Product unique code full-automatic packaging production line

A fully automatic packaging and production line technology, applied in packaging, packaging machines, packaging protection, etc., to facilitate product information traceability and product quality supervision, reduce negligence, facilitate traceability and information supervision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

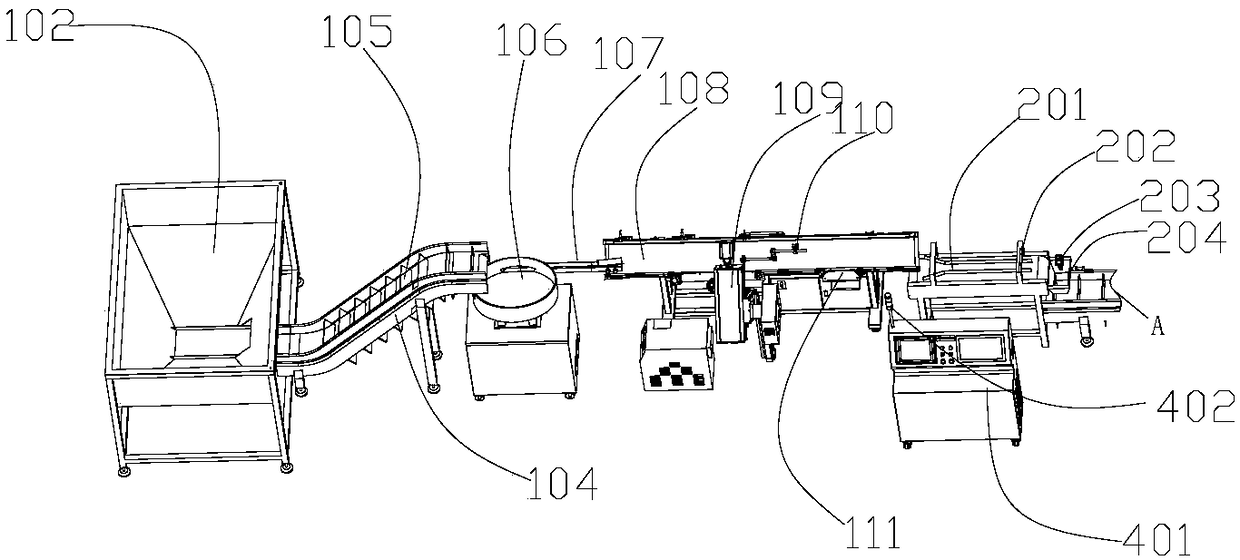

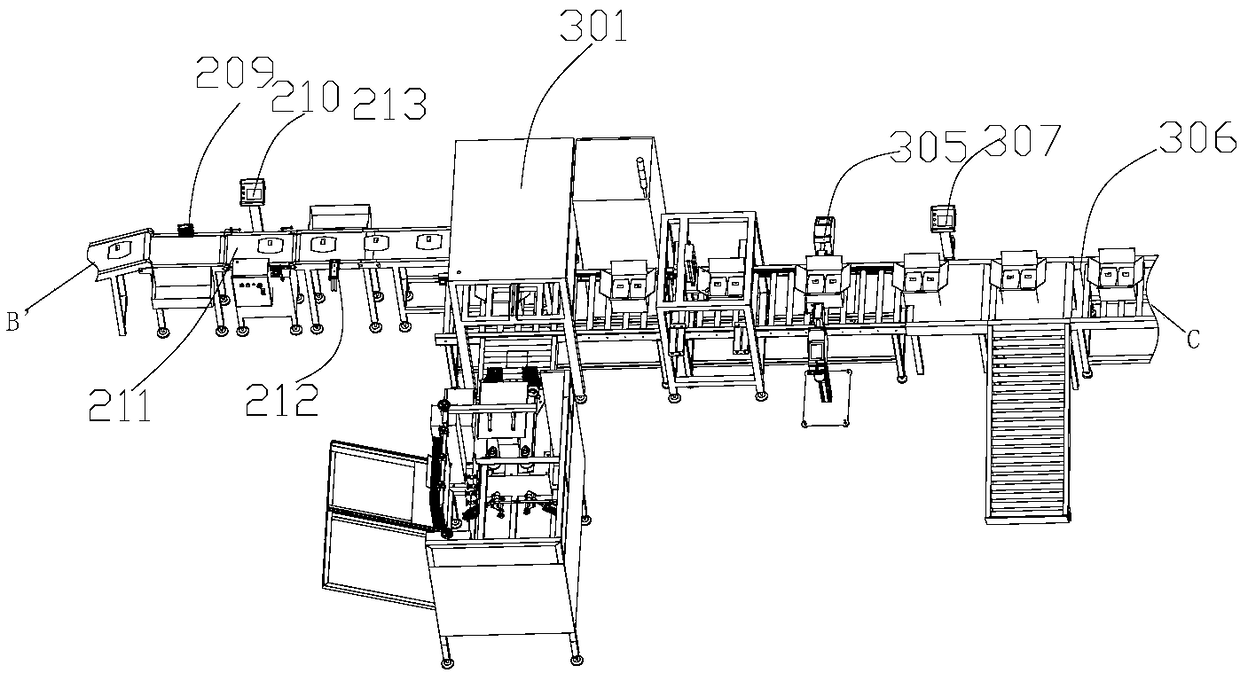

[0044] This embodiment provides a fully automatic packaging production line for uniquely coded products, such as figure 1 As shown in -4, it includes: product coding mechanism, bagging coding mechanism, boxing coding mechanism;

[0045] The product coding mechanism includes a loading sorting device and a laser machine coding device; the loading sorting device includes a lower hopper 102, a feeding conveyor belt 104, and a sorting device. The front end of the feeding conveyor belt 104 is adjacent to the lower opening of the lower hopper 102, The tail end of the feeding conveyor belt 104 is located above the sorting device, and the feeding conveyor belt 104 is provided with several partitions 105; the laser coding device includes a laser coding conveyor belt 108, a laser marking machine 109, a laser coding conveyor belt 108 and a sorting The exit of the device is adjacent, and the laser marking machine 109 is fixedly arranged on the side of the laser coding conveyor belt 108, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com