Operating method of equipment airborne multistage airbag cooperative shock absorber

A technique of buffering device and working method, which is applied in the direction of launching device, transportation and packaging, aircraft parts, etc. It can solve the problems of slow outward exhaust speed, airbag explosion, and limited effective buffering stroke, so as to achieve enhanced buffering effect and good buffering Effect, the effect of increasing the effective buffer stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

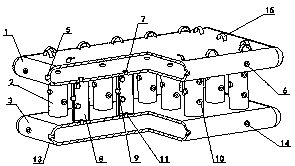

[0030] As shown in the figure: a working method equipped with an airborne multi-stage airbag cooperative buffer device, the multi-stage airbag cooperative buffer device includes an upper air bag 1, an air bag column 2 and a lower air bag 3; the present invention adopts an upper air bag 1, an air bag tube The column 2 and the lower airbag 3 are installed in a superimposed manner; the top of the upper airbag 1 is provided with a buckle device 15 to connect with the airborne equipment; the surface of the upper airbag 1 is provided with an upper airbag inflation valve 5, and the inside of the upper airbag 1 is the upper airbag chamber 4, and the upper airbag Ten upper airbag exhaust valves 6 are arranged on the surface of the upper airbag 1, and a joint exhaust valve 7 is arranged at the overlapping connection between the surface of the upper airbag 1 and the surface of each airbag column 2.

[0031] As shown in the figure: there are 12 airbag columns, and the airbag columns 2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com