Power relay plastic assembly

A power relay, plastic technology, applied in relays, electromagnetic relays, electromagnetic relay detailed information and other directions, can solve the problems of many production organization processes, short service life, complicated assembly positioning, etc., to improve creepage distance and insulation performance, improve Creepage distance and insulation, the effect of avoiding excessive pull-in voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

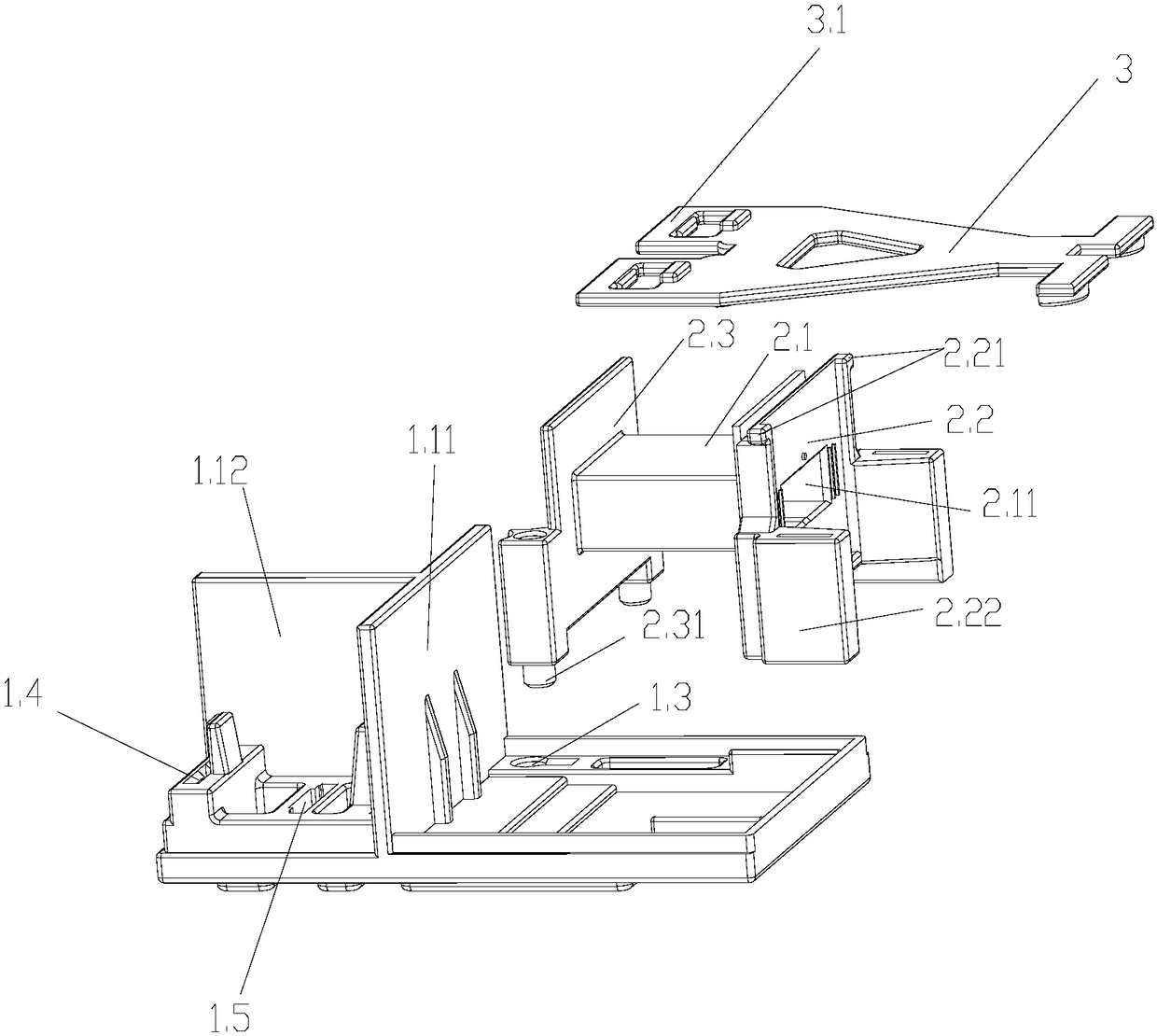

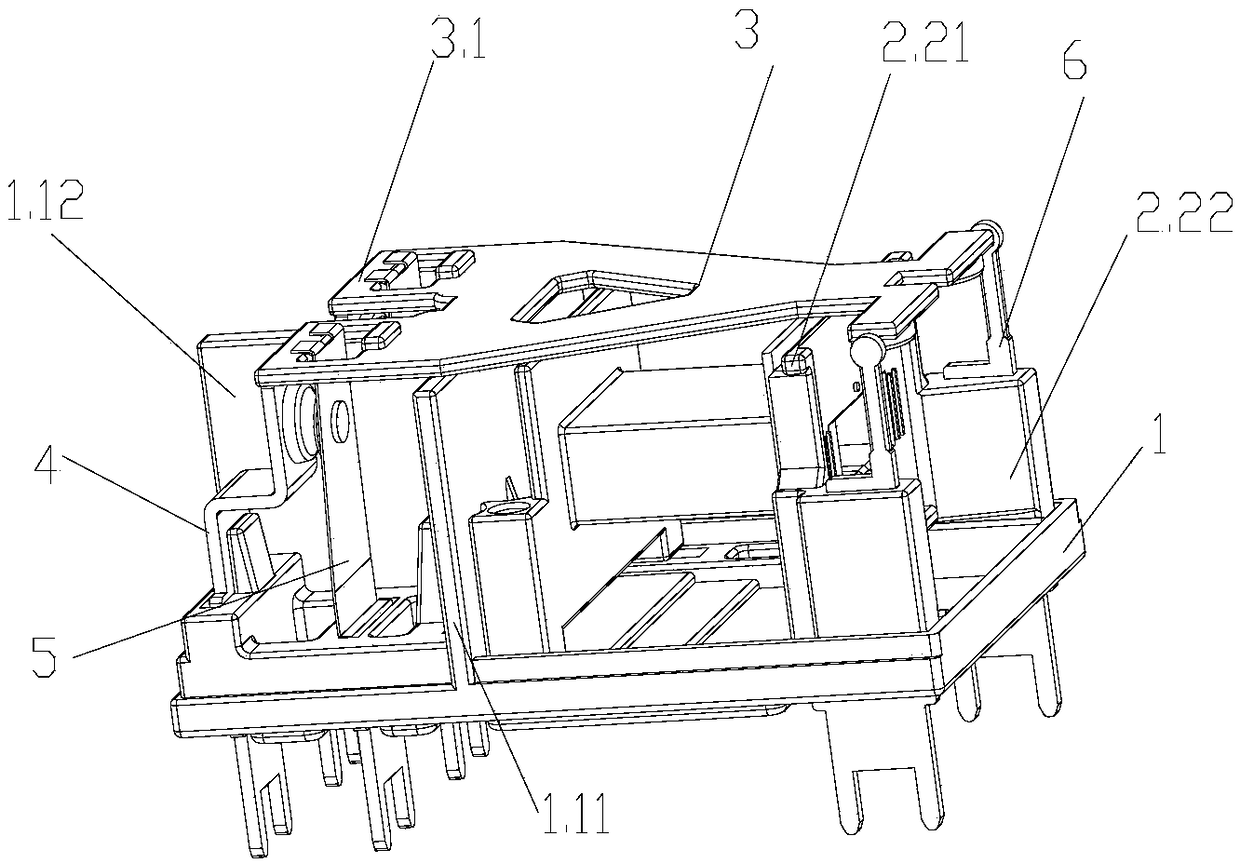

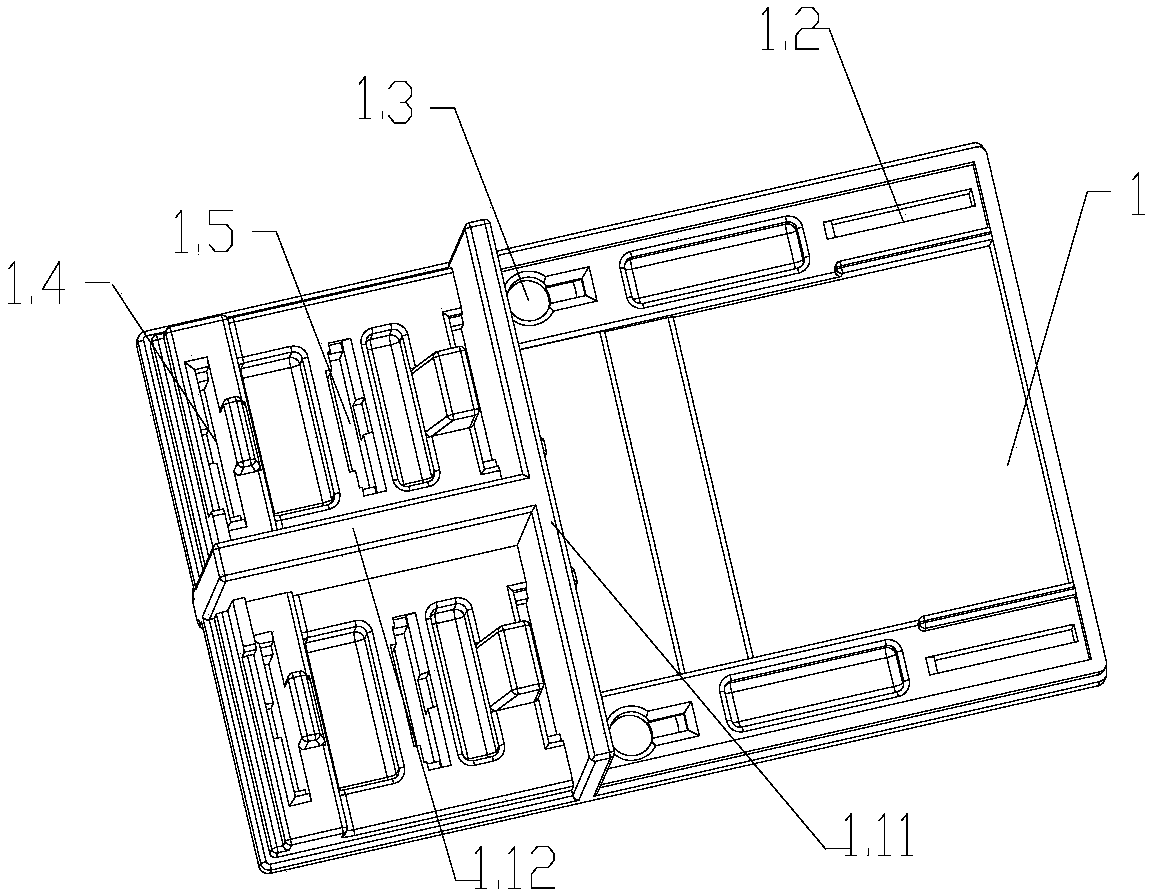

[0023] The power relay plastic assembly provided by the embodiment of the present invention has a compact structure and a small volume. Through the rational layout of the base 1, the coil frame 2 and the push rod 3, the creepage distance and insulation of the relay are improved, and the relay is effectively prevented from being caused by excessive pull-in voltage. The work is invalid, and the assembly positioning is convenient, the precision is high, and it is convenient for automatic assembly.

[0024] Such as figure 1 , figure 2 As shown, the plastic assembly of the power relay in this embodiment includes a base 1, a coil frame 2 and a push rod 3, wherein the base 1 is provided with a "T-shaped" insulating wall 1.1, which divides the base into a conductive system area and a magnetic circuit system The magnetic circuit system area is symmetrically provided with lead foot mounting holes 1.2 and positioning grooves 1.3 on the front and rear sides. The positioning shaft 2.31 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com