Foil bearing

A technology for bearings and bearing surfaces, applied to bearings, bearing components, shafts and bearings, etc., can solve the problem of high cost in manufacturing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

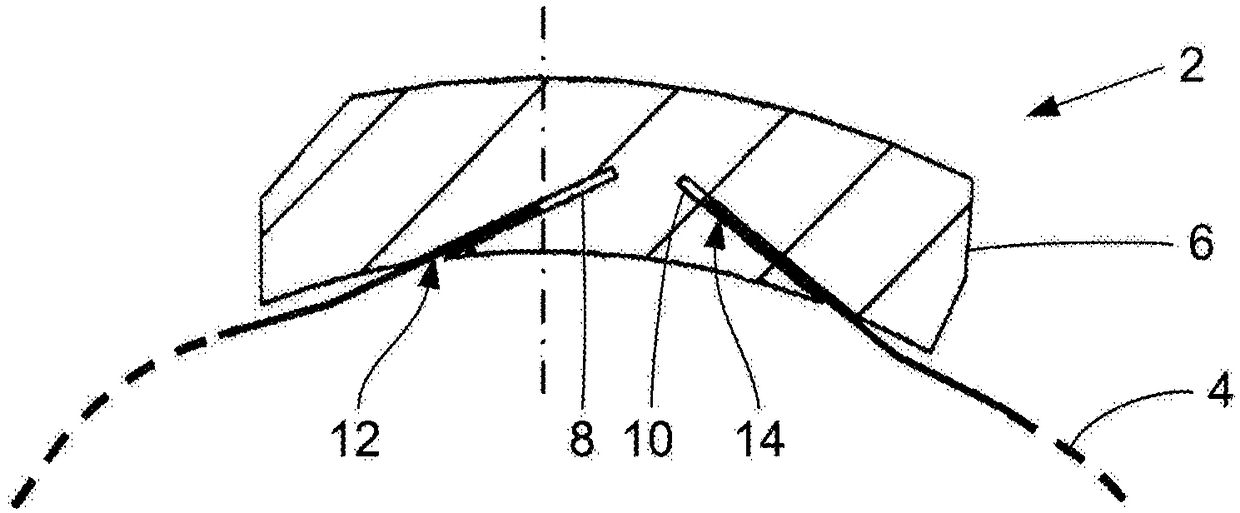

[0023] therefore, figure 1 A partial sectional view of the film bearing 2 is shown in the region of the fastening device for the cover film 4 , for example a single-sided bearing. On the inner side of the sleeve-shaped bearing housing 6 are formed plug-in grooves 8 , 10 oriented obliquely from the inside to the outside, end edges 12 , 14 bounding the cover film 4 in the circumferential direction and extending substantially in the circumferential direction. Fits into plug slot. The depth of the plug-in grooves 8 , 10 is greater than the insertion depth of the associated end edges 12 , 14 in the case of an unloaded cover film, wherein the plug-in grooves 8 , 10 each have a sliding fit. The associated end edges 12 , 14 are accommodated. When the cover film 4 is subjected to mechanical or thermal loads, the end edges 12 , 14 can be displaced into the associated plug-in grooves 8 , 10 so that the cover film 4 can be adapted to the load-induced stresses of the film system. deform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com