Detection method of vacuum manipulator anti-collision detection system based on multi-dimensional vision sensor

A vacuum manipulator and visual sensor technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problem of high cost, achieve the effect of low cost and ensure effective working distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

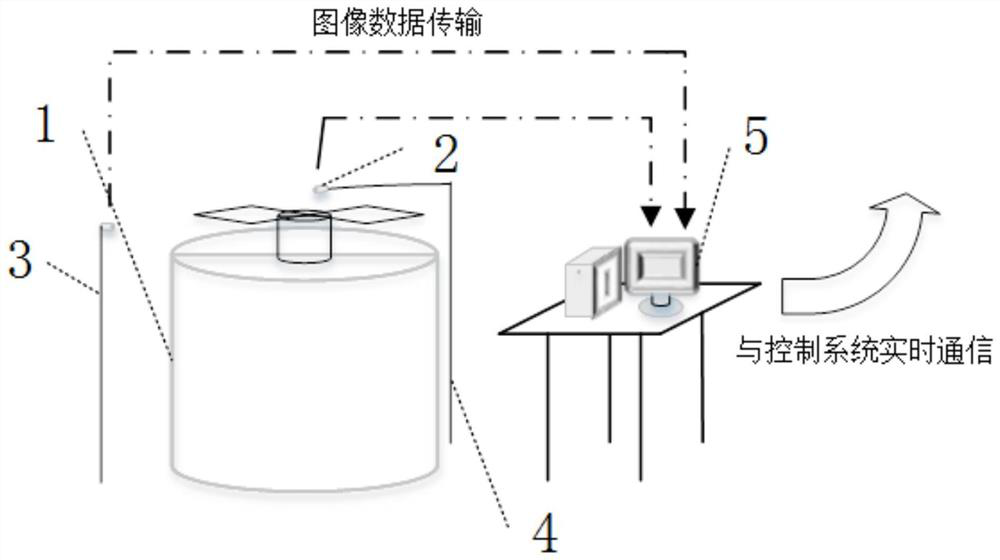

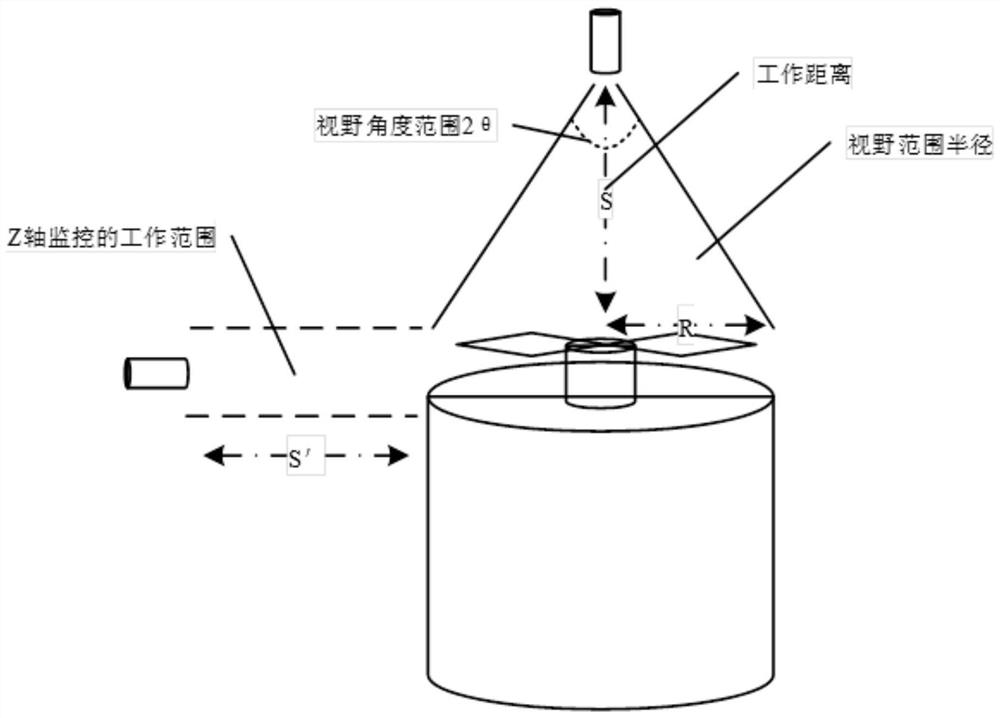

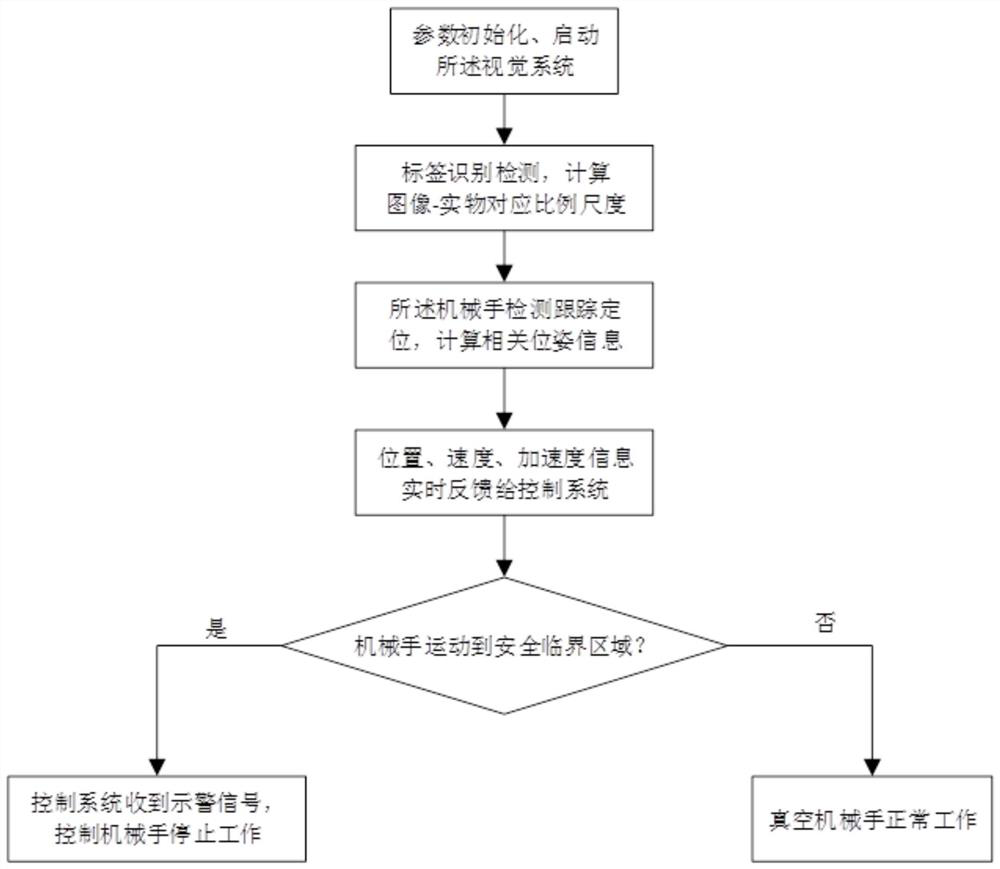

[0035] like Figure 1 to Figure 3 As shown, a vacuum manipulator anti-collision detection system based on multi-dimensional vision sensors includes: a vacuum manipulator equipment system 1 for normal work, carrying and transporting wafers; two sets of high-definition cameras, one of which is for x-y axis high-definition monitoring The camera 2 is installed directly above the worktable of the vacuum manipulator in the vacuum manipulator equipment system 1, and is used to detect changes in the position and attitude of the vacuum manipulator in the x-y axis horizontal plane; the other group is the z-axis high-definition monitoring camera 3, which The side of the vacuum manipulator is vertically placed to detect the position change in the direction of the telescopic axis of the vacuum manipulator; two sets of camera supporting brackets 4 are used to support and place the x-y axis high-definition monitoring camera 2 and the z-axis high-definition monitoring camera 3 respectively.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com