Continuous wing fin bag sand barrier laying machine

A laying machine and wing fin technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of small area sand prevention design not reaching the effect, high labor intensity, and reduce labor intensity, so as to improve wind erosion effect, reduce labor intensity, and improve laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to illustrate the present invention more clearly, the present invention will be further described below with reference to the preferred embodiments and accompanying drawings. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

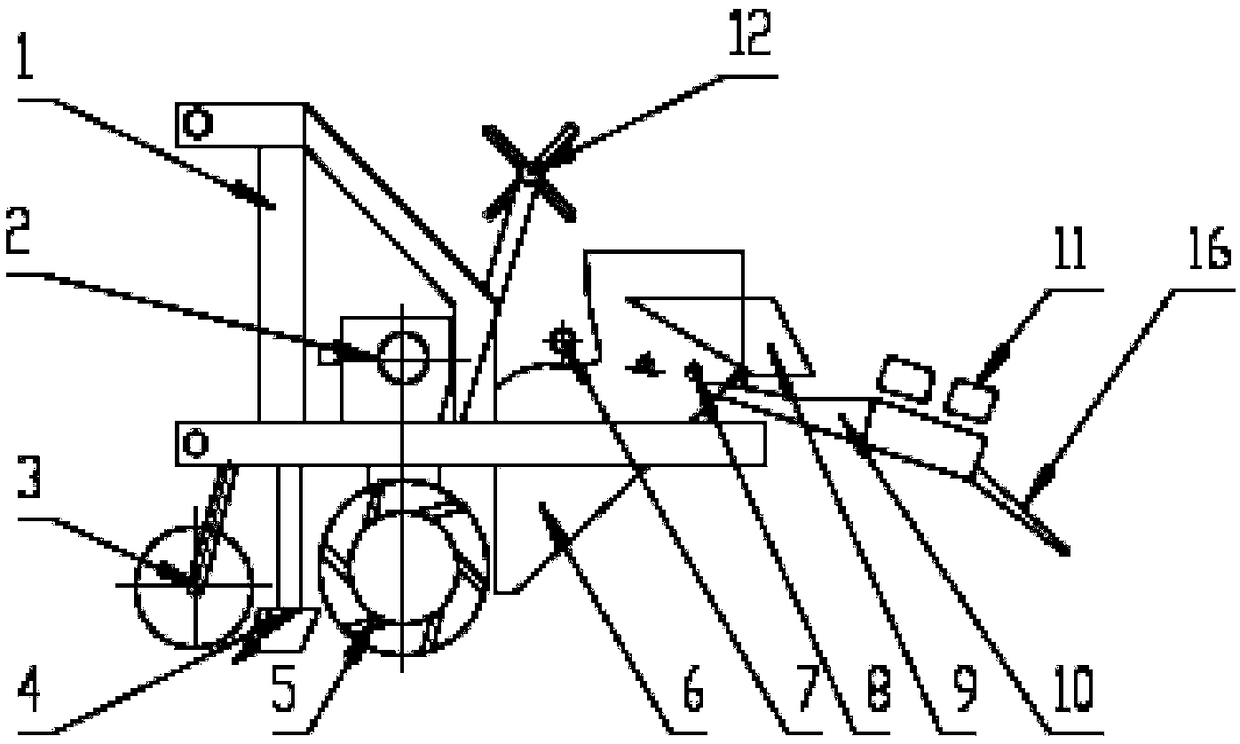

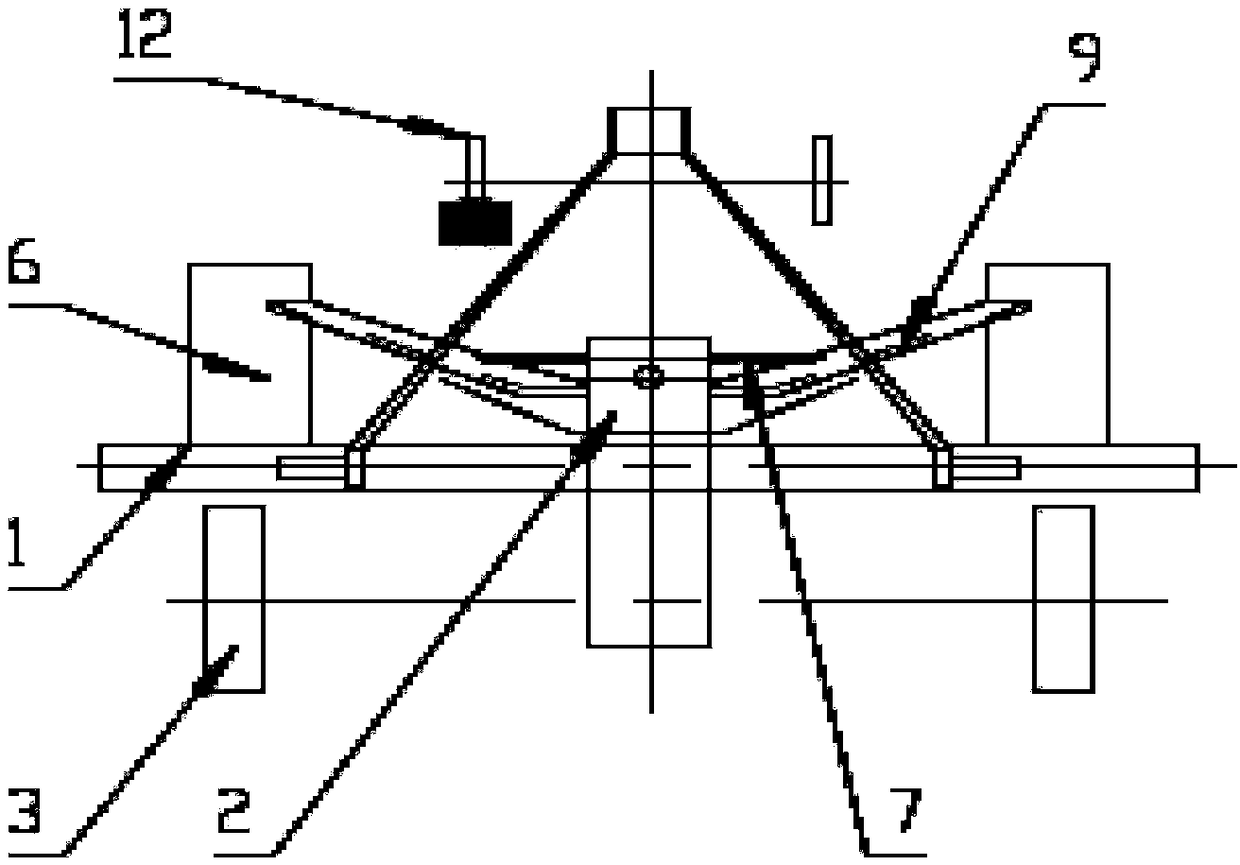

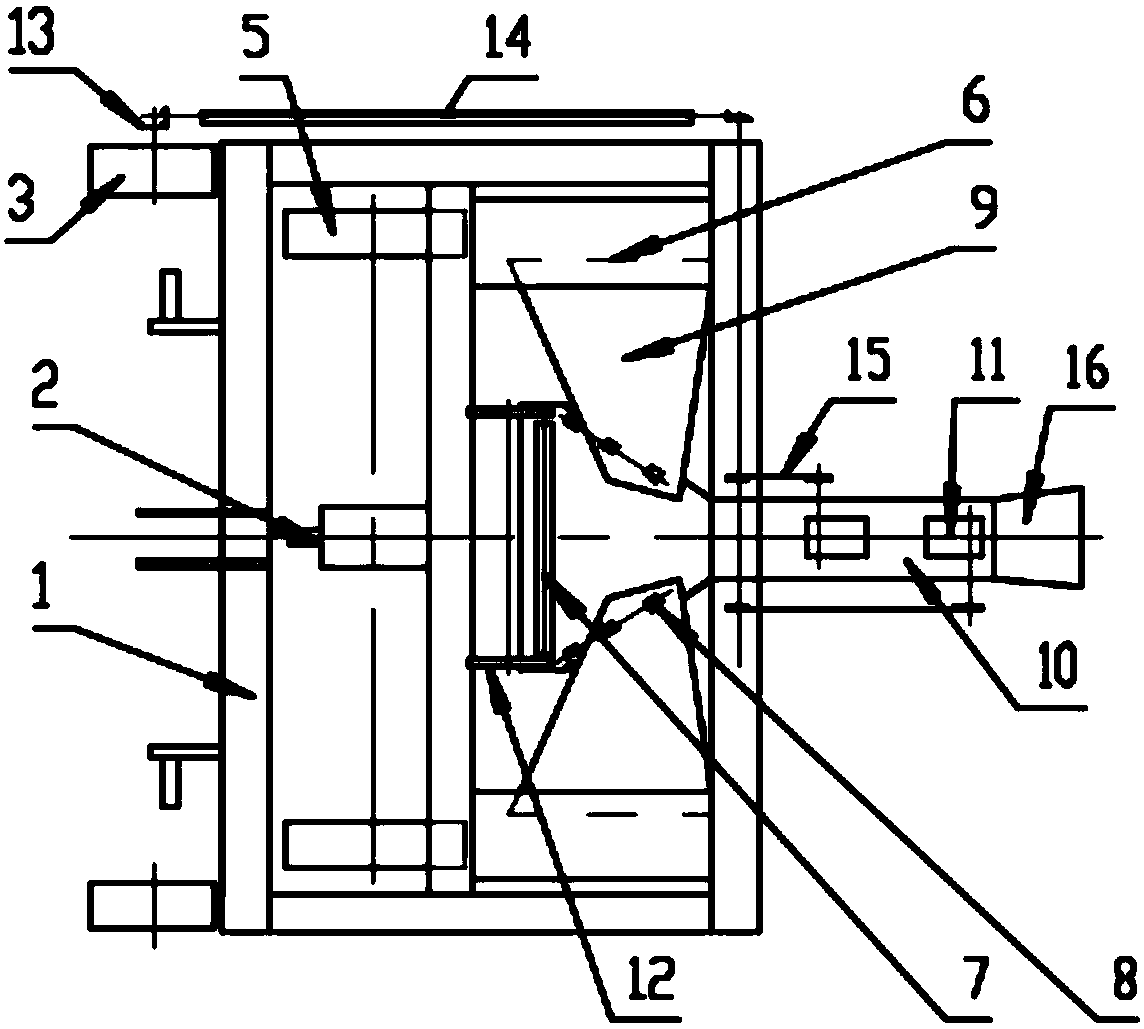

[0026] In one embodiment of the invention, as figure 1 and figure 2 As shown, a continuous wing-fin bag sand barrier laying machine includes a frame 1 and a sand barrier laying system arranged on the frame 1; the sand barrier laying system includes a sand barrier for collecting sand and placing the collected sand. The sand taking unit on the sand cloth, the bag making unit that sews the sand cloth with sand to form the fin bag, the filling unit that fills the fin bag with sand during the bag making process of the bag making unit Sand unit, and a laying unit that realizes continuous laying o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com