Width-adjustable rail car walking mechanism

A technology of traveling mechanism and rail car, which is applied in the direction of wheels, wheels, and vehicle parts characterized by rail running parts, which can solve the problems of easy wear or jamming of rail cars, reduce wear, improve flexibility, and prevent jamming dead effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

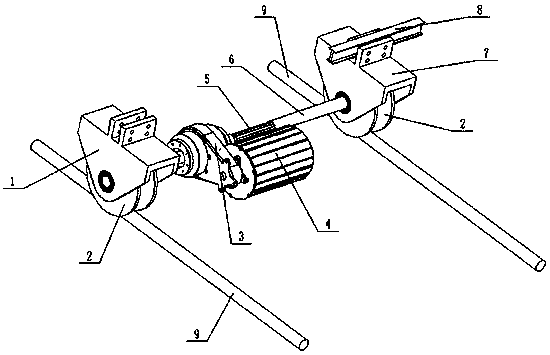

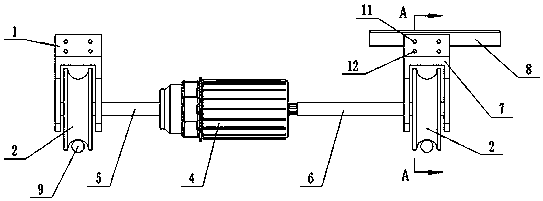

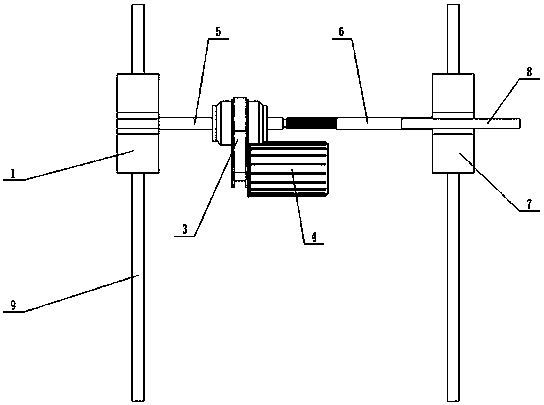

[0028] A rail car running mechanism with adjustable width, such as Figure 1-5 As shown, it includes a track running part and a width adjusting part arranged on the track running part. Wherein, the rail running part includes a driving device, a power shaft and a rail wheel 2, the rail wheel 2 travels on a set of rails 9, and the rail wheel 2 is connected to the power shaft through a bearing seat. In this example, the power shaft includes a spline shaft 5 and a sleeve shaft 6. The sleeve shaft 6 and the spline shaft 5 are connected by a sliding spline, and both can move left and right relatively, while the sleeve shaft 6 and the spline shaft 5 The circumferential direction is positioned by splines. The left end of the spline shaft 5 is provided with a left end track wheel, and the left end track wheel is rollingly connected with the spline shaft 5 through the fixed bearing seat 1. The right end of sleeve shaft 6 is provided with a right end track wheel, and the right end trac...

Embodiment 2

[0035] Such as Figure 6-9As shown, the difference from Embodiment 1 is that the installation positions of the roller shaft 12 and the deep groove ball bearing 10 on the roller shaft 12 are different. Specifically, in Embodiment 2, the deep groove ball bearing 10 is fixed in the through hole at the lower end of the vertical plate on the mobile bearing seat 7, the outer peripheral surface of the roller 12 is in rolling contact with the lower end surface of the lower plate of the connecting plate, and the roller 12 Roll fit with the lower plate of the connecting plate.

[0036] The width-adjustable rail car traveling mechanism of the present invention is suitable for occasions where the track installation accuracy is low such as farmland and orchards, so as to automatically adapt to changes in the width of the track.

[0037] Embodiment 3 of a width-adjustable railcar running mechanism is different from Embodiment 1 in that a sleeve shaft 6 is also provided at the left end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com