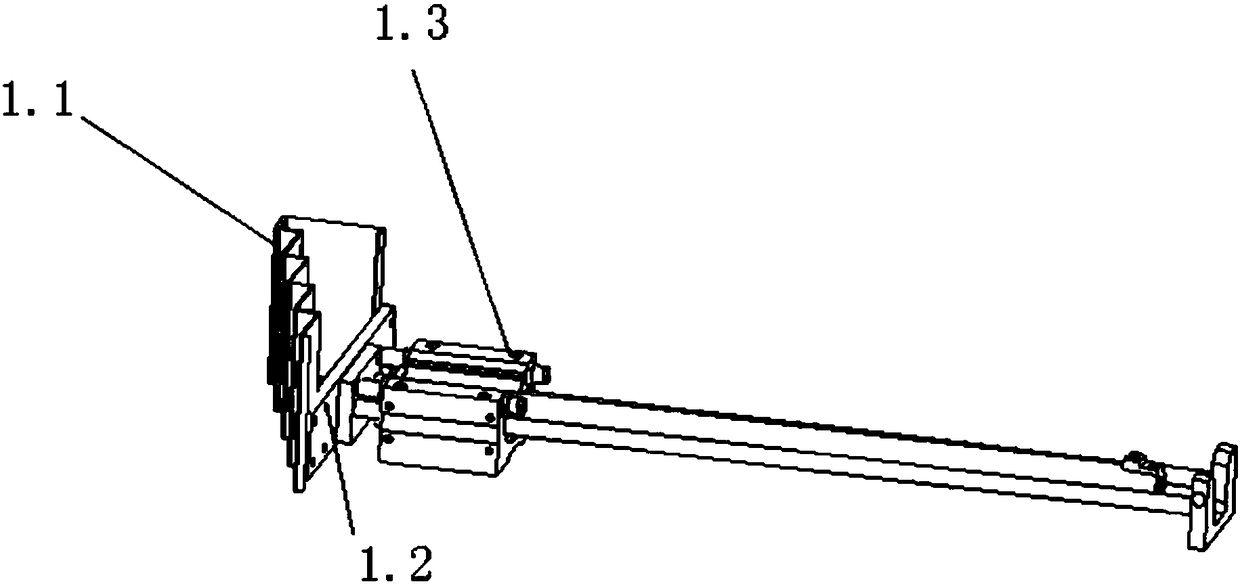

[0028] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0029] In the prior art, when it is necessary to transfer the stack of cigarettes in the cigarette box to the sorting equipment, there are two main methods: the first one is the traditional simple manual cigarette replenishment method, that is, the single stack of cigarettes is manually removed from the Take out the box and fill it into the sorting equipment; the second is to use mechanically assisted cigarette extraction, that is, mechanically assisted cigarette extraction without any form of treatment on the stack of cigarettes and directly transferred to the shuttl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com