Oil tank anti-theft system

An anti-theft system and fuel tank technology, applied in anti-theft vehicle accessories, layout combined with internal combustion engine fuel supply, power units, etc. Advanced problems, to achieve the effect of ingenious structure, low production cost and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

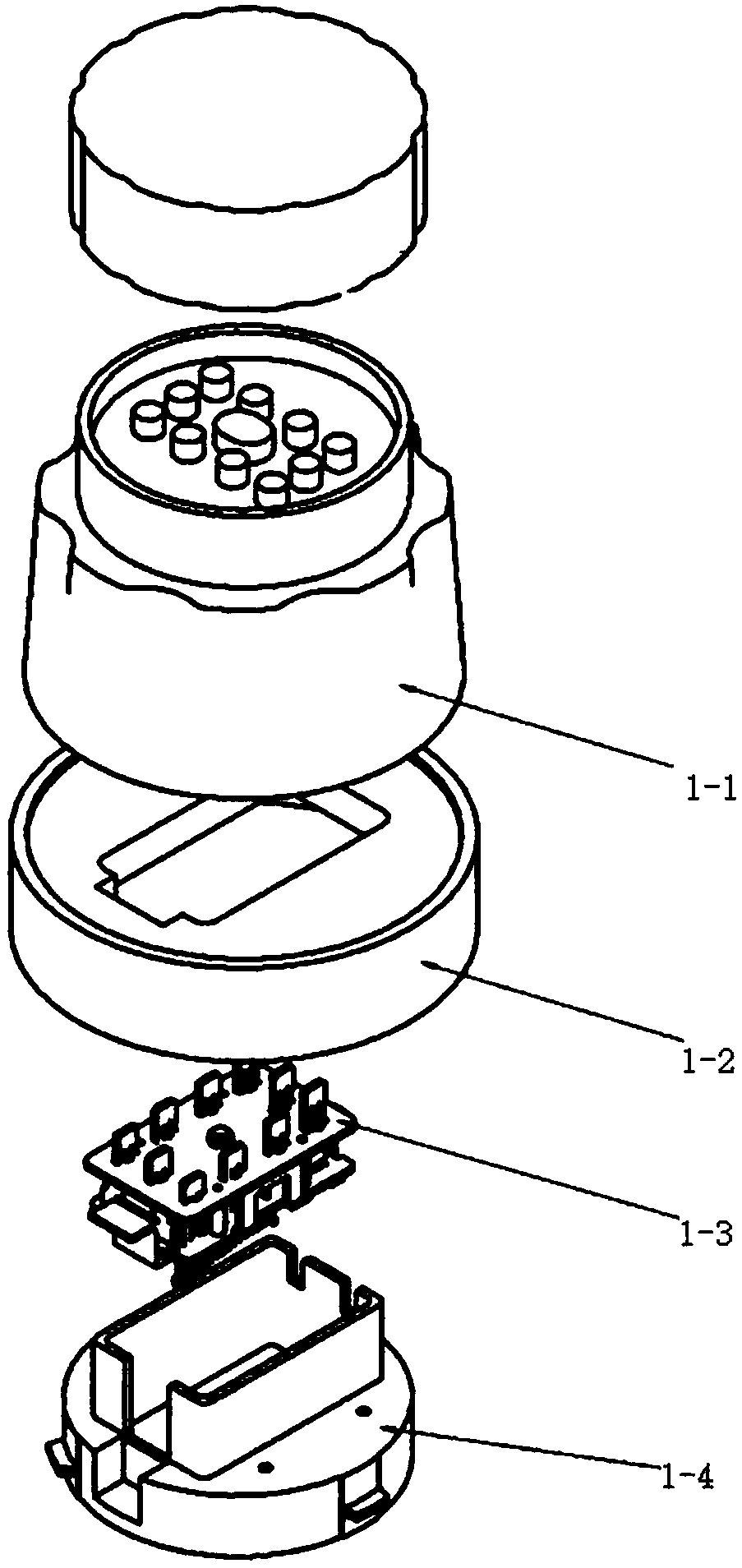

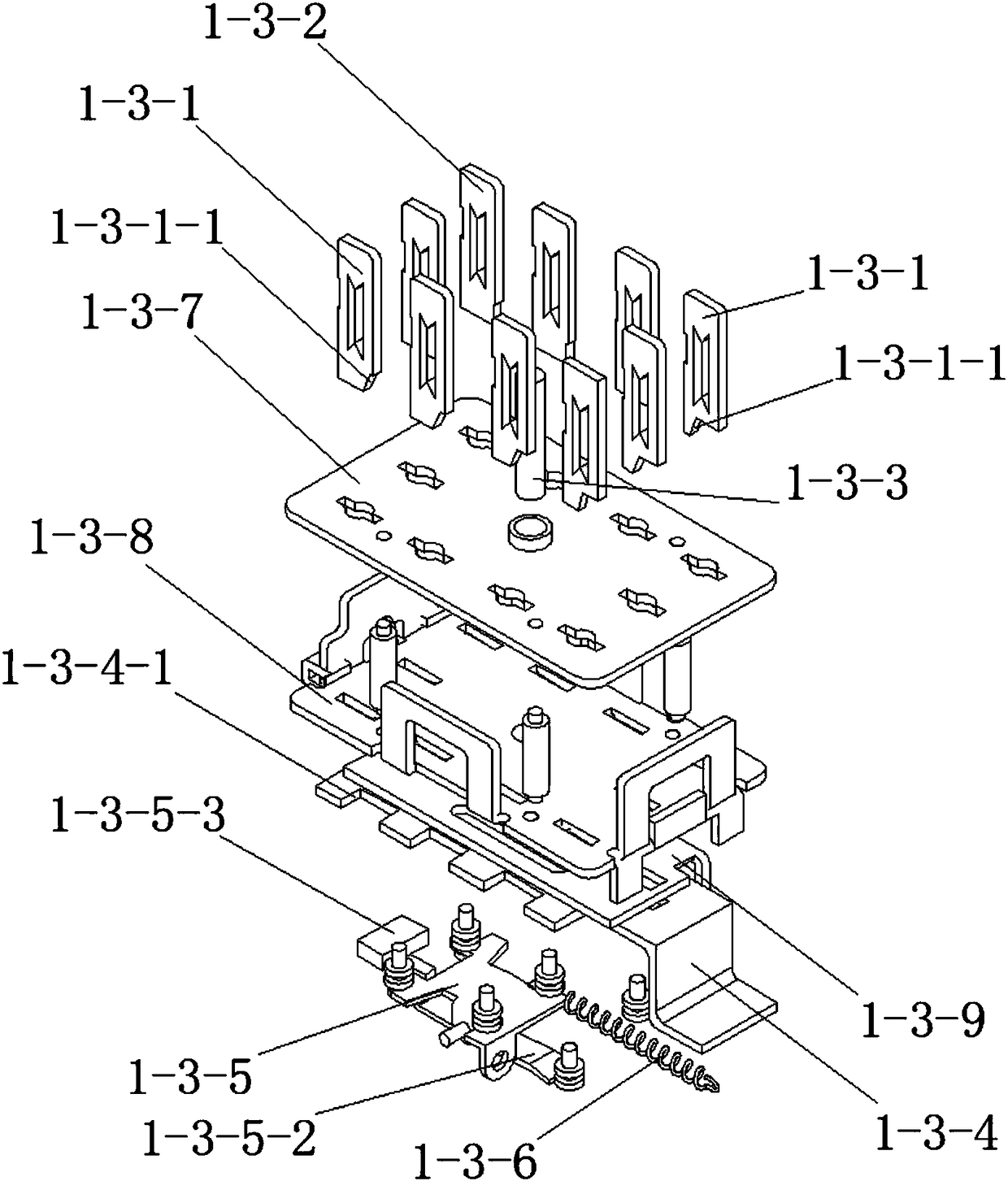

[0029] See Figure 1 to Figure 6 , the fuel tank anti-theft system of the present embodiment includes a mechanical combination lock 1 . The mechanical combination lock 1 includes a button fixing seat 1-1, a connecting cover 1-2, a mechanical lock cylinder 1-3 and a chuck 1-4.

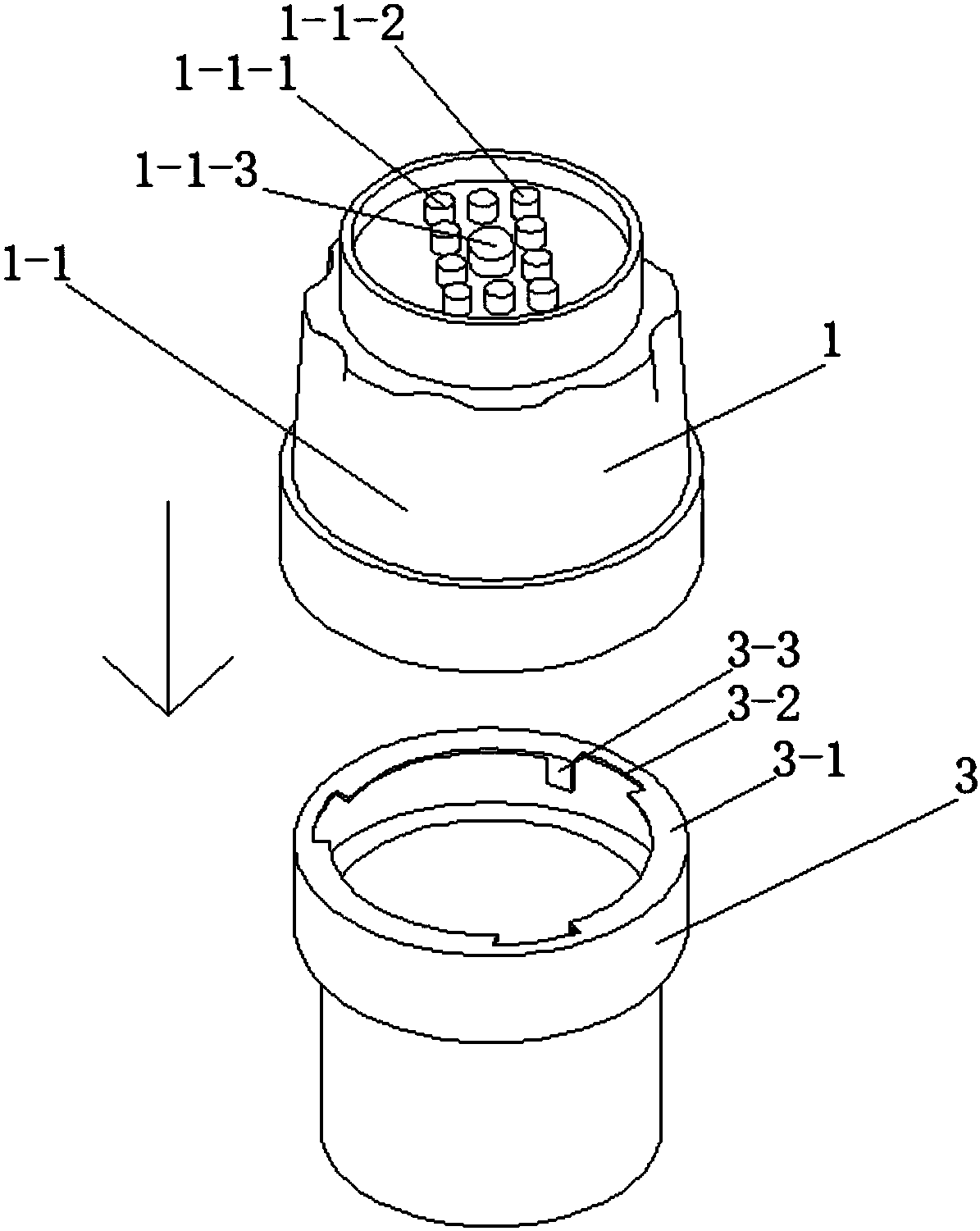

[0030] Buttons are arranged on the top of the button holder 1-1. The connecting cover 1-2, the mechanical lock cylinder 1-3 and the chuck 1-4 are sequentially arranged in the button fixing seat 1-1, and the mechanical lock cylinder 1-3 is installed on the chuck 1-4. The button fixing seat 1-1 cover is arranged on the oil filling port 3 of the fuel tank, and seals the oil filling port 3 of the fuel tank. Chuck 1-4 stretches in the oil filling port 3 of oil tank. The buttons include multiple unlocking buttons 1-1-1, multiple code destroying buttons 1-1-2 and locking buttons 1-1-3. Press the unlock button 1-1-1 sequentially according to the unlock password sequence to drive the mechanical lock cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com