A method and system for simultaneously producing high-concentration boron-10 boron trifluoride and high-concentration boron-11 boron trifluoride

A boron trifluoride, high-concentration boron technology, applied in the direction of boron halide compounds, boron halides, etc., can solve the problems of large consumption of raw materials, increased product cost, unrealized industrial production, etc., to reduce production costs, energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

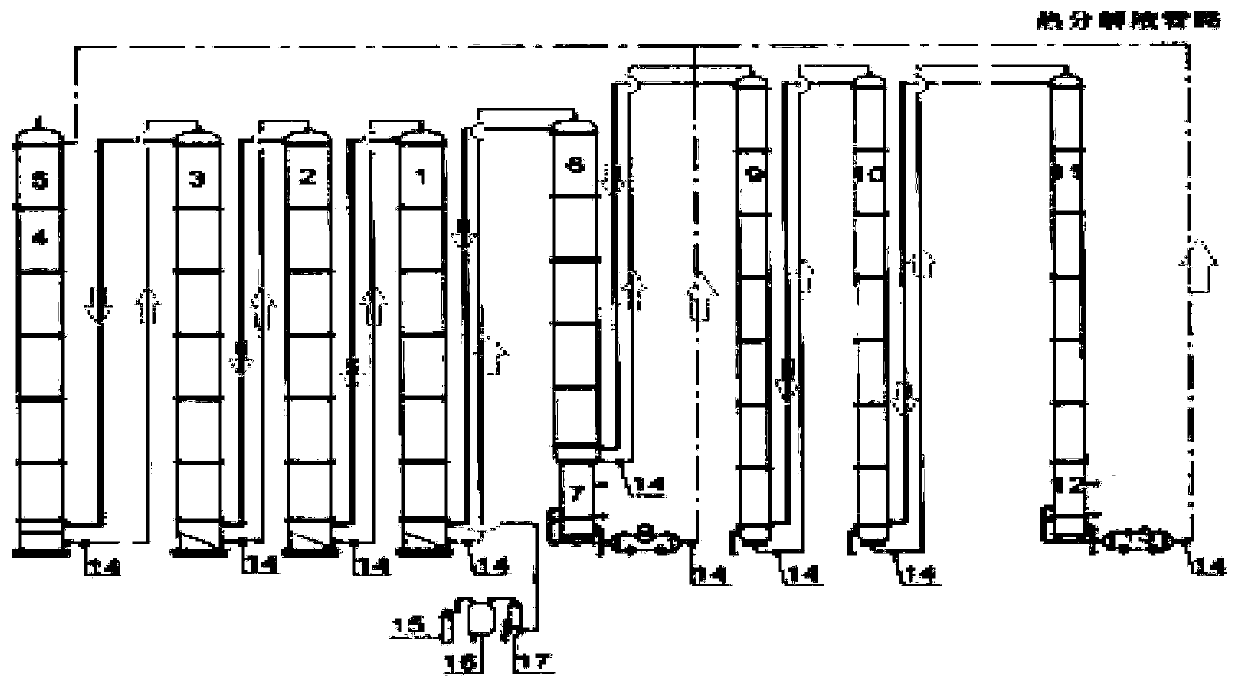

Image

Examples

Embodiment 1

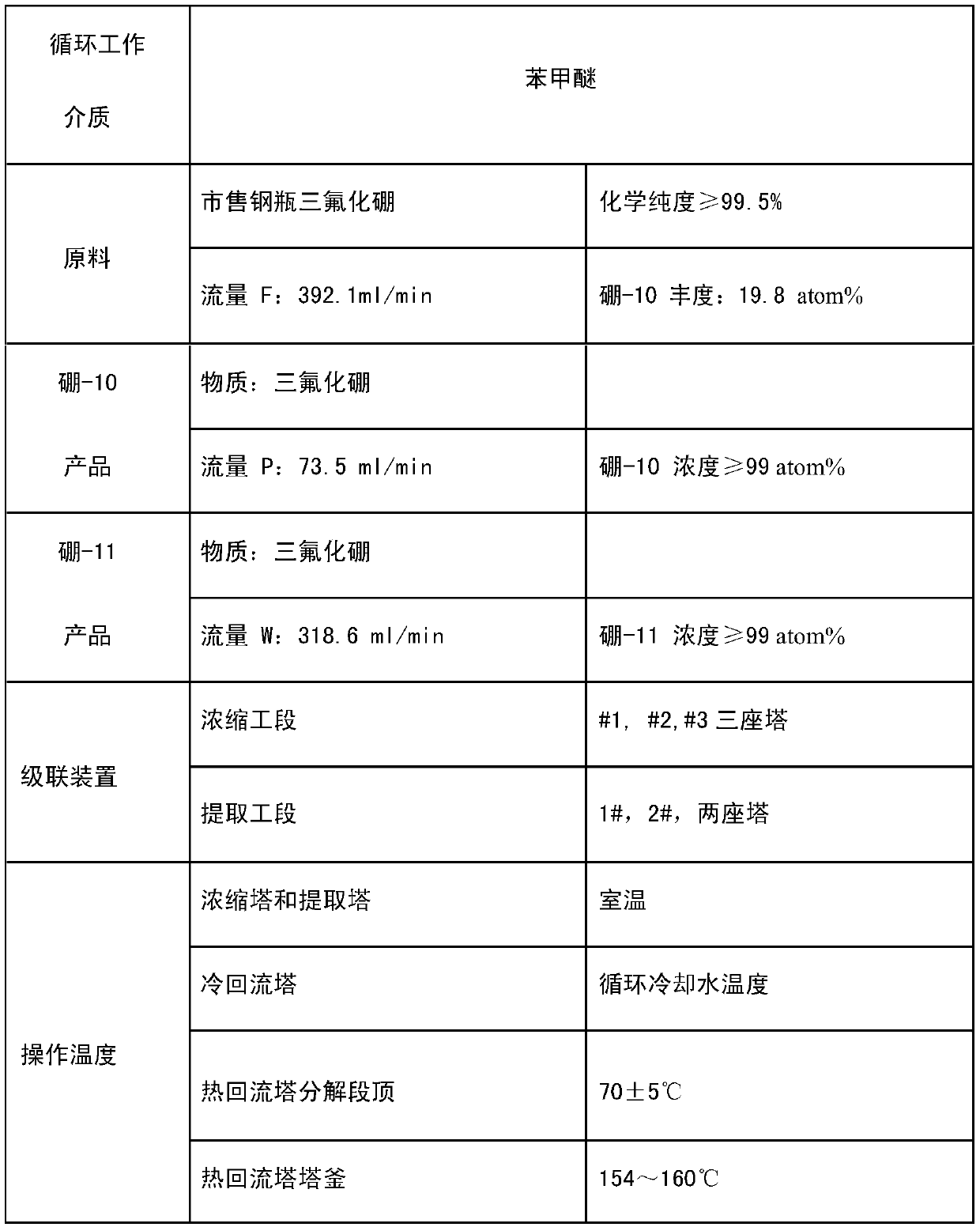

[0036] This embodiment adopts the working system of boron trifluoride / anisole, and the raw material boron trifluoride is boron trifluoride in a steel cylinder with a natural abundance of boron-10 of 19.8atom%. -10 boron trifluoride product flow rate is 73.5±0.5ml / min (about 17kg boron-10 / y), boron-11 boron trifluoride product flow rate is 318.6±0.5ml / min (about 83kg boron-11 / y).

[0037] In the present embodiment, there are 3 concentration towers in total to obtain an annual output of 17kg of net boron-10 (the boron-10 isotope concentration reaches 99atom%), and a total of 2 extraction towers to obtain an annual output of 83kg of net boron-11 (boron-11 The isotope concentration reaches 99atom%).

[0038] The extraction tower in the extraction section and the concentration tower in the concentration section are both countercurrent contact gas-liquid mass transfer towers.

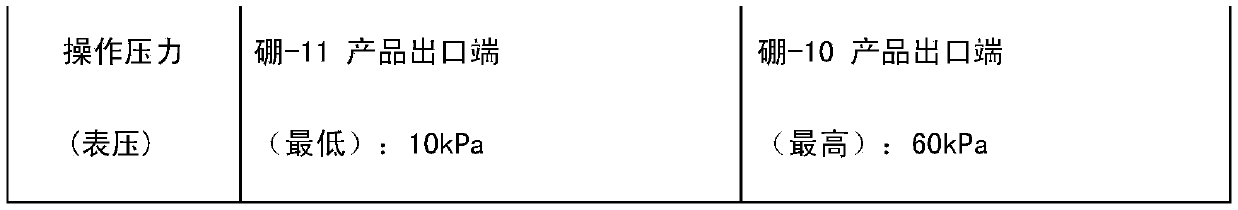

[0039] The operating temperature of the concentration tower is 20-30°C, the operating pressure is 0.02-0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com