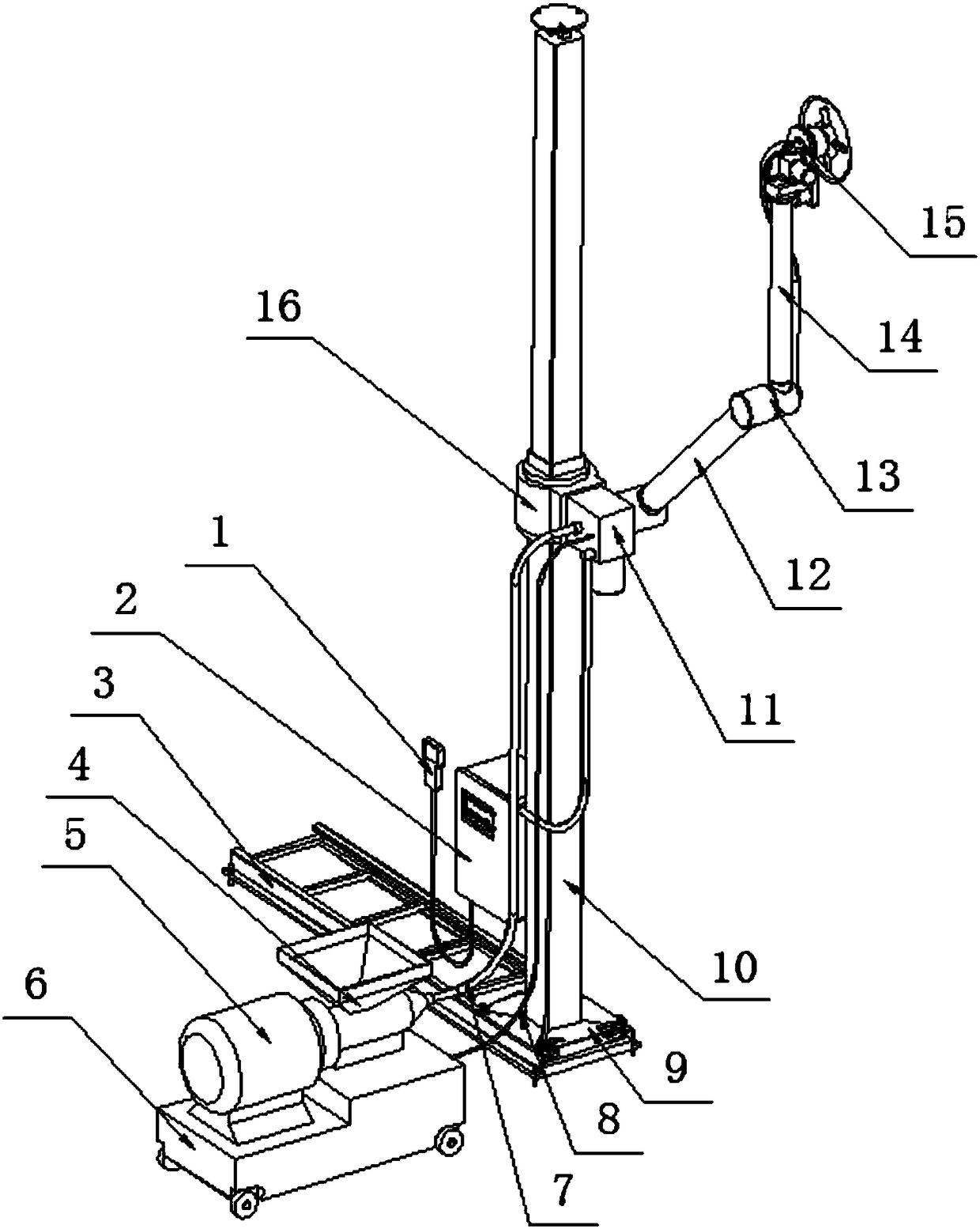

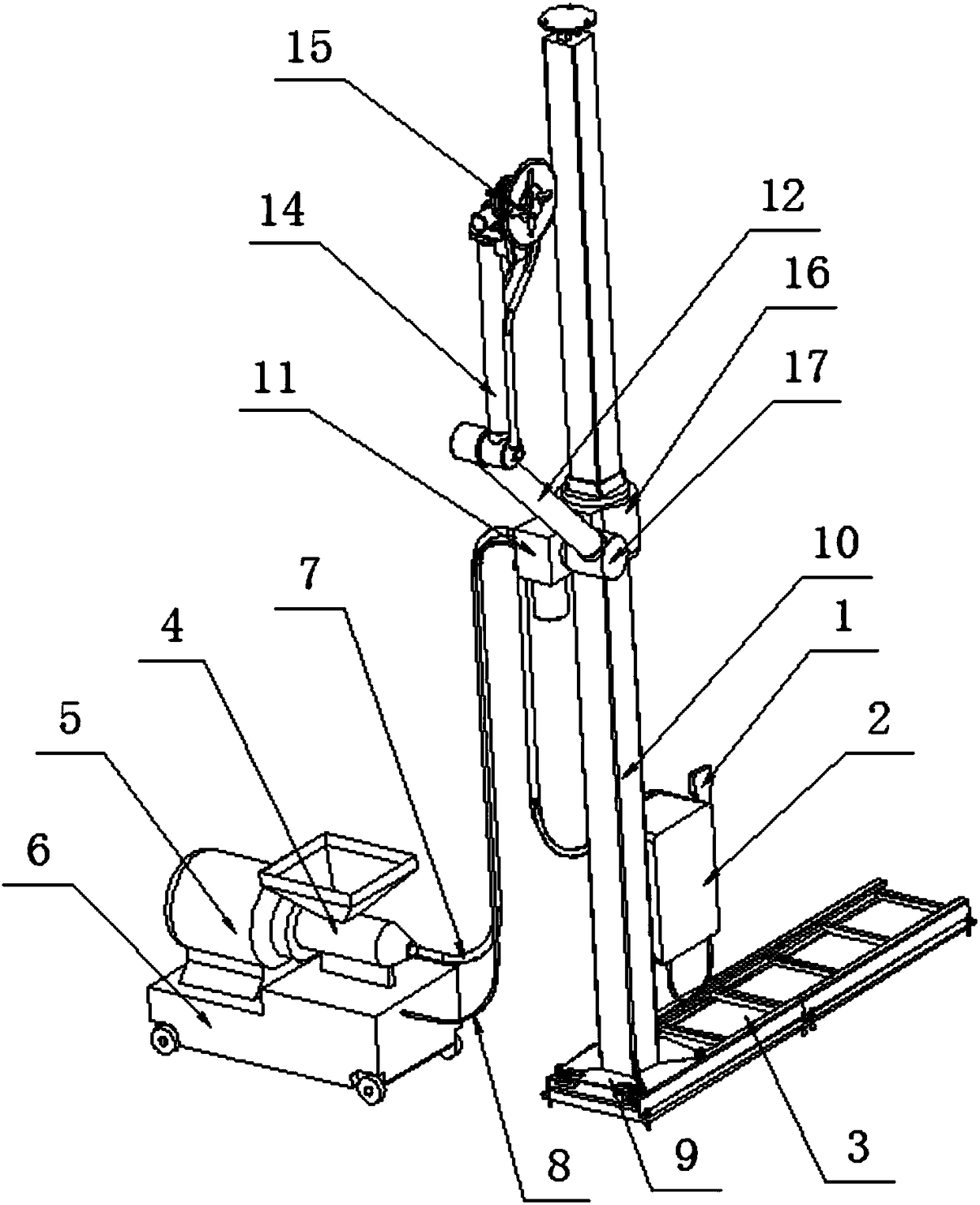

Automatic painting mechanical arm

A manipulator and automatic technology, applied in the direction of construction, building structure, etc., can solve the problems of high cost of manual painting, quality problems of painting, and inability to guarantee the completion time of the construction period, so as to achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028] The specific implementation is as follows: in the process of use, through the control device, the power device is controlled to work, the power device respectively drives the joint block A13 and the joint block B17 to move, the joint block A13 drives the movable arm B14 to move, and the joint block B17 drives the movable arm A12 to move , through the linkage relationship between the movable arm A12 and the movable arm B14, a certain range of coverage is formed. During the covering process, the device can have a larger range of motion. When the power device is moving, the feeding pump 15 in the feeding device also starts to work. The vacuum pump 6 will also work at the same time. Through the mutual cooperation between the vacuum pump 6 and the feeding device, the spraying intensity can be increased. At the same time, the movement stroke of the movable arm A12 and the movable arm B14 can be combined to make this device achieve the purpose of painting. , while bringing conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com