A kind of connection method of ceramic biscuit

A technology of ceramic green body and connection method, which is applied in the field of ceramics, can solve problems such as lack of detailed description and affect the effect of ceramic connection, and achieve the effects of prolonging timeliness, avoiding inclusion of air bubbles, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

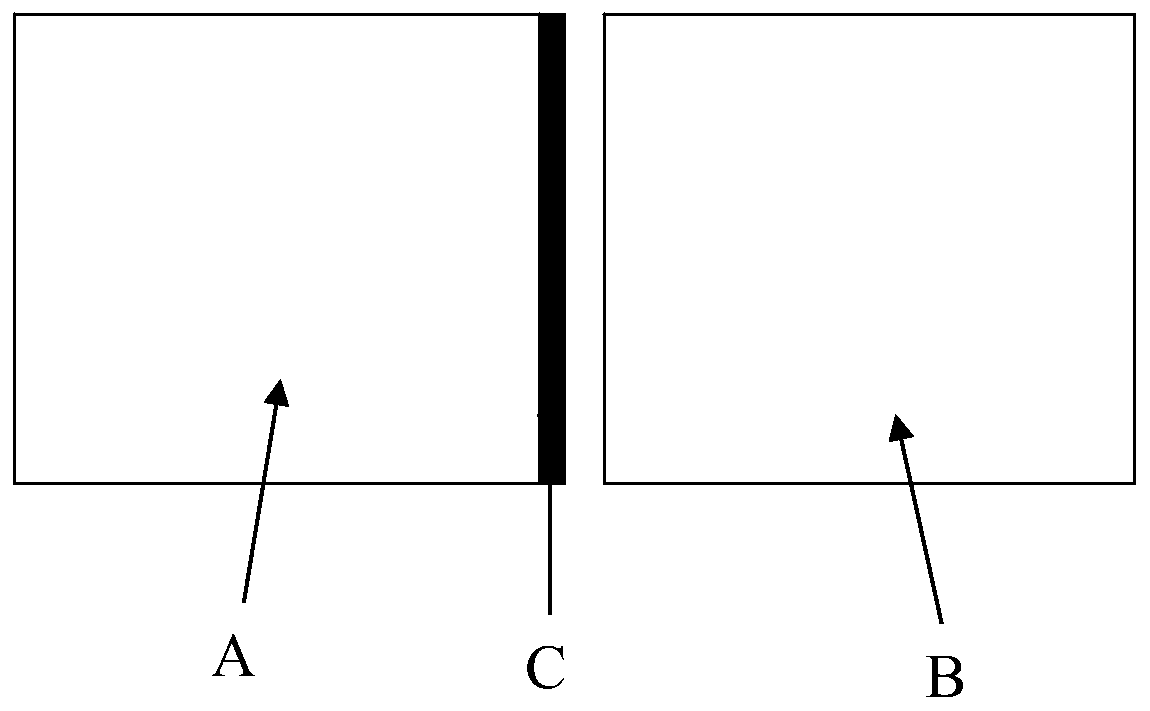

[0032] combine figure 1 As shown, A and B are two silicon carbide green bodies respectively, which are respectively recorded as the first silicon carbide green body and the second silicon carbide green body. The connection method between the two is as follows:

[0033] (1) Treatment of silicon carbide blanks

[0034] Firstly, the surfaces of A and B to be connected are processed into a plane, and the floating ash on the surface is cleaned with ethanol and then dried. Brush the thermoplastic phenolic resin solution with a mass fraction of 7% on the surface, and set aside.

[0035] (2) Preparation of connecting slurry

[0036] Prepare 20% of silicon carbide micropowder with the same particle gradation as A and B; thermoplastic phenolic resin 30%; acrylamide 5%; ethanol 30%; polyethylene glycol 200 (PEG 200) 5%, hexamethylene tetra Amine 10%; the above proportions are volume ratios, and the sum of the percentages is 100%. After the above materials are mixed, silicon carbide b...

Embodiment 2

[0042] It is basically the same as Example 1, except that in step (3), the thickness of the tape-cast connection slurry is 3 mm, and then the first silicon carbide green body A and the tape-cast connection layer C are placed simultaneously Place it in a 50°C environment for 5 hours, then take it out, and let it air out at the same temperature as room temperature. In step (4), a pressure of 0.5 MPa is applied after the surface to be connected of the second silicon carbide green body B is bonded to the connection layer C, and the connected green body is heated to 200° C. in a heating furnace while maintaining the pressure, thereby Complete the connection between the silicon carbide green bodies.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com