On-board weighing method for measuring freight train based on bolster

A vehicle-mounted weighing method and freight train technology, applied in the field of freight train vehicle-mounted weighing, can solve problems such as inability to detect the center of mass, affect work efficiency, and economic losses, and achieve the effects of low cost, high precision, and a wide range of applicable models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

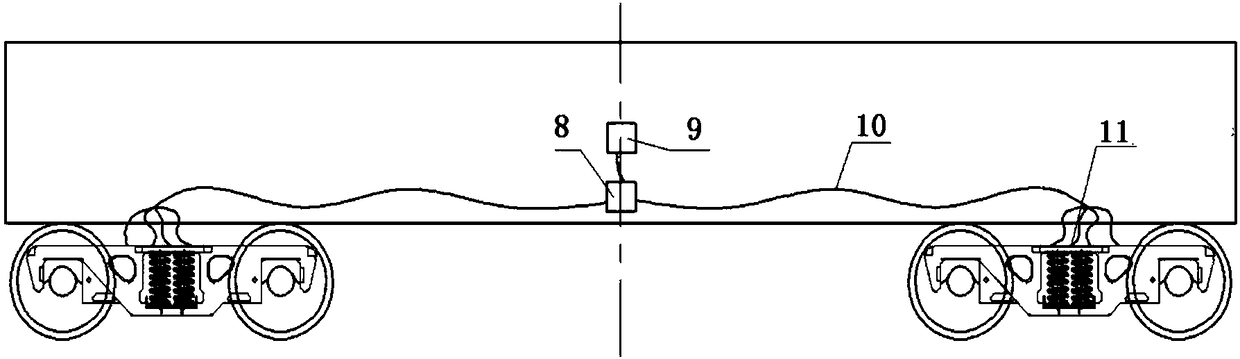

[0012] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

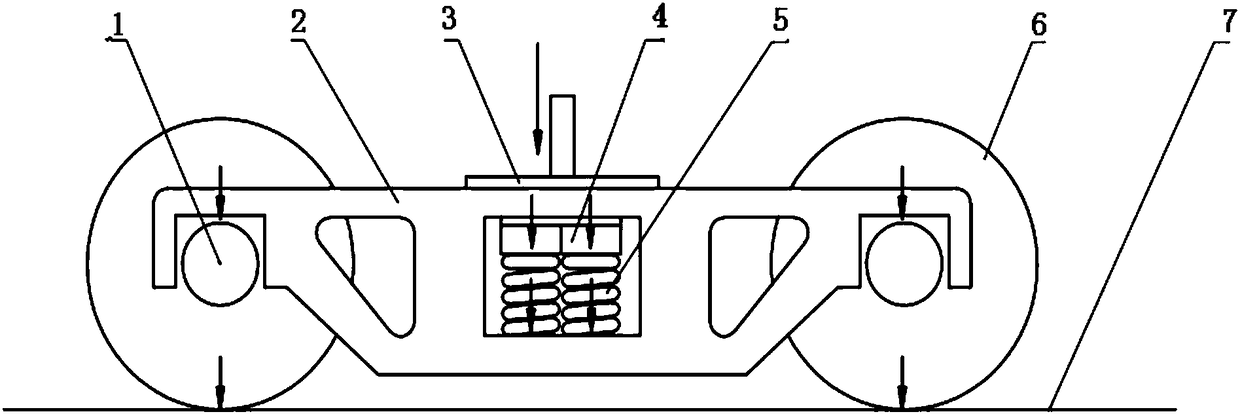

[0013] From figure 1 It can be seen that the weight transfer order of the freight train after loading cargo is that the car sits on the lower center plate 3 of the bogie, the center plate 3 transmits the force to the bolster 4, and the bolster 4 transmits the force to the side frame 2 through the spring 5 , the side frame 2 then transmits the force to the axle 6 through the bearing 1, and finally acts on the rail 7. Among them, the bolster 4 is an independent load-bearing component, and there is no possibility of missing force, so the on-board weighing can be realized by indirectly measuring the deformation information of the bolster.

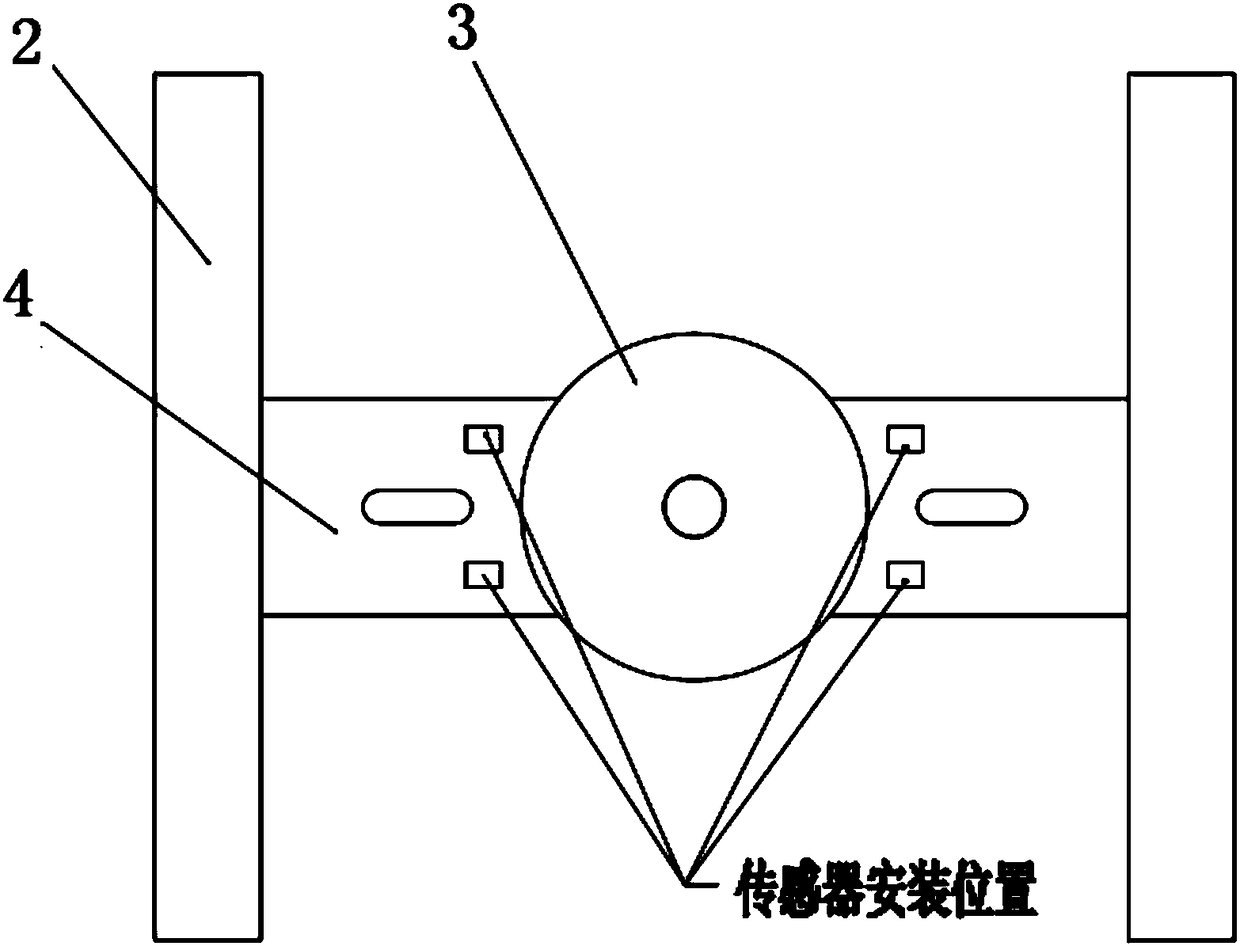

[0014] After modeling and simulation analysis, the stress output at the upper surface between the center plate of the bolster and the side bearing is larger and the linearity is better, so the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com