A container classification and inspection method based on data acquisition and analysis

A data acquisition and container technology, applied in the field of container classification and inspection based on data acquisition and analysis, can solve problems such as difficult work, error-prone data, and high labor intensity, so as to reduce work intensity, improve work efficiency, and reduce management cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

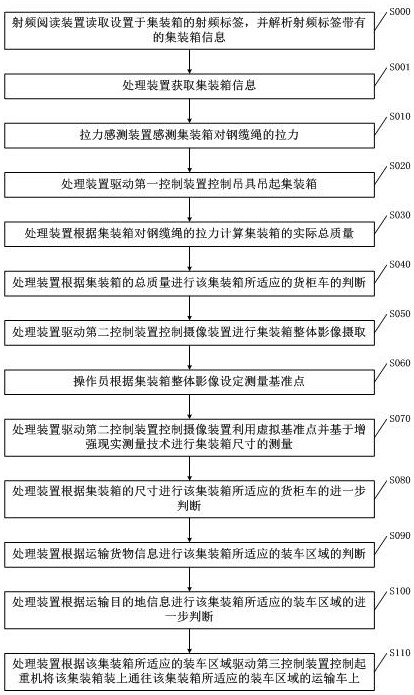

[0045] The reference picture is figure 1 . A method for container classification and inspection based on data acquisition and analysis, said method comprising the following steps:

[0046] S010: The processing device drives the first control device to control the spreader to lift the container;

[0047] S020: the tension sensing device senses the tension of the container on the steel cable;

[0048] S030: The processing device calculates the actual total mass of the container according to the pulling force of the container on the steel cable;

[0049] S040: The processing device judges the container truck suitable for the container according to the total mass of the container;

[0050] S050: The processing device drives the second control device to control the camera device to capture the overall image of the container;

[0051] S060: The operator sets the measurement reference point according to the overall image of the container;

[0052] S070: The processing device dri...

Embodiment 2

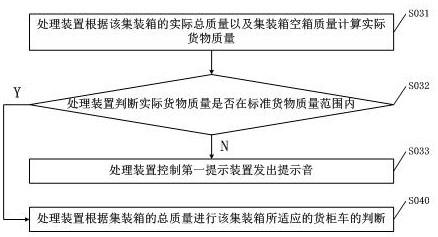

[0064] The reference picture is figure 2 , image 3 . With regard to Embodiment 1, the difference of this embodiment lies in:

[0065] As a preferred mode of the present invention, the step S030 also includes the following steps:

[0066] S031: The processing device calculates the actual cargo mass according to the actual total mass of the container and the empty container mass;

[0067] S032: The processing device compares and judges the actual cargo quality with the standard cargo quality, and if it judges that the actual cargo quality is within the standard cargo quality range, execute step S040; if it judges that the actual cargo quality is not within the standard cargo quality range, execute step S033;

[0068] S033: The processing device controls the first prompting device to emit a prompt sound.

[0069] As a preferred mode of the present invention, the step S070 also includes the following steps:

[0070] S071: The processing device compares and judges the measur...

Embodiment 3

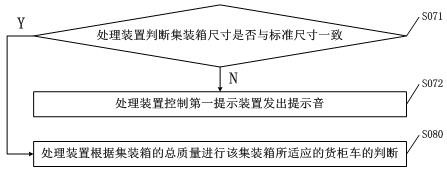

[0074] The reference picture is Figure 4 . With regard to Embodiment 1, the difference of this embodiment lies in:

[0075] As a preferred mode of the present invention, the step S090 also includes the following steps:

[0076] S091: The processing device limits the transportation lane according to the judgment of the loading area that the container is suitable for.

[0077] As a preferred mode of the present invention, the step S100 also includes the following steps:

[0078] S101: The processing device further defines the transport lane according to the further judgment of the loading area that the container is suitable for.

[0079] In the specific implementation process, in the device corresponding to the method, several transport cargo lanes are set according to the comparison and judgment benchmark in the content of the above-mentioned judgment method. In the first embodiment, the cargo lanes are defined according to the container-adapted loading area judged by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com