A sand-free fracturing fluid with high conductivity, its preparation method, fracturing technology and application

A conductivity and fracturing fluid technology, applied in the field of hydraulic fracturing, can solve the problems of increasing the difficulty of fracturing construction, fracturing failure, and inability to suspend proppant, shortening the fracturing construction period, reducing fracturing costs, The effect of reducing construction risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A kind of sandless fracturing fluid, comprising A group fracturing fluid and B group fracturing fluid, said A group fracturing fluid is made by adding epoxy resin prepolymer to guar gum fracturing fluid, said B group fracturing fluid The fracturing fluid is prepared by adding water-based polyurethane curing agent and modified glass fiber to the guar gum fracturing fluid.

[0050] The above-mentioned preparation method of the sand-free fracturing fluid with high conductivity comprises the following steps:

[0051] (1) Preparation of group A fracturing fluid

[0052] Disperse 80g of epoxy resin prepolymer in 100g of guar gum fracturing fluid to obtain Group A fracturing fluid;

[0053] (2) Preparation of Group B fracturing fluid

[0054] Disperse 24g of water-based polyurethane curing agent, 0.32g of glass fiber with a length of 10mm, and 3g of nano-titanium dioxide in 100g of guar gum fracturing fluid to obtain group B fracturing fluid.

[0055] The mass ratio of the ...

Embodiment 2-6

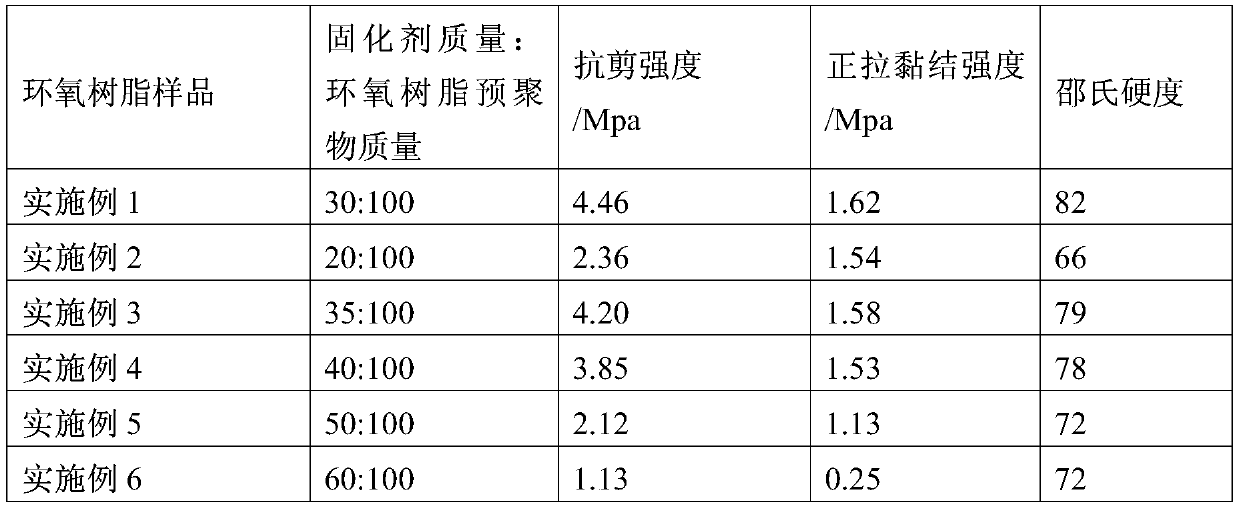

[0061] As described in Example 1, the difference from Example 1 is:

[0062] The mass ratios of the water-based polyurethane curing agent in the fracturing fluid of Group B to the epoxy resin prepolymer in the fracturing fluid of Group A are 20:100, 35:100, 40:100, 50:100, and 60:100, respectively.

Embodiment 7-10

[0064] As described in Example 1, the difference from Example 1 is:

[0065] Nano titanium dioxide is not added to the fracturing fluid of group B, that is, the glass fiber is unmodified glass fiber, and the length of the glass fiber is 8mm;

[0066] The mass ratios of the unmodified glass fiber to the epoxy resin prepolymer in group A fracturing fluid are 0.2:100, 0.3:100, 0.4:100, and 0.5:100, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com