Integrated foundation pile static load test counterforce beam

A static load test and reaction beam technology, applied in the test of basic structure, basic structure engineering, construction, etc., can solve the problems of reducing equipment use efficiency, increasing verification cost, etc., to improve use efficiency, convenient installation and maintenance, The effect of low overall aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings in the embodiments of the present invention.

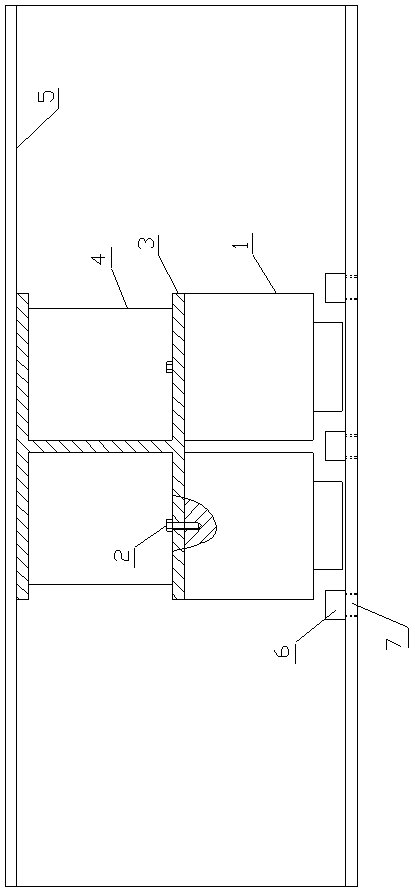

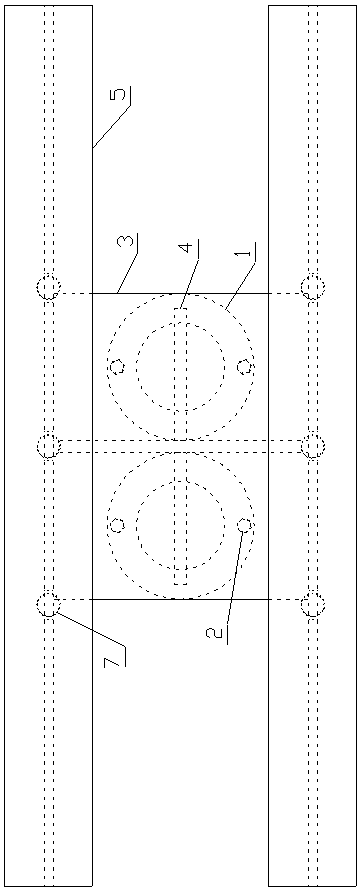

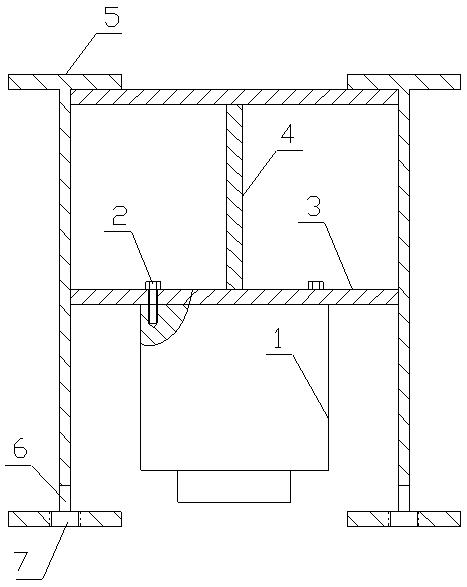

[0020] Such as Figure 1~3 As shown, an integrated pile foundation static load test reaction beam, the reaction beam includes a beam body, the beam body is provided with a bolt hole for connecting with the hydraulic jack 1, and the beam body is also provided with a The thread hole 7 and the process notch 6 matched by the column assembly used for the in-situ verification of the jack; the reaction beam also includes a hydraulic jack 1 and a jack connecting bolt 2 .

[0021] Such as Figure 1~3 As shown, the beam body includes two symmetrically arranged long beams 5 and component beams 3; the bottom of the two symmetrically arranged long beams 5 is provided with a Silk holes 7, and corresponding process gaps 6 are opened at the corresponding positions of the web plate and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com