Multi-angle rotary arc welding equipment and automated multi-point welding workstation

A multi-angle, welding station technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high labor intensity, inability to meet high intelligence, diversification of production process, and high cost, and achieve Reduce labor intensity, ensure product quality and stability, and reduce floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

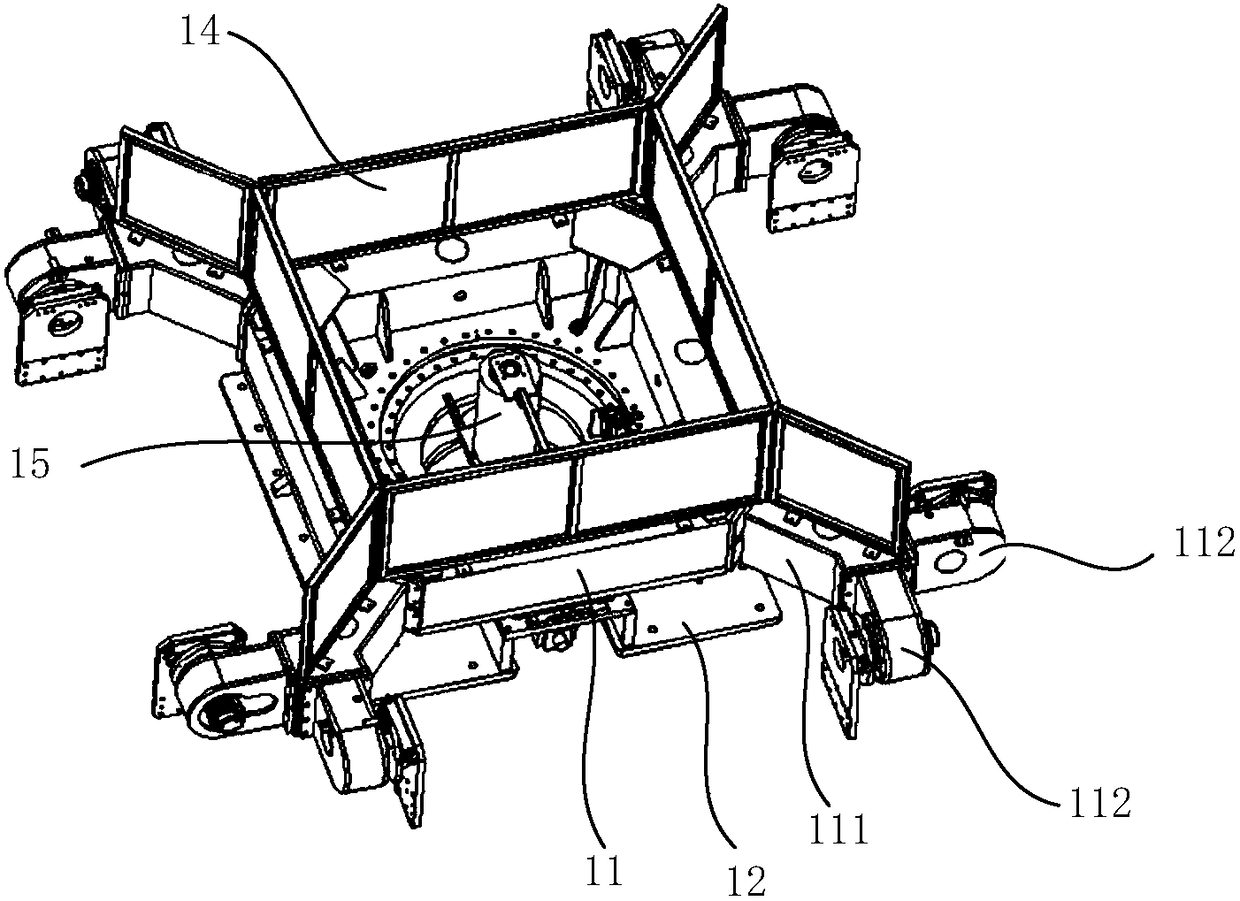

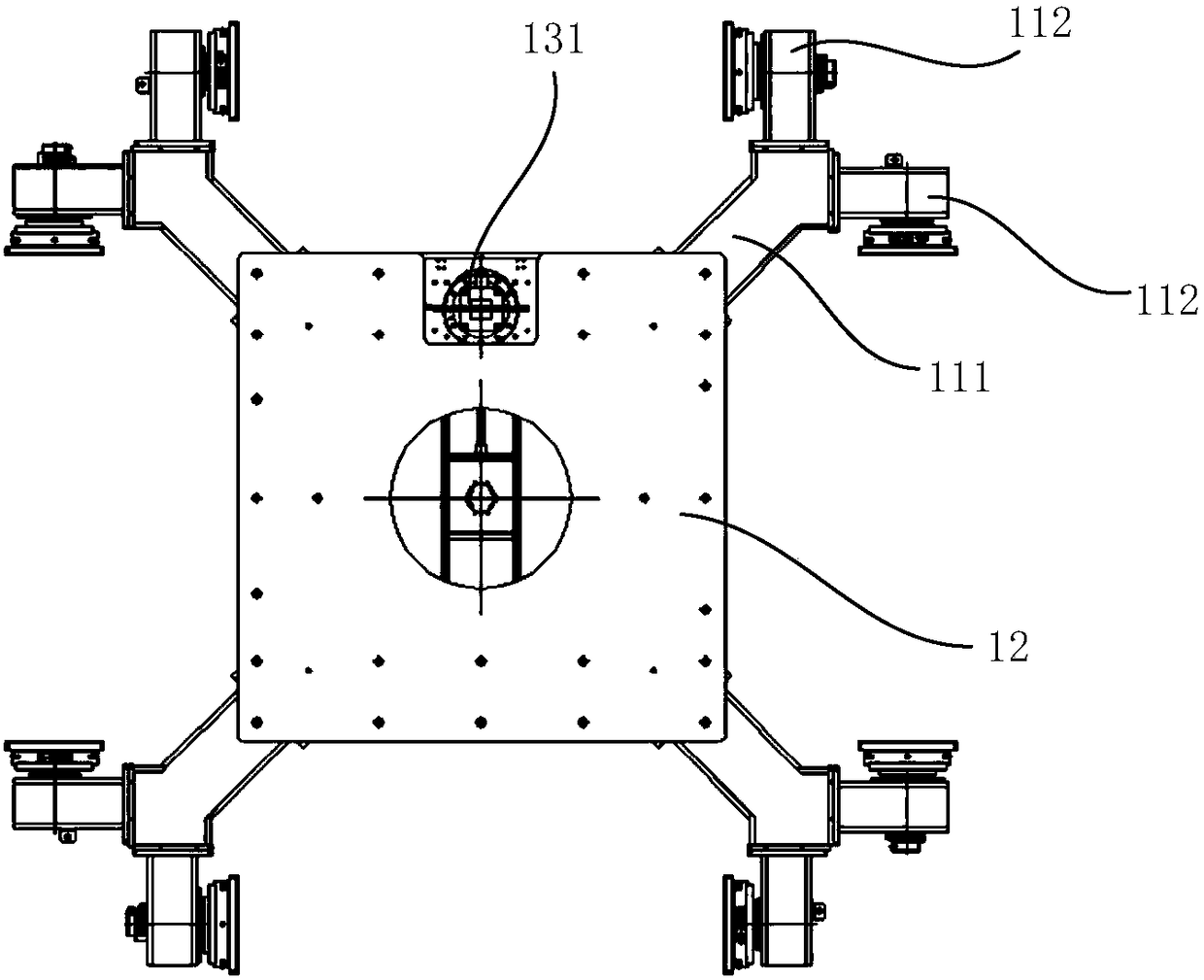

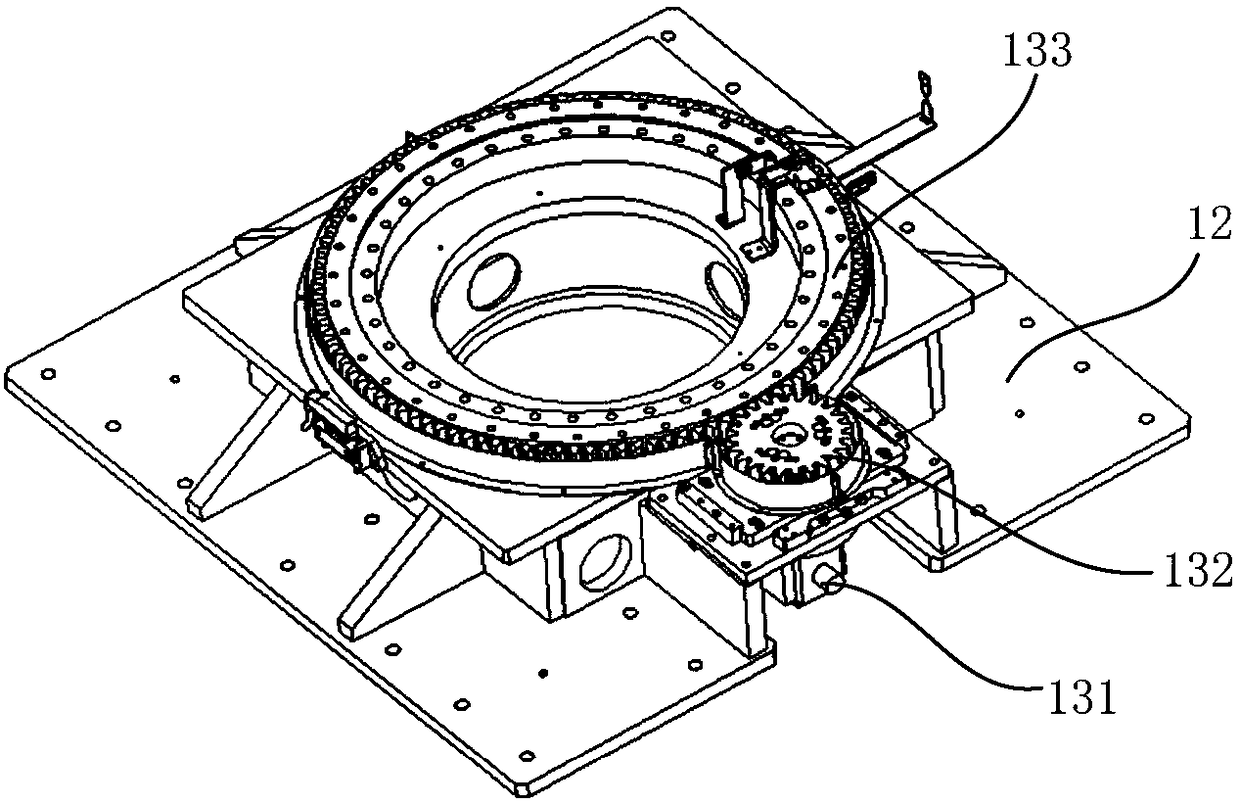

[0040] refer to figure 1 -4. The embodiment of the present invention provides a multi-angle rotary arc welding equipment, including: a control device and a large rotary device; the large rotary device includes a driving mechanism, a rotary frame 11 and a rotary fixed seat 12, and the center of the rotary frame 11 passes through the rotating shaft It is arranged on the rotary fixed seat 12 and is used to form a welding station; the driving mechanism drives and connects the rotary frame 11 to drive the rotary frame 11 to rotate around its center; the control device controls the connection to the driving mechanism.

[0041] In use, the large slewing device and the welding robot cooperate with each other to perform welding operations, wherein the large slewing device is used to form a welding station, and the welding robot performs welding operations in the welding work formed by it.

[0042] Wherein, the large slewing device includes a driving mechanism, a slewing frame 11 and a ...

Embodiment 2

[0075] refer to Figure 5 , the embodiment of the present invention provides an automatic multi-point welding workstation, including a welding robot and any kind of multi-angle rotary arc welding equipment provided in the first embodiment above; bit butt welding operation.

[0076] Among them, the specific structure of the multi-angle rotary arc welding equipment has been introduced in detail above, and will not be repeated here.

[0077] The automatic multi-point welding workstation, including the welding robot and the above-mentioned multi-angle rotary arc welding equipment, can obtain all the beneficial effects of the multi-angle rotary arc welding equipment, effectively improve the welding production efficiency, and reduce the production cost of the enterprise.

[0078] In addition, the automatic multi-point welding workstation also includes a bottom base 3, a logistics slide 31, and the like.

[0079] Specifically, the welding robot, the logistics slide 31 and the large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com