A radio frequency coaxial cable assembly welding device

A technology of radio frequency coaxial cables and welding devices, applied to electrical components, circuit/collector components, connections, etc., can solve problems such as short delivery cycle, low defective rate, and increased manufacturer's quality cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

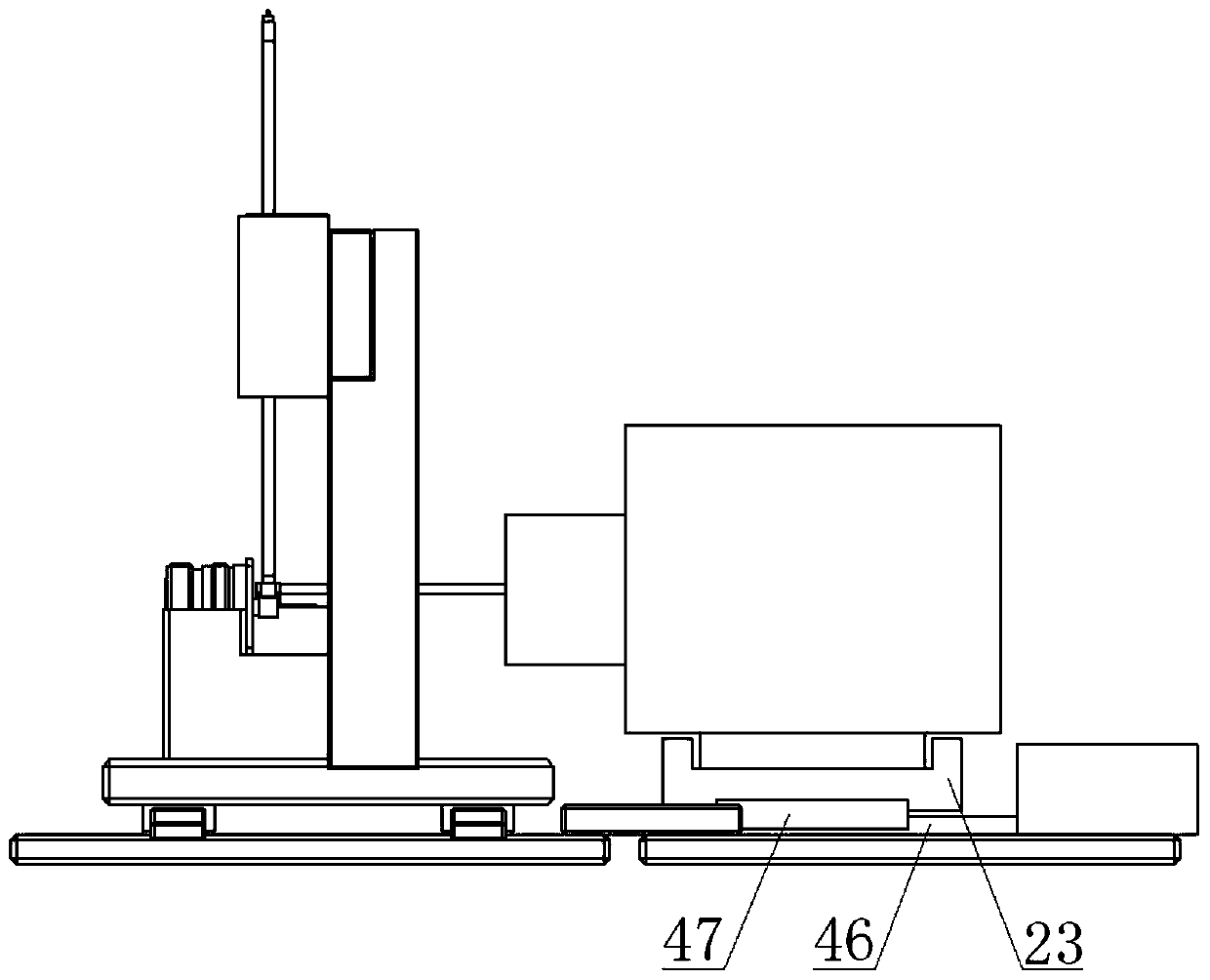

[0034] refer to Figure 1 to Figure 4 As shown, in this embodiment, there is a detachable fixed connection between the welding base 36 and the positioning base 35; The direction is perpendicular to the length direction of the positioning base 35 . The length direction of the positioning base is the sliding direction of the base 34 along the positioning base 35 .

[0035] Such as Figure 4 , the welding base 36 and the positioning base 35 are detachably and fixedly connected by connecting components, the connecting components include connecting blocks 48 (49) and bolts; the two sides of the welding machine base 23 are respectively provided with a connecting component; in each connecting component, the connecting One end of the block is fixedly connected to the positioning base, and the other end is provided with a waist-shaped hole 481 (491), and the screw rod of the bolt passes through the waist-shaped hole and then is threadedly connected to the welding base. The setting o...

Embodiment 2

[0043] refer to Figure 5 , This embodiment is different from Embodiment 1 in that the two connector positioning seats are both straight connector positioning seats, which can realize the welding of two straight-through RF coaxial cable assemblies.

[0044] Example 2

[0045] refer to Figure 6 , This embodiment is different from Embodiment 1 in that the two connector positioning seats are both straight elbow connector positioning seats, which can realize the welding of two right-angle bending RF coaxial cable assemblies.

[0046] When the present invention is applied, the connector to be welded and the cable can be respectively fixed between the connector fixing seat and the clamp block and the chuck, and the cable is docked with the cable connection end of the connector, and then the base and the positioning base are adjusted. The relative position between the seats, so that the welding head of the welding machine is aligned with the connection point between a pair of cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com