Integrated secondary vulcanization waste gas treatment device and method

A waste gas treatment device and secondary vulcanization technology, applied in the direction of gas treatment, chemical instruments and methods, combined devices, etc., can solve the problems of VOCs and deodorization effect are not obvious, can not meet the emission standard stably, and the adsorption effect of activated carbon decays quickly, etc. , to achieve the effect of good treatment effect, small footprint, compact equipment and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

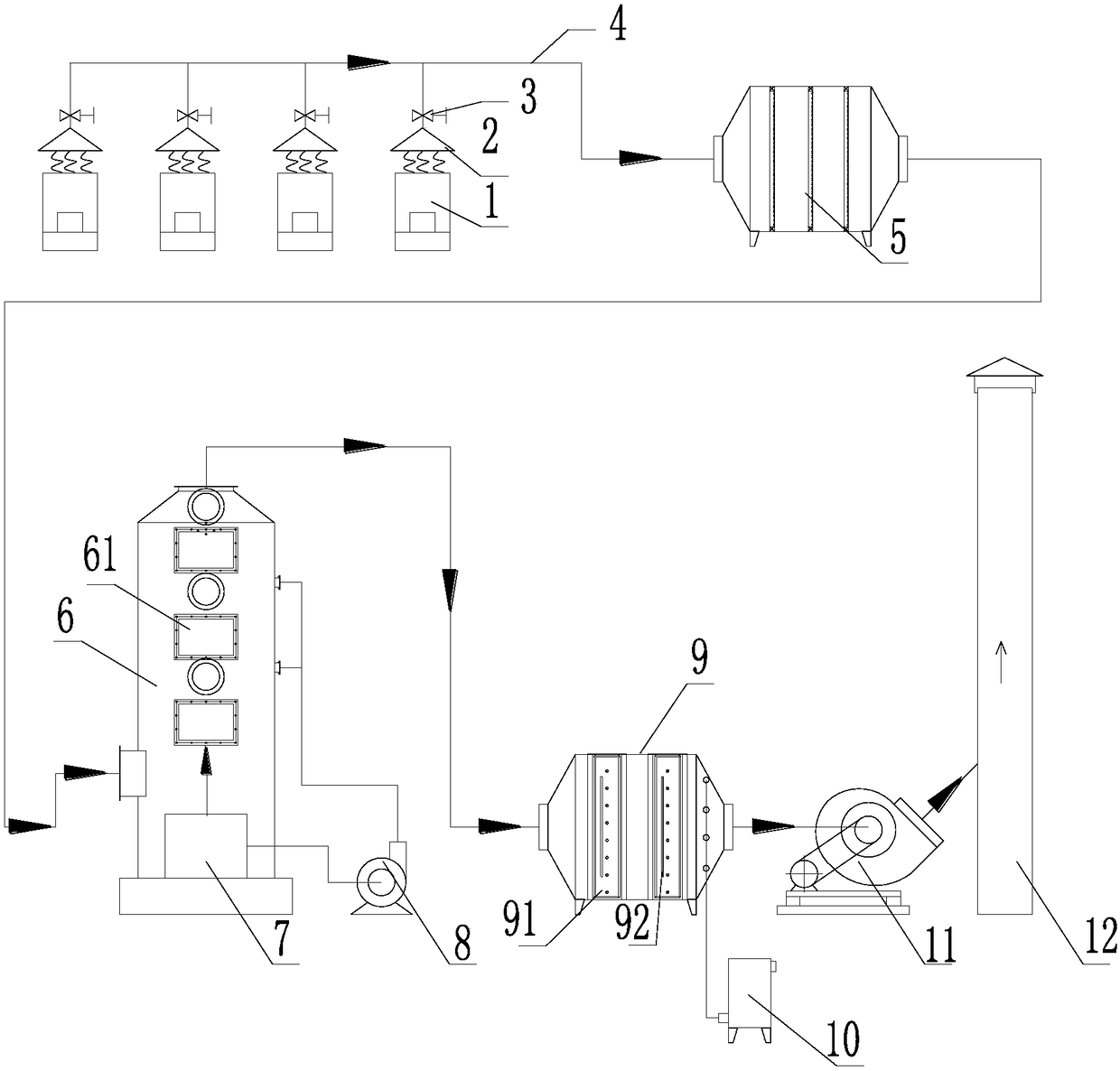

[0031] refer to figure 1 , an integrated secondary sulfidation waste gas treatment device, including a waste gas collection device, a suction filter type fume purifier 5, a spray tower 6 and an integrated purification device.

[0032] The exhaust gas collection device includes an air collecting hood 2 and an air pipe 4. The air collecting hood 2 is connected to one end of the air pipe 4, and the other end of the air pipe 4 is connected to the intake end of the suction filter oil fume purifier 5. The suction filter oil fume purifier The gas outlet of 5 is connected to the inlet of spray tower 6, the gas outlet of spray tower 6 is connected to the inlet of integrated purification equipment, and the outlet of integrated purification equipment is connected with chimney 12.

[0033] The material of the suction filter type oil fume purifier 5 is specially designed SUS304 material, and the suction filter type oil fume purifier 5 preliminarily filters the oil fume to reduce the load o...

Embodiment 2

[0055] A method for integrated secondary sulfidation waste gas treatment, comprising:

[0056] Gas collection step: each secondary vulcanizing machine is equipped with an air collecting hood 2, and the exhaust gas emitted by the secondary vulcanizing machine is absorbed by the air collecting hood 2 and then collected into the air duct 4;

[0057] Pretreatment step: the exhaust gas collected in the air duct 4 enters the suction filter type oil fume purifier 5, and the oil fume molecules in the exhaust gas are treated by the suction filter type oil fume purifier 5, and the oil fume is preliminarily filtered to obtain the primary treatment gas;

[0058] Primary treatment step: the primary treatment gas is transported to the spray tower 6, the spray water in the spray tower 6 is sprayed in the form of mist, and the sprayed primary treatment gas is dewatered to obtain the secondary treatment gas;

[0059] Secondary treatment step: the secondary treatment gas is transported to the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com