A device for welding screw groups in the shipbuilding process

A manufacturing process and screw group technology, applied in welding equipment, manufacturing tools, auxiliary devices, etc., can solve the problems of low work efficiency and high work intensity of screw group, avoid route deviation, reduce work intensity, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

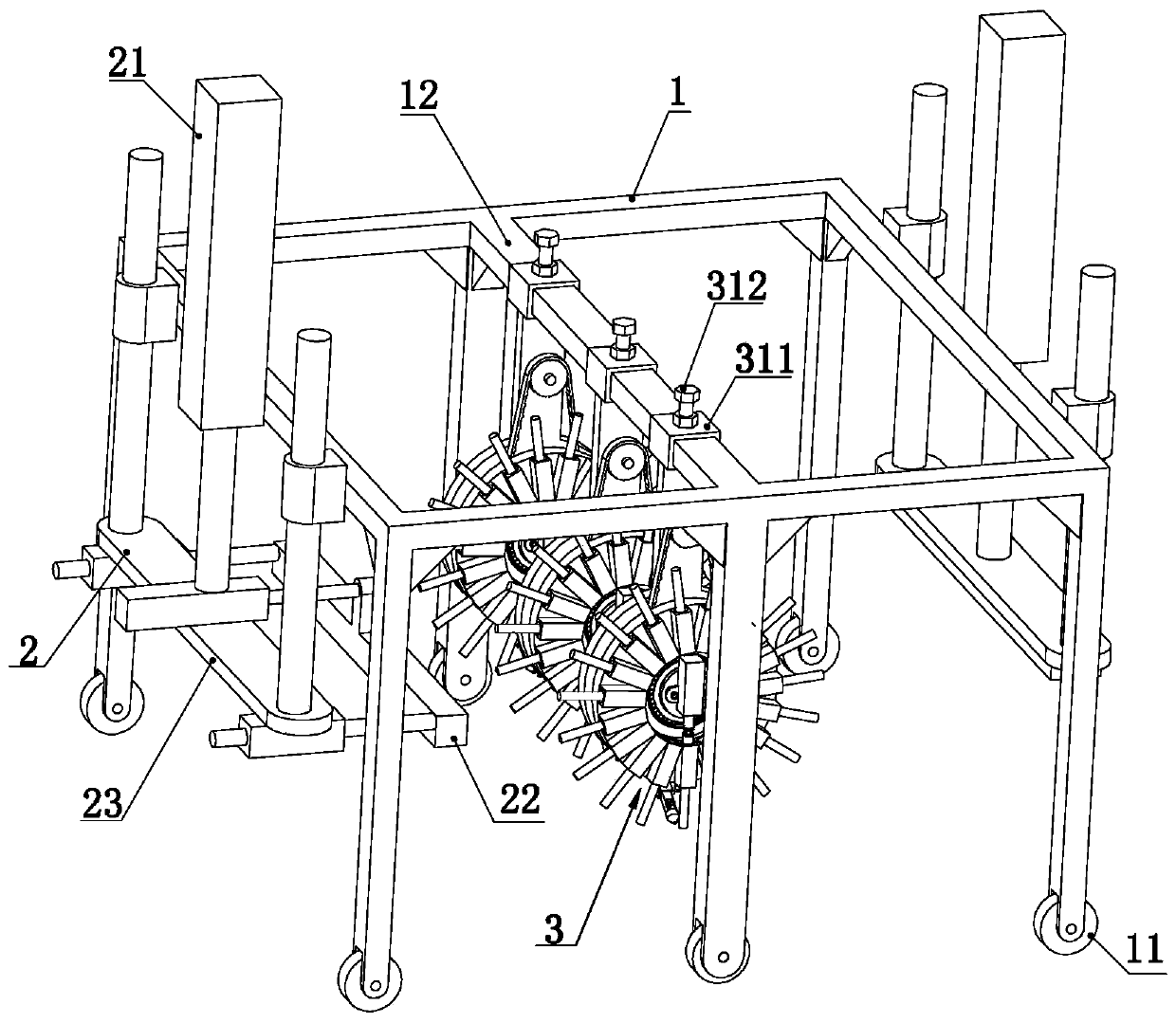

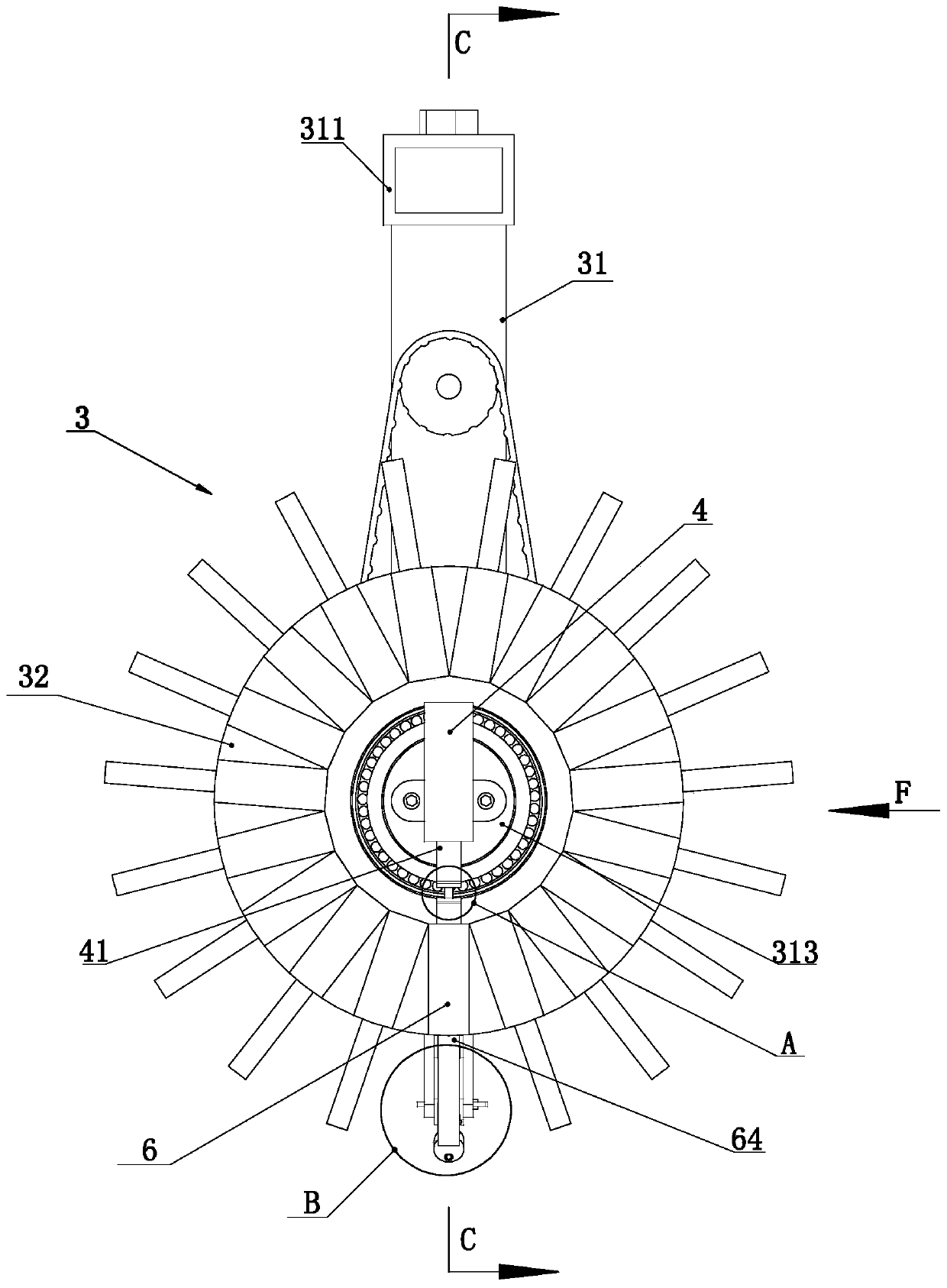

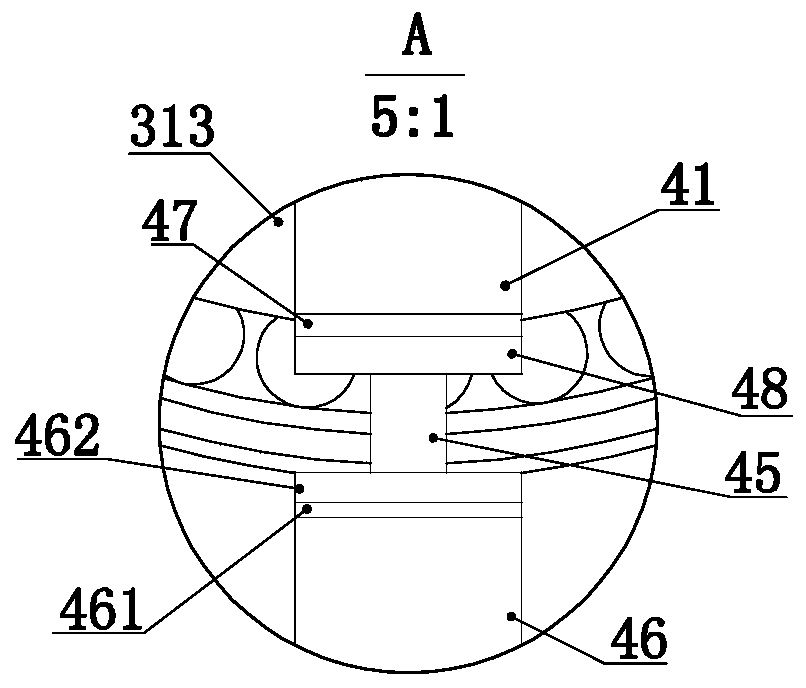

[0039] like figure 1 Shown, the present invention comprises driving frame 1, two groups of connecting frames 2 and some cloth welding machines 3, and driving frame 1 is provided with the wheel 11 that is used for convenient walking, and each connecting frame 2 is slidingly connected on driving frame 1 respectively. On, the connecting frame can slide on the driving frame 1 along the up and down direction. Each connecting frame is distributed along one front and one rear. Each connecting frame 2 and the driving frame 1 are respectively provided with lifting drivers 21 for driving the corresponding connecting frame 2 to slide up and down. Each connecting frame 2 is connected with an electromagnetic Iron 22.

[0040] like figure 1 As shown, the electromagnet 22 located on one and / or the other connecting frame 2 is slidably connected to the corresponding connecting frame 2 of the electromagnet 22, and the electromagnet 22 can slide in the front and rear direction on the correspon...

Embodiment approach 2

[0054] The difference between Embodiment 2 and Embodiment 1 lies in the arrangement of the welding head.

[0055] like Figure 12 and Figure 13 As shown, the bottom of the fixed disk is connected with a mounting frame 51, and the mounting frame 51 is slidably connected with a fixed ring 57. The fixed ring 57 can slide up and down on the mounting frame 51. A fixed ring driver 58 that drives the fixed ring 57 to slide vertically. The fixed ring 57 is provided with a moving ring 59, and the moving ring 59 is connected to the fixed ring 57 in rotation. The axis of the fixed ring 57 is arranged along the up and down direction. ring drive 591 . The moving ring 59 is connected with a welding rod 54, and the welding rod 54 is provided with a welding wire hole for passing the welding wire. The welding rod 54 is provided with a conveying wheel set for extruding and conveying the welding wire at one end of the welding wire hole. For example, the conveying wheel set includes two conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com