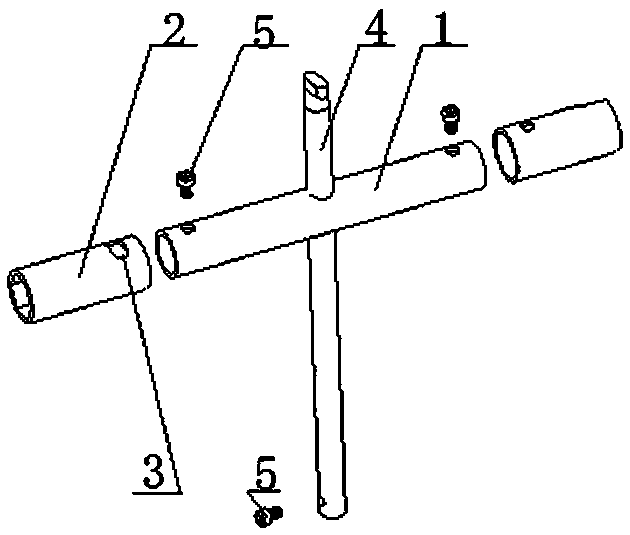

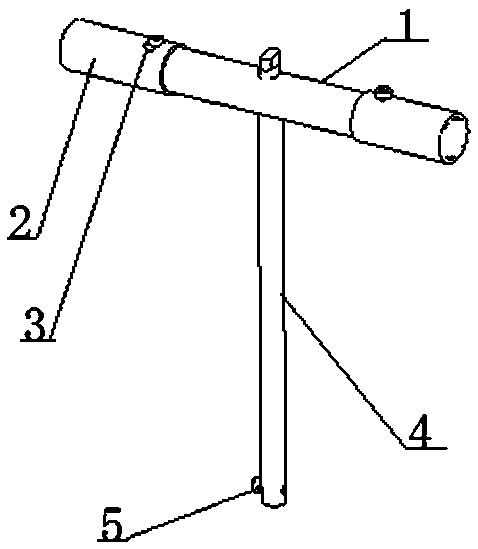

Spanner and clamping-and-holding assembly thereof

A clamping piece and wrench technology, applied to wrenches, manufacturing tools, wrenches, etc., can solve the problem of low working efficiency of conventional wrenches, achieve large torsional resistance and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

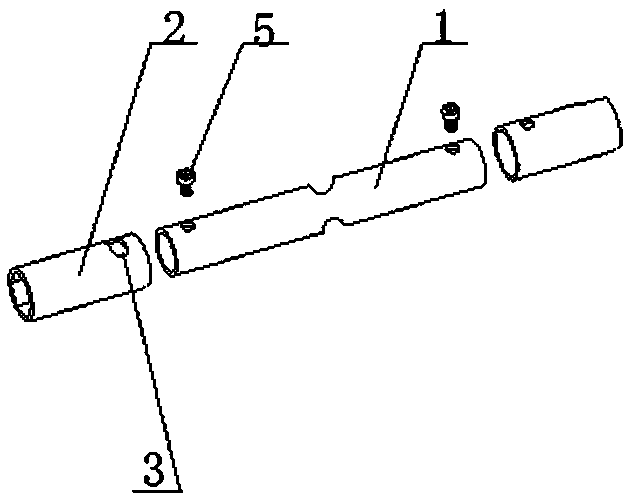

[0023] In the second embodiment of the wrench of the present invention, the difference between this embodiment and the above-mentioned specific embodiment 1 of the wrench is only: the threaded fastener in this embodiment is a fastener bolt or other detachable threaded fastener, Connect the inserted clamping piece and the main rod through the long hole.

specific Embodiment 3

[0024] In the third embodiment of the wrench of the present invention, the difference between this embodiment and the above-mentioned specific embodiment 1 of the wrench is only that: the hole in this embodiment is a square hole, and the square hole is in the circumferential direction around the main rod The size is larger than the radial size of the mating part of the threaded fastener.

[0025] In the fourth embodiment of the wrench of the present invention, the difference between this embodiment and the above-mentioned specific embodiment 1 of the wrench is only that: the length of the elongated hole located on the retaining member in this embodiment is equal to six of the circumference of the retaining member. One part or other dimensions that are larger than one-twelfth of the circumference of the holder and smaller than one.

specific Embodiment 5

[0026] In the fifth embodiment of the wrench of the present invention, the difference between this embodiment and the first embodiment of the above wrench is only that: the length of the elongated hole at the end of the main rod in this embodiment is equal to the circumference of the end of the main rod One-sixth or less than one-sixth of the circumference of the main rod end.

[0027] In the sixth embodiment of the wrench of the present invention, the difference between this embodiment and the first embodiment of the above wrench is only that: the elongated hole in this embodiment is located on the clamping member, and the width of the elongated hole is fixed Double or 2.5 times the screw diameter or other size larger than the diameter of the set screw.

[0028] In the seventh embodiment of the wrench of the present invention, the difference between this embodiment and the above-mentioned specific embodiment 1 of the wrench is only that: the elongated hole in this embodiment is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com