Hand-pushing type joint beautifying machine

A beautiful sewing machine, hand-push technology, applied in the direction of construction, building construction, etc., can solve the problems of increasing the labor intensity of craftsmen, increasing the difficulty of work, overfilling or missing filling, etc., to reduce labor injuries and improve the aesthetics of finished products , to ensure the effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

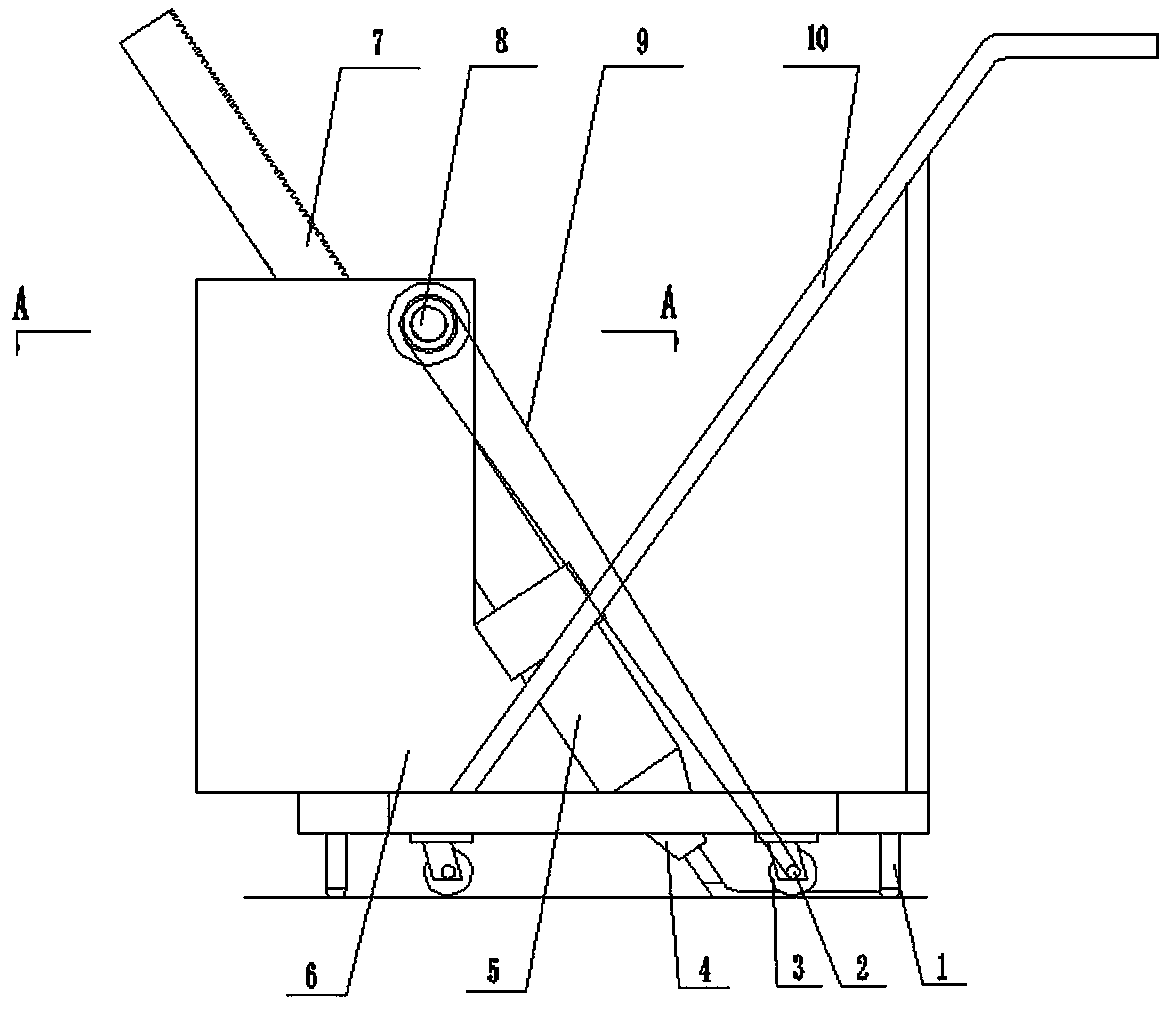

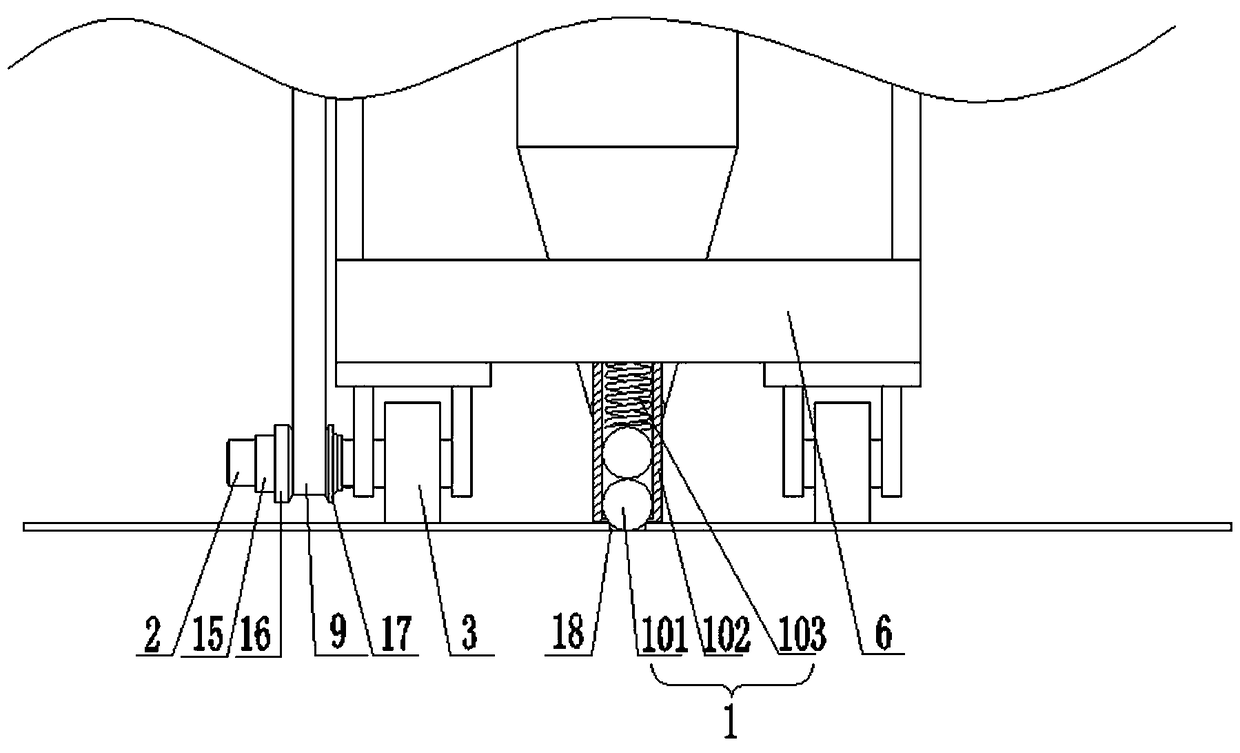

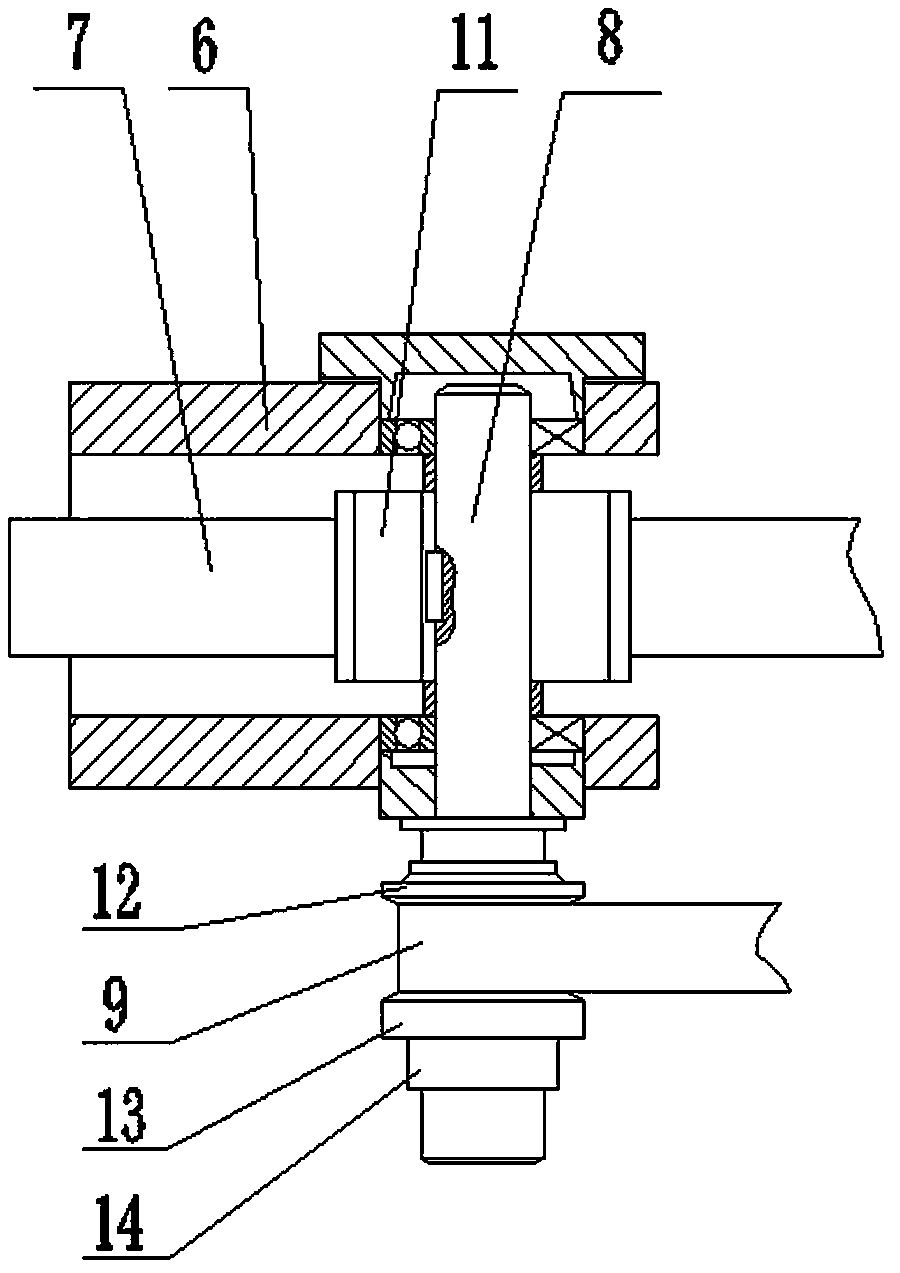

[0022] Such as Figure 1 to Figure 3 As shown, a hand-push beauty sewing machine of the present invention includes a trolley 6 and a beauty treatment agent cylinder 5 arranged on the trolley 6 and used to hold the beauty treatment agent. The bottom of the cart 6 is provided with four traveling wheels 3 and two guide wheels 1 at intervals, and the four traveling wheels 3 are distributed in a rectangle for driving the cart 6 to advance. A handrail 10 is also provided at the rear end of the trolley 6 in the direction of travel, which is convenient for craftsmen to hold the handrail 10 to push the trolley 6 to advance. The two guide wheels 1 are respectively arranged at both ends of the cart 6 in the direction of travel, and are used to partially clamp into the tile joint 18, and play a guiding role in the travel of the cart 6, which is beneficial for the beautifying agent to squeeze into the tiles along a straight line Seam 18 in. Wherein the guide wheel 1 that is positioned at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com