Cathode bending separation device

A separation device and cathode technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of additional operation steps for multiple components, residual metal plates, occupying a relatively large processing site, etc., to achieve a simple and reliable structure and improve work efficiency. High efficiency and high peeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

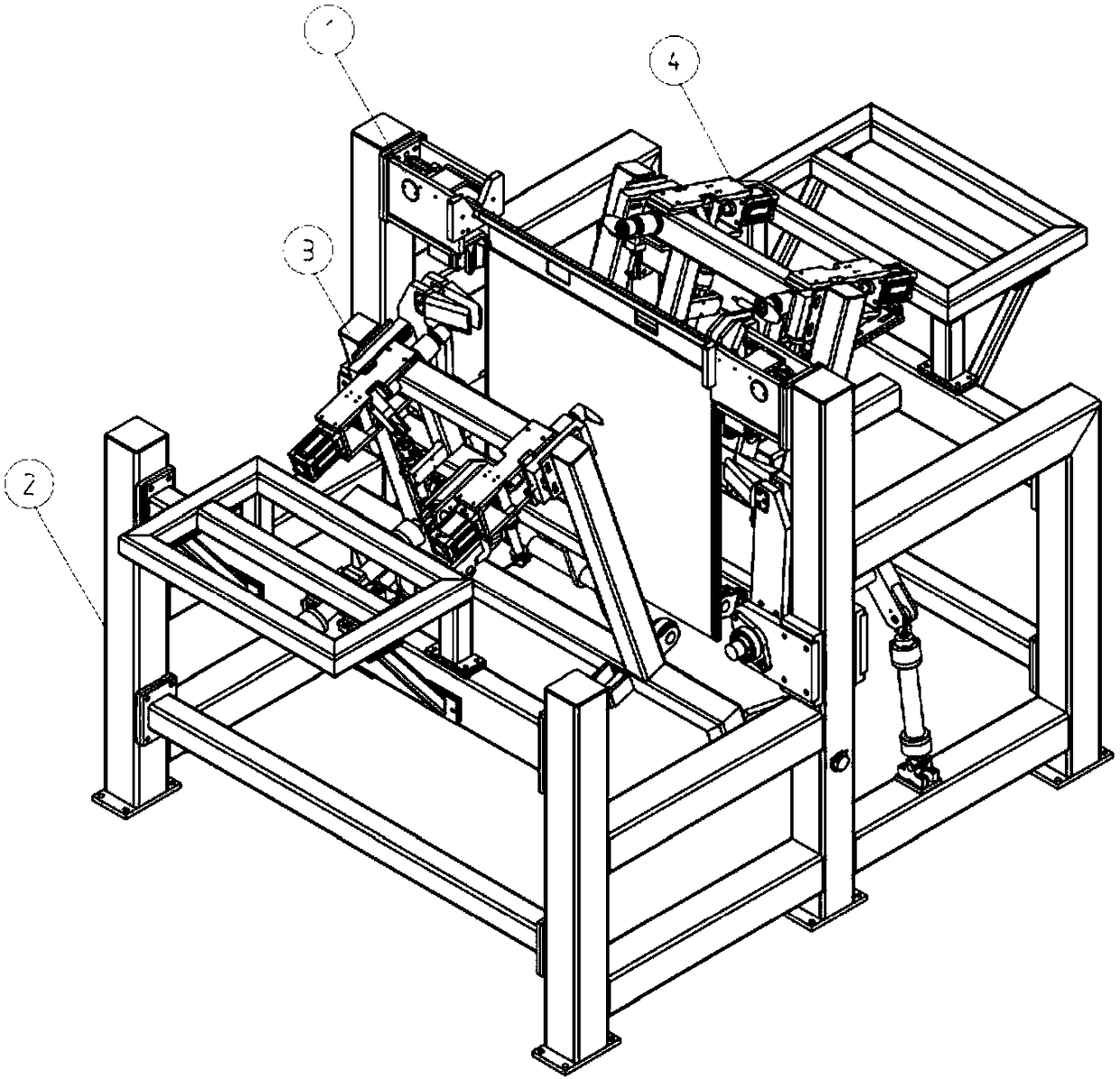

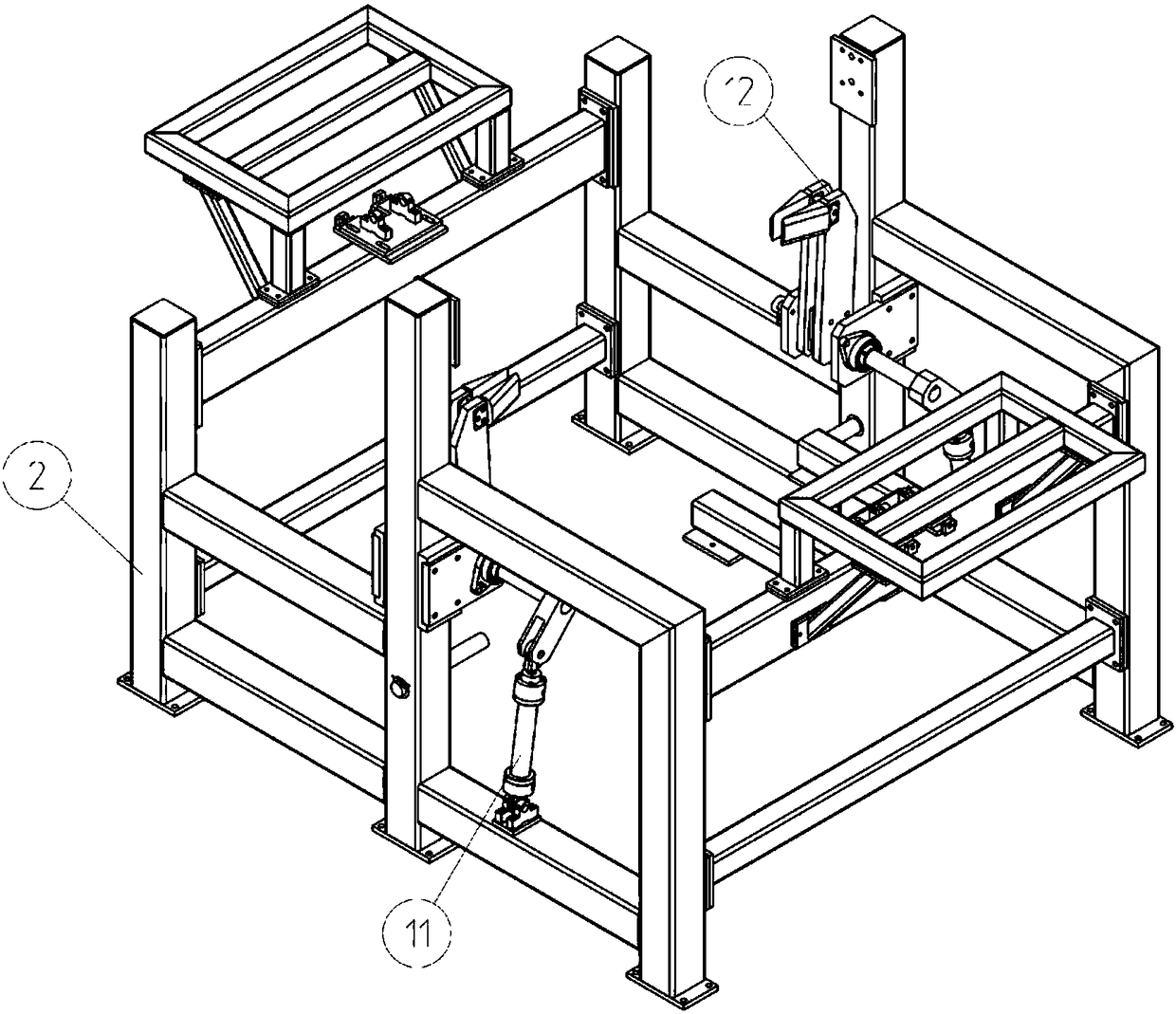

[0019] Embodiment 1: As shown in the accompanying drawings, this cathode deflection separation device mainly includes a cathode support assembly 1, a frame 2, a deflection strip assembly 3, a stripping knife assembly 4 and a driving device, and the frame 2 is provided with a stripping ax drive Oil cylinder 11, stripping ax 12, flex stripping assembly 3 is installed symmetrically on both sides of frame 2, stripping knife assembly 4 is installed on flex stripping assembly 3, cathode support assembly 1 is installed symmetrically on the middle top of frame 2. The driving device drives the opening and closing of the flexure stripping device, the rotation of the flexure body 15, and the rotation and advance and retreat of the stripping knife 18 to complete the flexure stripping operation. The frame 2 is used to install various mechanisms, and the stripping ax 12 is used to assist stripping.

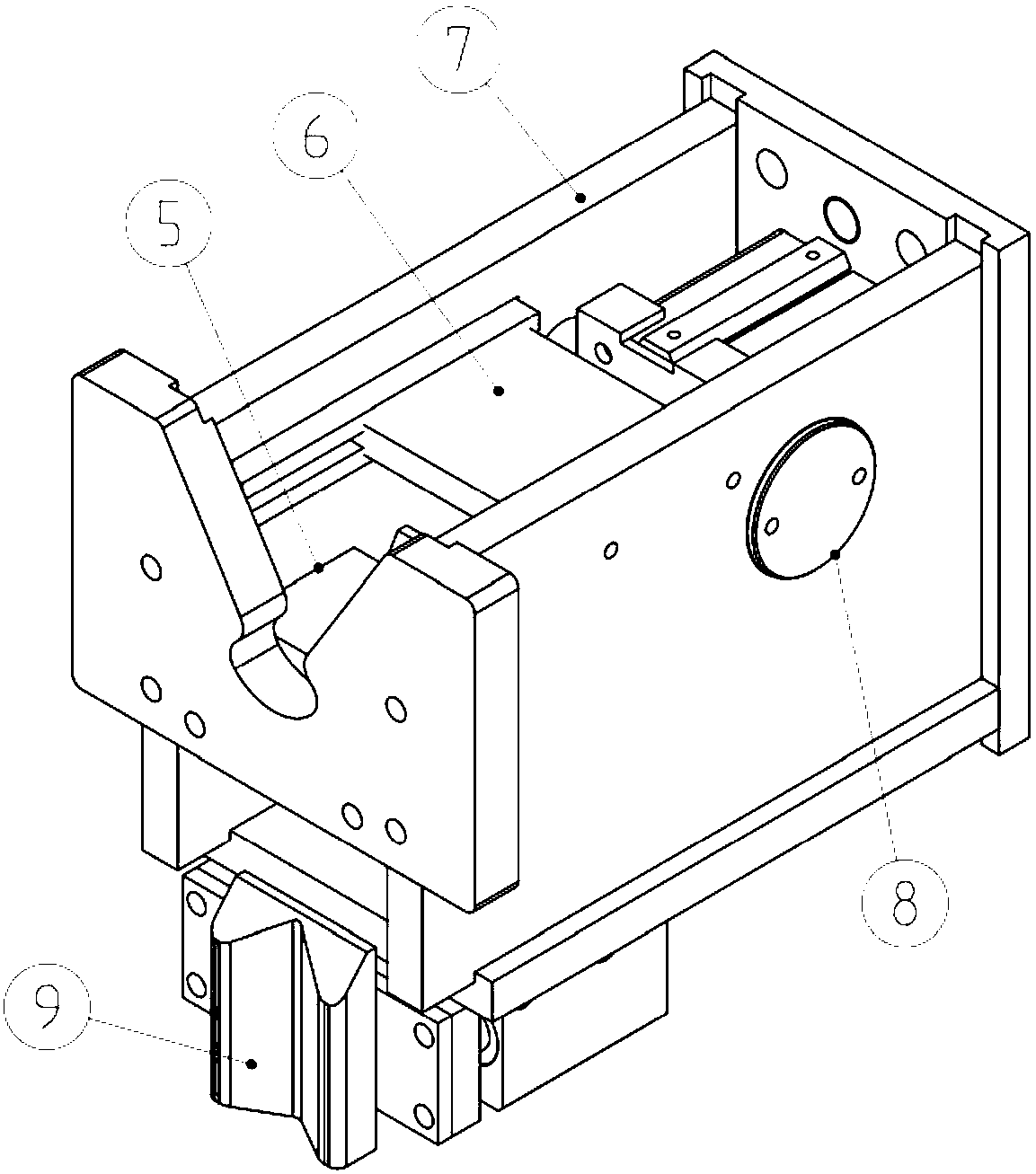

[0020] The cathode support assembly 1 is mainly composed of a limit mechanism 5, an anti-re...

Embodiment 2

[0024] Embodiment 2: When the robot puts the transferred cathode on the cathode support assembly 1, it will automatically center and adjust through the limit mechanism 5 during the descent process, and then use the side limit device 9 after the initial limit of the limit mechanism 5 Driven by the driving device, the cathode is precisely centered, and after centering, the anti-rebound mechanism 6 pushes the pressure plate out to cover both ends of the cathode under the drive of the driving device, preventing the cathode from popping out when it is peeled off.

[0025] When the cathode cannot be stripped normally, the stripping ax head 12 is driven by the stripping ax drive cylinder 11 to strip.

[0026] When the present invention is closed, the deflection lower limit ring 14 limits the bottom of the cathode, and at the same time, the flexure body 15 squeezes the cathode. Since the bottom of the cathode is limited, the cathode will generate an arc deformation to deflect the catho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com