Double-diaphragm air compression damper

An air compression and shock absorber technology, applied in gas shock absorbers, shock absorbers, shock absorbers, etc., can solve problems such as waste of energy and environmental pollution, achieve high air compression efficiency, low manufacturing and maintenance costs, Simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

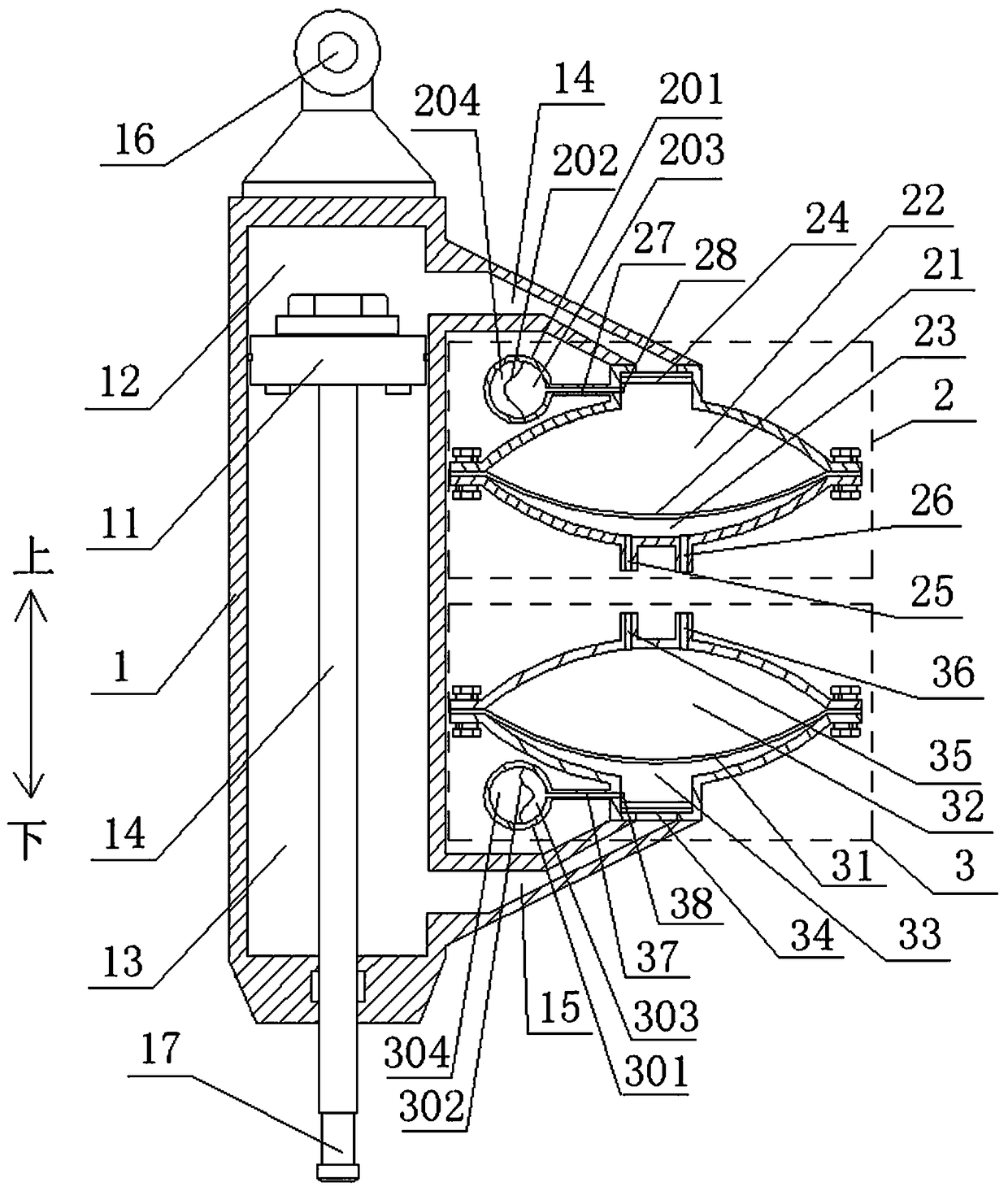

[0026] Such as figure 1 As shown, taking the direction shown by the arrow in the figure as the up and down direction, the double-diaphragm air compression shock absorber of the present invention includes a sleeve 1 , an upper diaphragm compressor 2 and a lower diaphragm compressor 3 .

[0027] The sleeve 1 is provided with a sealing piston 11, the sealing piston 11 divides the sleeve into a first upper oil chamber 12 and a first lower oil chamber 13 which are not connected to each other, the sealing piston 11 is fixedly connected with a piston rod 14, the piston The rod 14 runs through the first lower oil chamber 13 and extends downwards to the outside of the sleeve 1. A gasket is provided between the part of the pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com