Light composite wallboard forming mold

A composite wallboard and forming mold technology, applied in molds, mold trays, mold panels, etc., can solve problems such as low production efficiency, low utilization rate, and poor working conditions, and achieve high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

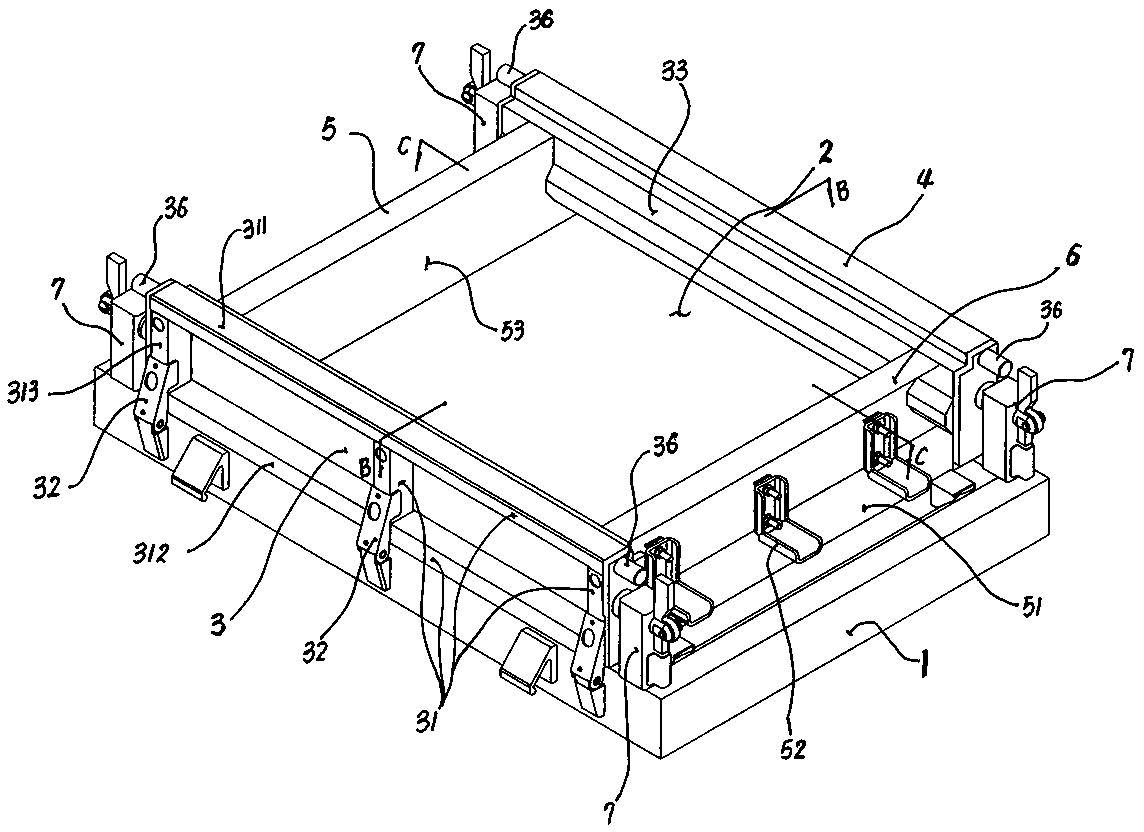

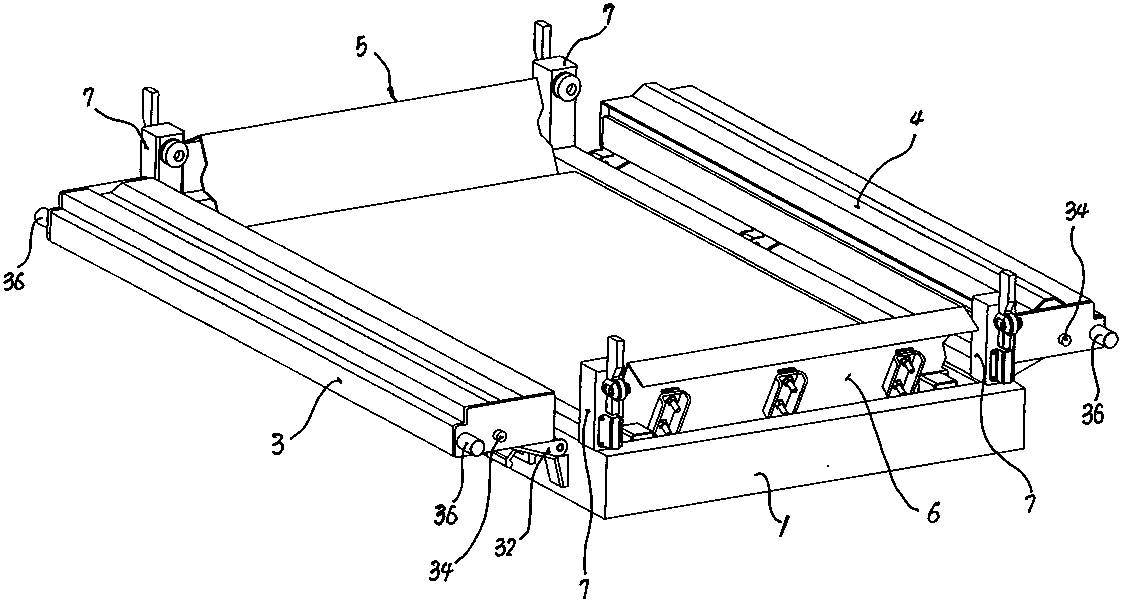

[0027] The light-duty composite wallboard forming mold of the present invention includes a base 1, a bottom formwork 2, a front formwork assembly 3, a rear formwork assembly 4, a left formwork assembly 5, and a right formwork assembly 6, which are respectively connected with the front formwork assembly. The left and right ends of 3 and the left and right ends of the rear formwork assembly 4 cooperate with the positioning locking device 7; the front formwork assembly 3 and the rear formwork assembly 4 have the same symmetrical structure, and the left formwork assembly 5 and the right The template assembly 6 has the same symmetrical structure.

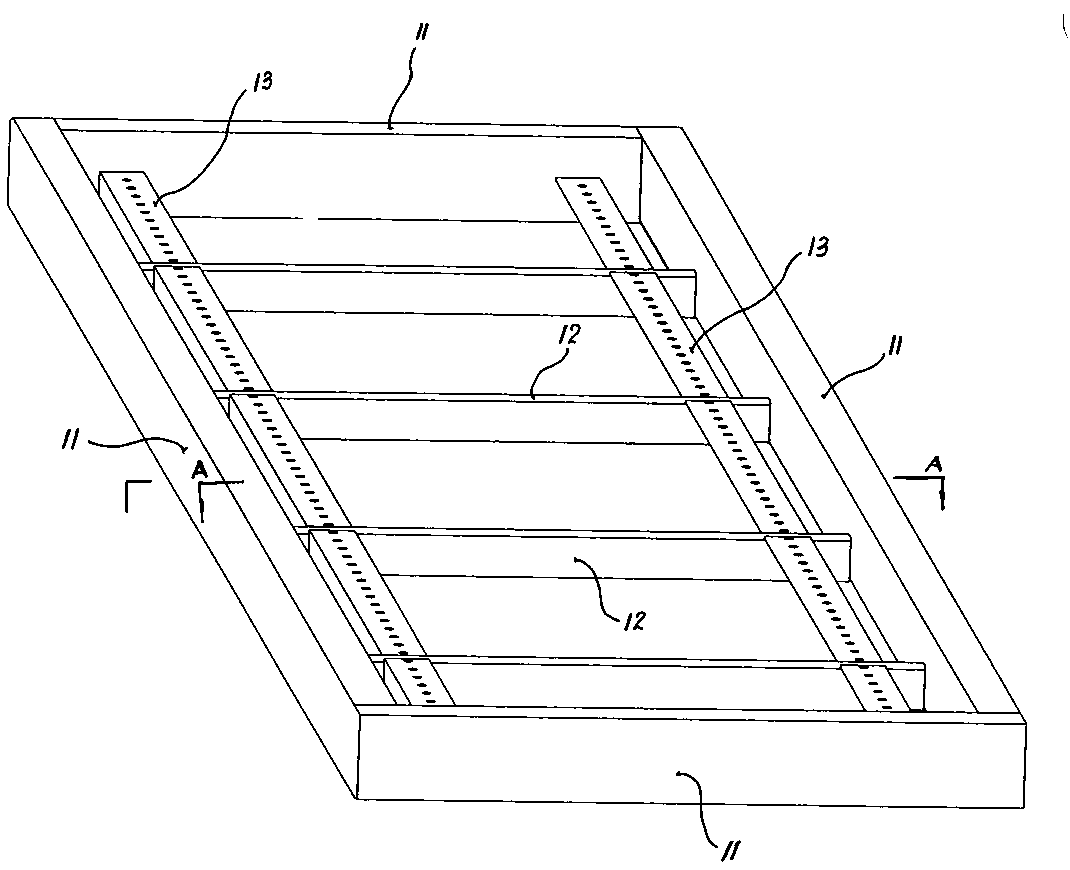

[0028] The base 1 includes four frames 11 , beams 12 and longitudinal beams 13 distributed and fixedly connected in the four frames 11 .

[0029] Bottom formwork 2 includes planar plate 21, four side beams 22 fixedly connected to the lower end surface of planar plate 21, and beams and longitudinal beams that are distributed and fixedly c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com