Manufacture method of curved surface film photovoltaic building surface and adopted surface module

A technology of thin-film photovoltaics and manufacturing methods, applied in the field of construction, can solve the problems of complex 3D models, uncertain laws of sunlight collection, and lack of relatively mature technologies, etc., achieve good light transmission, reduce the difficulty of on-site installation, and maintain dimensional stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

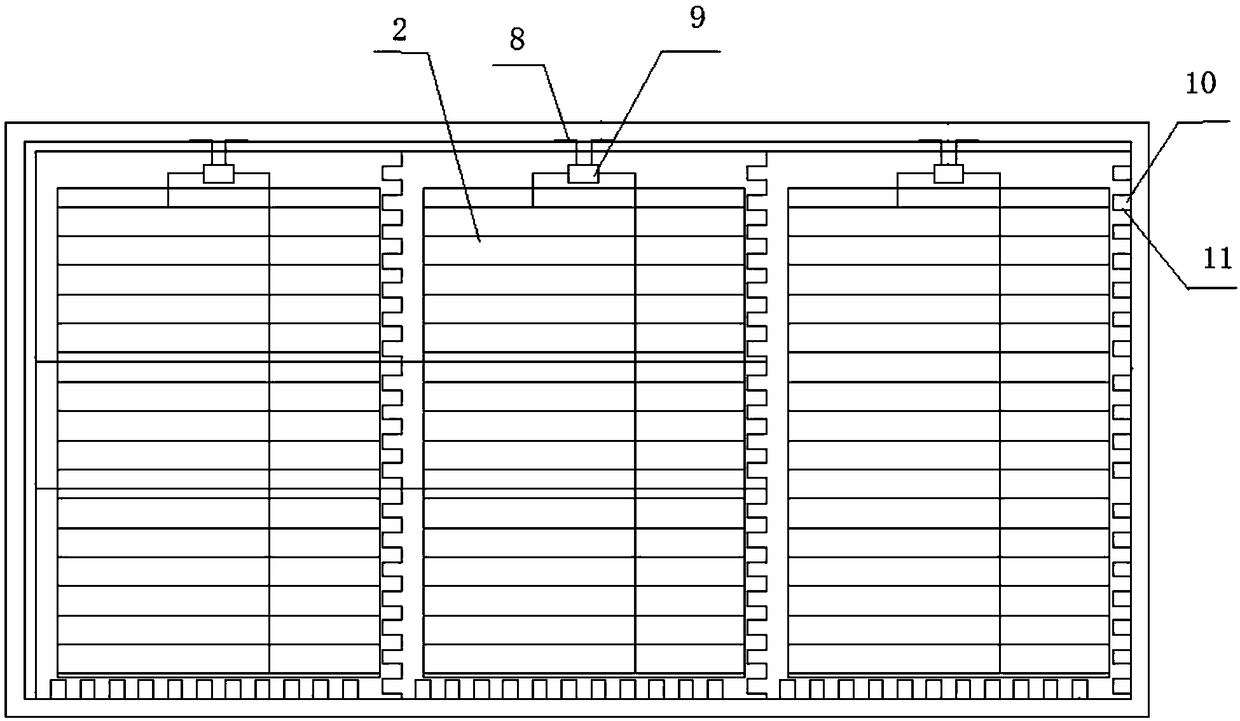

[0041] The schematic diagram of the connection structure between the skin module and the wall of the curved thin-film photovoltaic building of the present invention is shown in figure 1 , the manufacturing method of curved thin film photovoltaic building skin comprises the following steps:

[0042] (1) The architect designs the initial surface model according to the design concept of the design unit;

[0043] (2) Optimize the design with the goal of maximizing the solar radiation absorption, and obtain the optimized surface model;

[0044] (3) Divide the optimized surface model into multiple modules;

[0045] (4) According to the divided module graphics, use 3D printing technology to print out the rigid curved backplane, and sequentially stack and fix the first flexible laminated film, flexible thin-film solar cell, and second flexible lami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com