The replacement method of concrete sleepers in the tunnel and bridge section of the business line

A technology for concrete and sleepers, which is applied to the replacement of concrete sleepers in bridge sections and in the field of business line tunnels, can solve problems such as the inability to meet operational requirements, and achieve the effect of improving sleeper replacement efficiency and replacement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

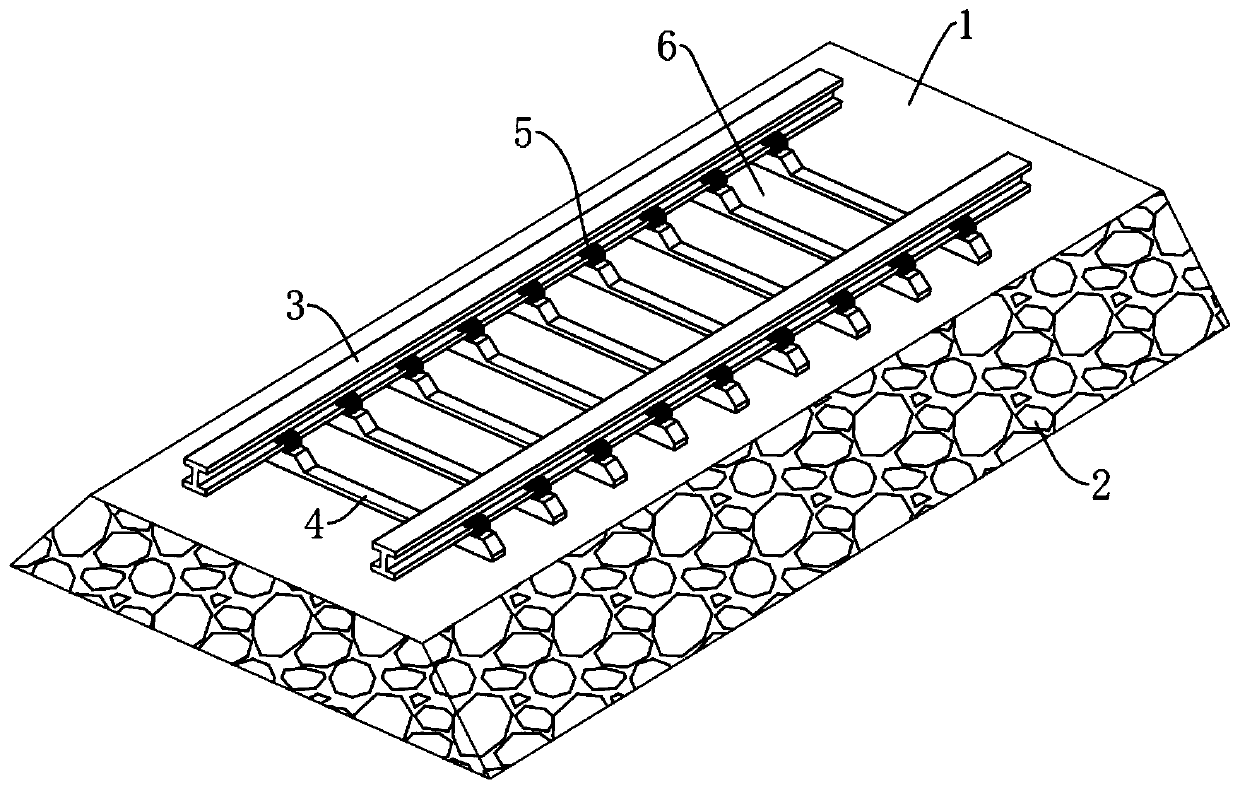

[0040] A method for replacing concrete sleepers in a tunnel section of a business line provided in this embodiment includes:

[0041] To unload the sleeper, unload the sleeper 4 to the ditch on both sides of the first section of the roadbed at both ends of the tunnel in advance, arrange it neatly and anchor it;

[0042] For construction preparation, first determine the position of "opening the door", remove or remove the anti-climbing equipment and gauge rods that affect the operation, and mark the rail waist of track 3 with paint according to the position of the sleepers according to the design. Sprinkle water on the ballast bed in the replacement section, and install temporary lighting equipment at the same time. According to the compaction or dirtiness of the ballast bed in the replacement section, add ballast 2 with a ballast repair vehicle;

[0043] The sleepers are transported back, and the new sleepers are transported back into the tunnel with a flatbed car or a monorai...

Embodiment 2

[0066] A method for replacing concrete sleepers in the bridge section of the business line provided in this embodiment includes:

[0067] Before changing pillows, manually remove the guard rails on the bridge by using the pillow changing skylight point, and push the inside point to the roadbed on both sides of the line outside the bridge head with a flatbed truck, outside the safety limit.

[0068] To strengthen the beam body, conduct on-site investigation on the anchorage strength, corrosion degree and damage degree of the U-shaped bolts of the steel bracket, and make corresponding marks. To check the transverse connection of concrete beams, and to consider whether the increase of eccentric load on the beam body will affect its stability, it is necessary to have the investigation and experiment results of relevant units, and take corresponding reinforcement measures.

[0069] Among them, it is forbidden to stack sleepers and bridge sleepers on the sidewalk, and bridge sleeper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com