Rim end diameter runout detection device and rim end diameter runout detection equipment

A technology of runout detection and rim, which is applied to measuring devices, instruments, etc., can solve the problems of inaccurate runout data of rim end diameter and inaccurate rim runout data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

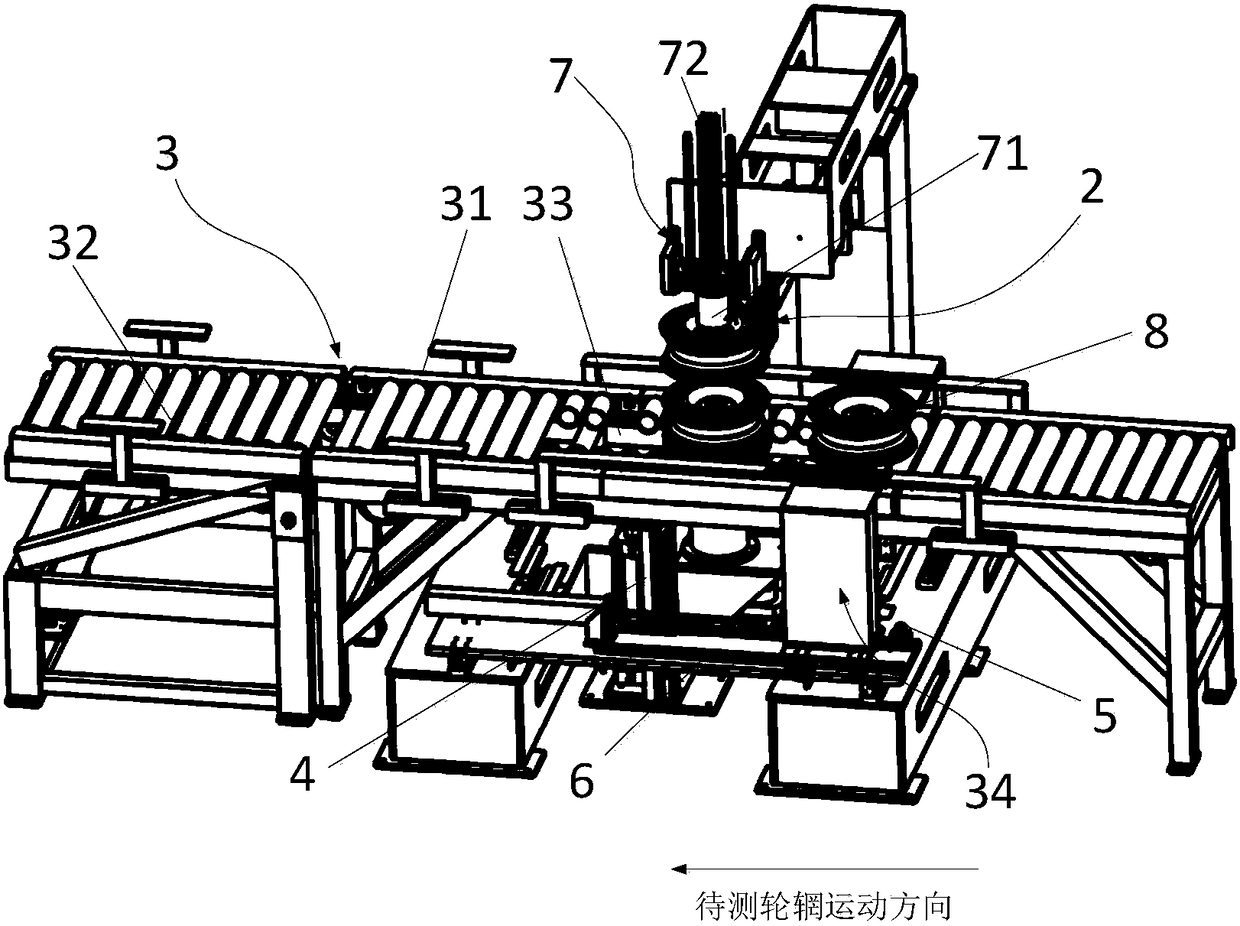

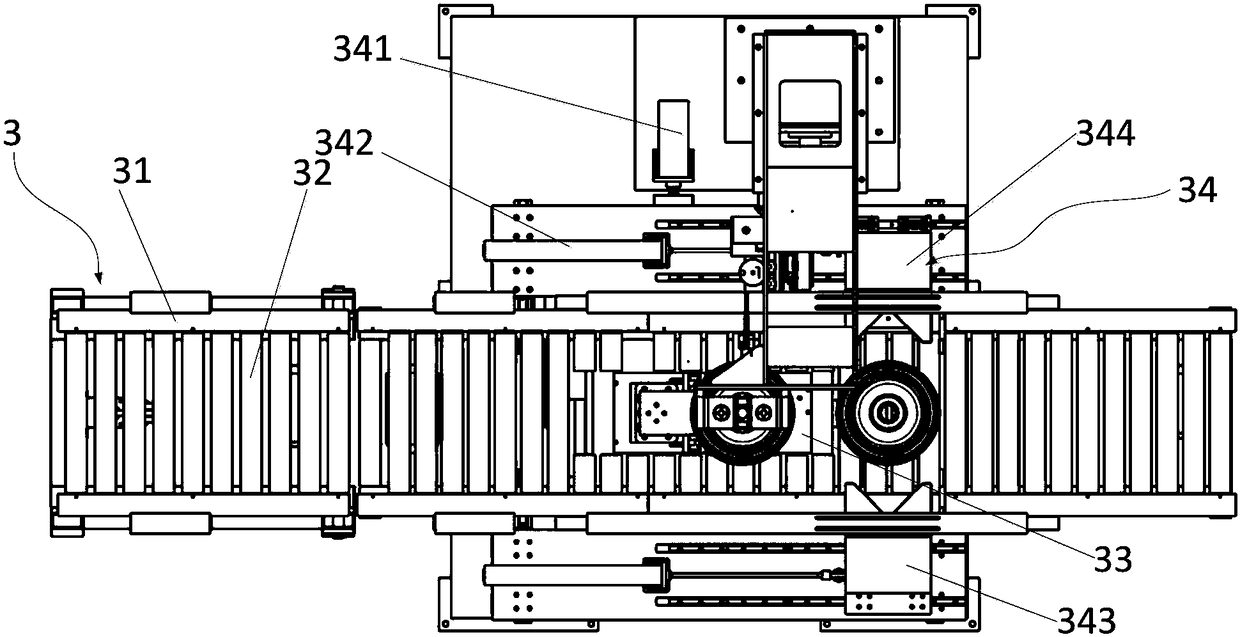

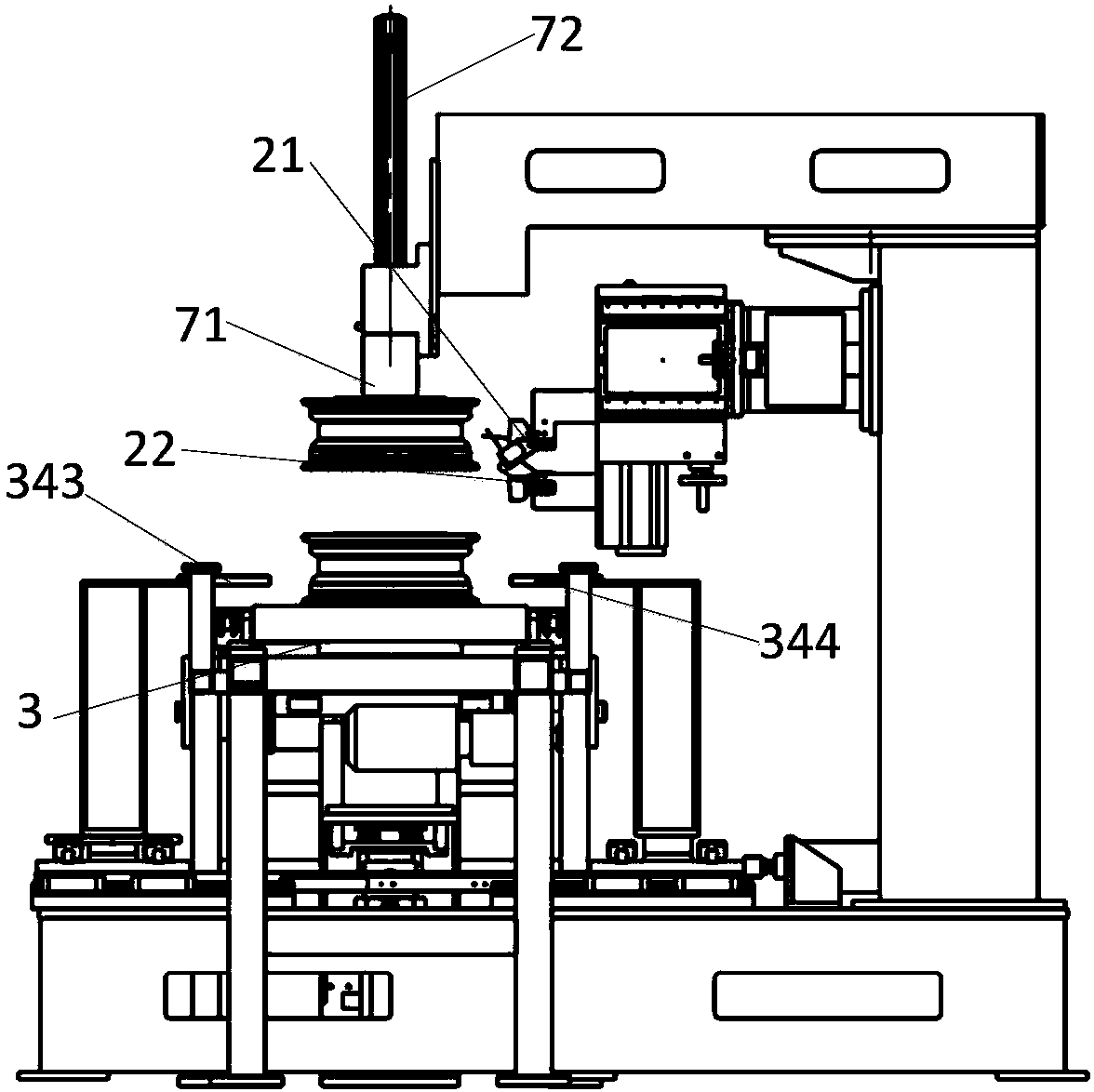

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6As shown, a rim end diameter runout detection device provided in this embodiment includes a rim fixing and clamping assembly 1 and a detection assembly 2 for detecting the runout state of the end diameter of the rim 8 to be tested. The rim fixing and clamping assembly 1 includes a A tensioning assembly 11 for fixing the rim 8 to be tested and a rotating assembly for driving the rim 8 to be tested to rotate.

[0039] The tensioning assembly 11 includes a locking sleeve 111 with a cavity structure, a tensioning member 112 located in the cavity structure of the locking sleeve 111 and a drive assembly 113 that drives the tensioning member 112 to move axially along the locking sleeve 111. When the tensioning member 112 moves to conflict with the locking sleeve 111, the locking sleeve 111 can be more closely attached to the inner wall of the rim 8 to be tested.

[0040] The rim end diameter run...

Embodiment 2

[0069] This embodiment provides a rim end diameter runout detection device, which has the rim end diameter runout detection device described in the first embodiment above.

[0070] The rim end diameter runout detection device has the same advantages as the above-mentioned rim end diameter runout detection device, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com