Fruit bagging machine and bagging method

A bagging machine and fruit technology, which is applied in the fields of botanical equipment and methods, plant protection cover, gardening, etc., can solve the problems of poor negative pressure adsorption effect, difficult sealing of fruit bags, and high equipment power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

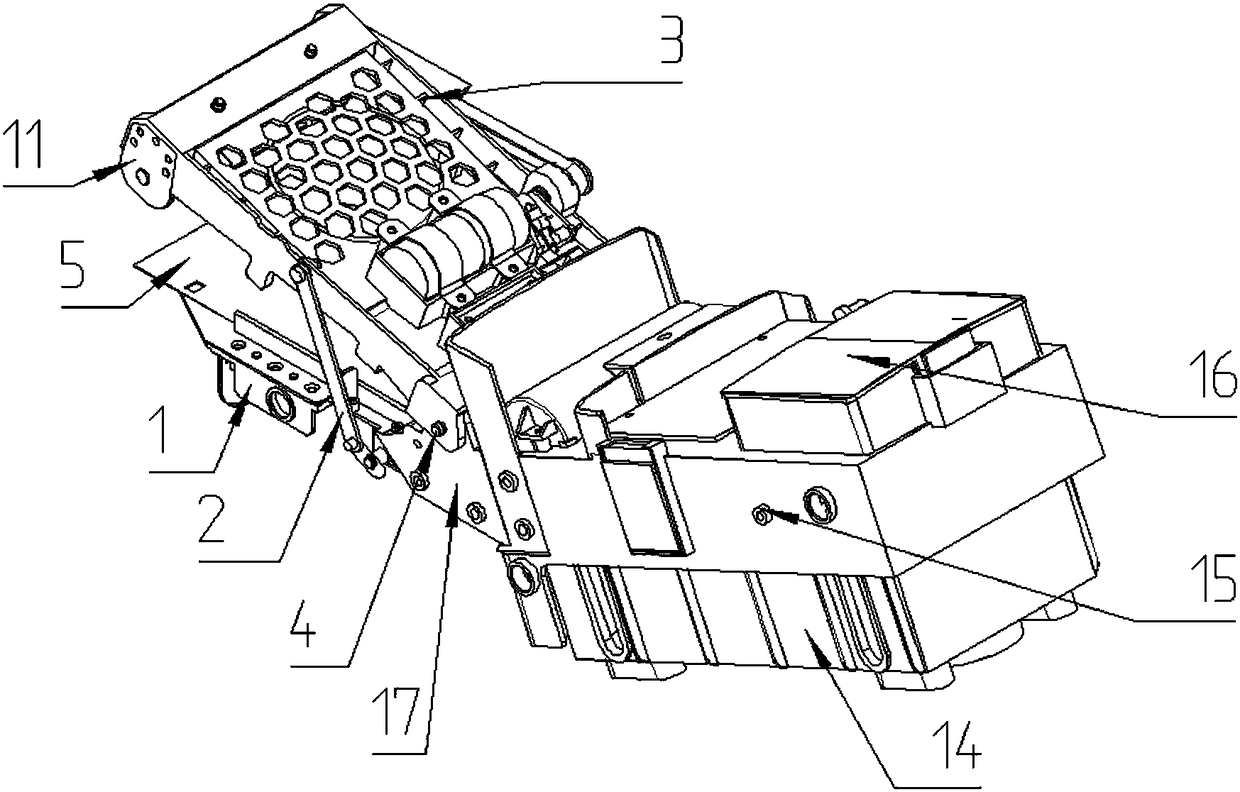

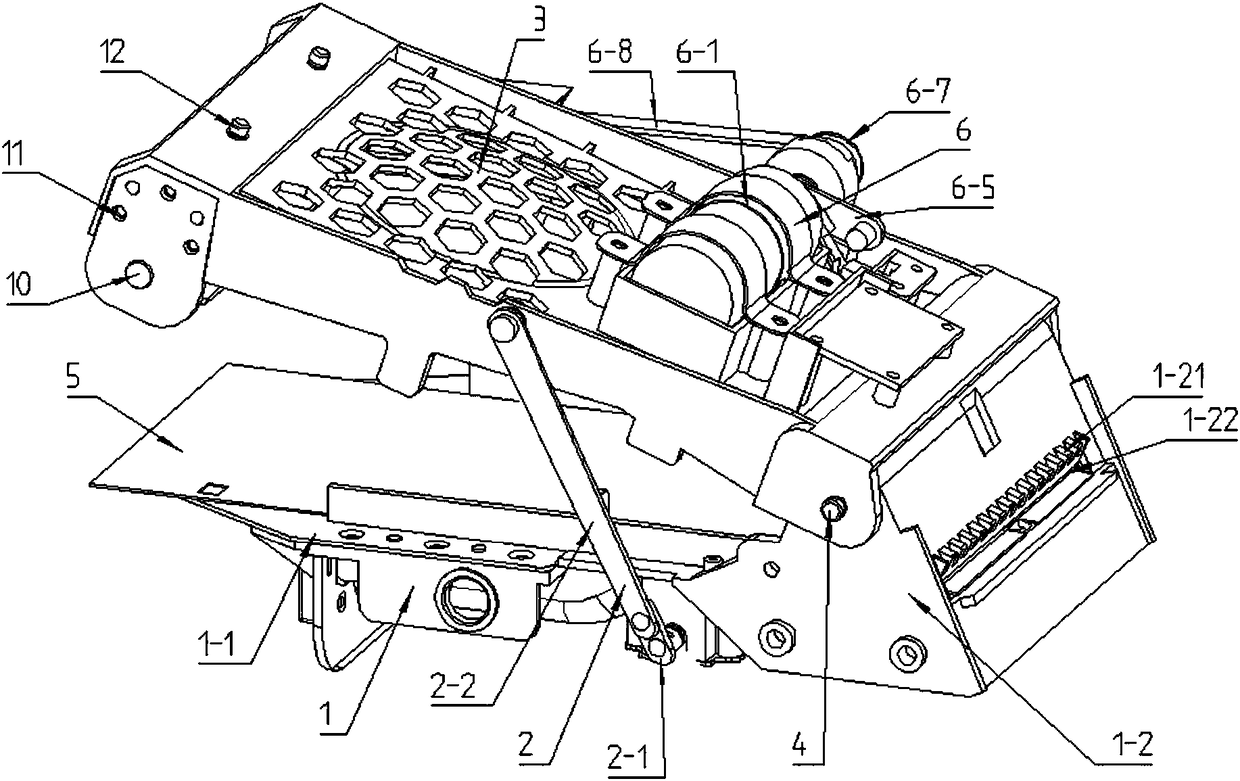

[0136] Such as Figure 1-Figure 18 and Figure 20-Figure 30 Shown, a kind of fruit bagging machine comprises machine head and fuselage, and described machine head and fuselage are connected by connector, and described fuselage comprises storage bag device 14, and described bag storage device 14 comprises storage bag box and A bag-out mechanism 14-5, the bag-out mechanism 14-5 is arranged at the bag outlet above the bag storage box, the machine head includes an upper jaw plate 3 and a lower jaw plate 1, and the upper jaw plate 3 and the lower jaw plate 1 The rear end is rotatably connected by a rotating shaft 4, and an opening and closing mechanism is provided between the upper jaw plate 3 and the lower jaw plate 1; a sealing mechanism is provided on the upper jaw plate 3, and the sealing mechanism includes a flap 10 and Turning plate driving assembly 6, the turning plate driving assembly 6 drives the turning plate 10 to rotate, and folds the opening of the fruit bag.

[0137...

Embodiment 2

[0177] Such as Figure 19 As shown, the difference from Embodiment 1 is that: the connecting component is a coupling, and the two ends of the coupling are respectively connected to the output shaft of the turning plate drive motor and the first pulley shaft.

[0178] The present invention also relates to a fruit bagging method: comprising the following steps:

[0179] Step 1. Turn on the power switch and power on the bagging machine; press the operation switch, the opening and closing motor will act, drive the opening and closing mechanism, and the upper jaw plate 3 will open;

[0180] Step 2, the bag-out motor 14-51 works, and the conveying motor 7-1 works at the same time, the bag-out mechanism 14-5 rubs the fruit bag 5 out of the storage bag box, and after the bag-out photoelectric switch detects that the fruit bag 5 is out of the bag, it is released The bag motor 14-51 stops working, and simultaneously, after the first sealing detection photoelectric switch detects that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com