T beam prefabricated plant

A technology of prefabrication field and pedestal, which is applied in manufacturing tools, industrial buildings, ceramic molding machines, etc., can solve the problems of large volume of T beams, difficult adjustment, low production transfer efficiency, etc., and achieves convenient material acquisition, easy installation and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

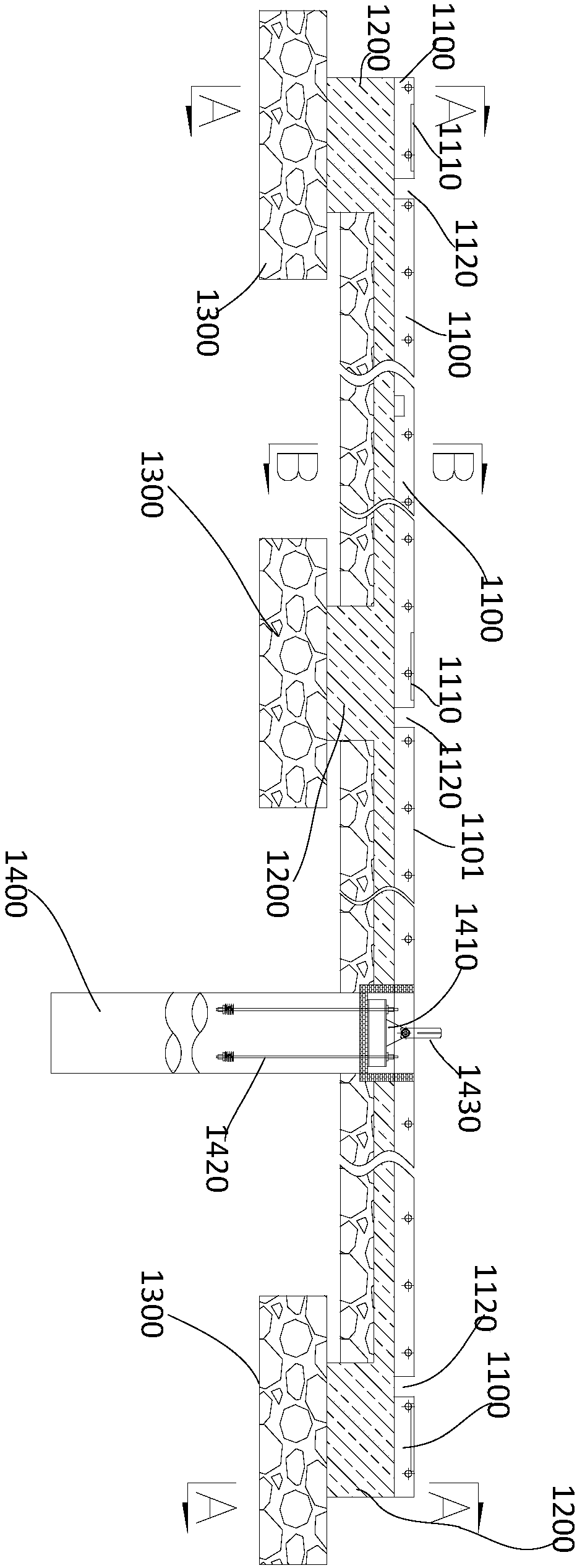

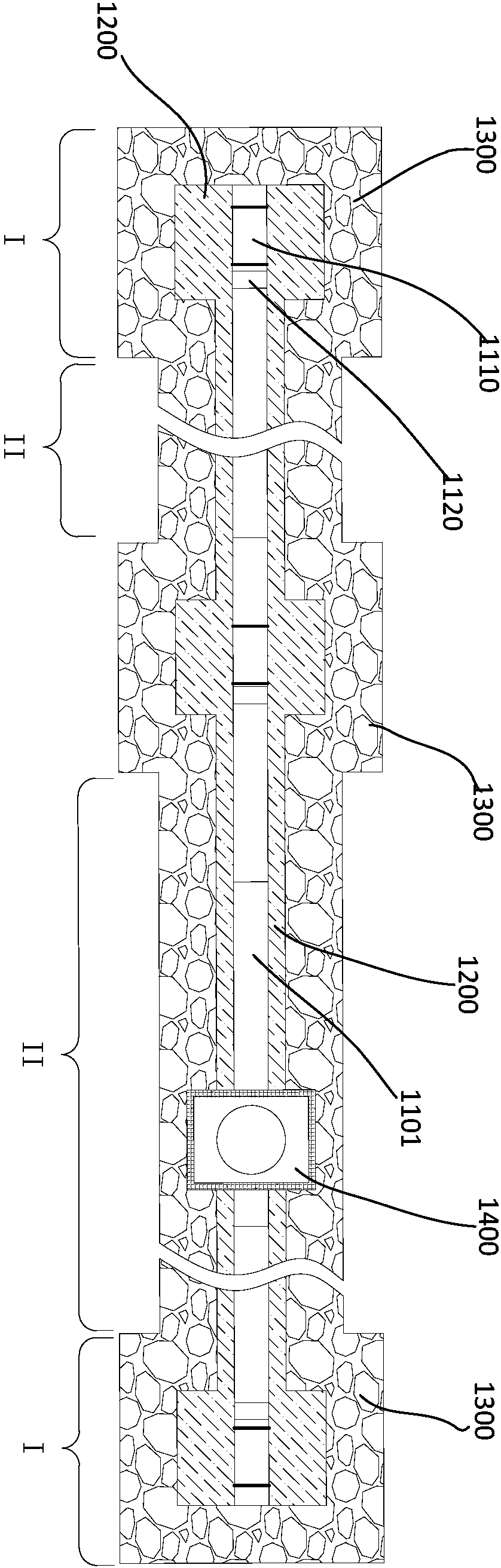

[0030] The present invention will be further described below with reference to the accompanying drawings and exemplary embodiments, wherein the same reference numerals in the drawings all refer to the same components. Also, detailed descriptions of known arts will be omitted if they are unnecessary to illustrate the features of the present invention.

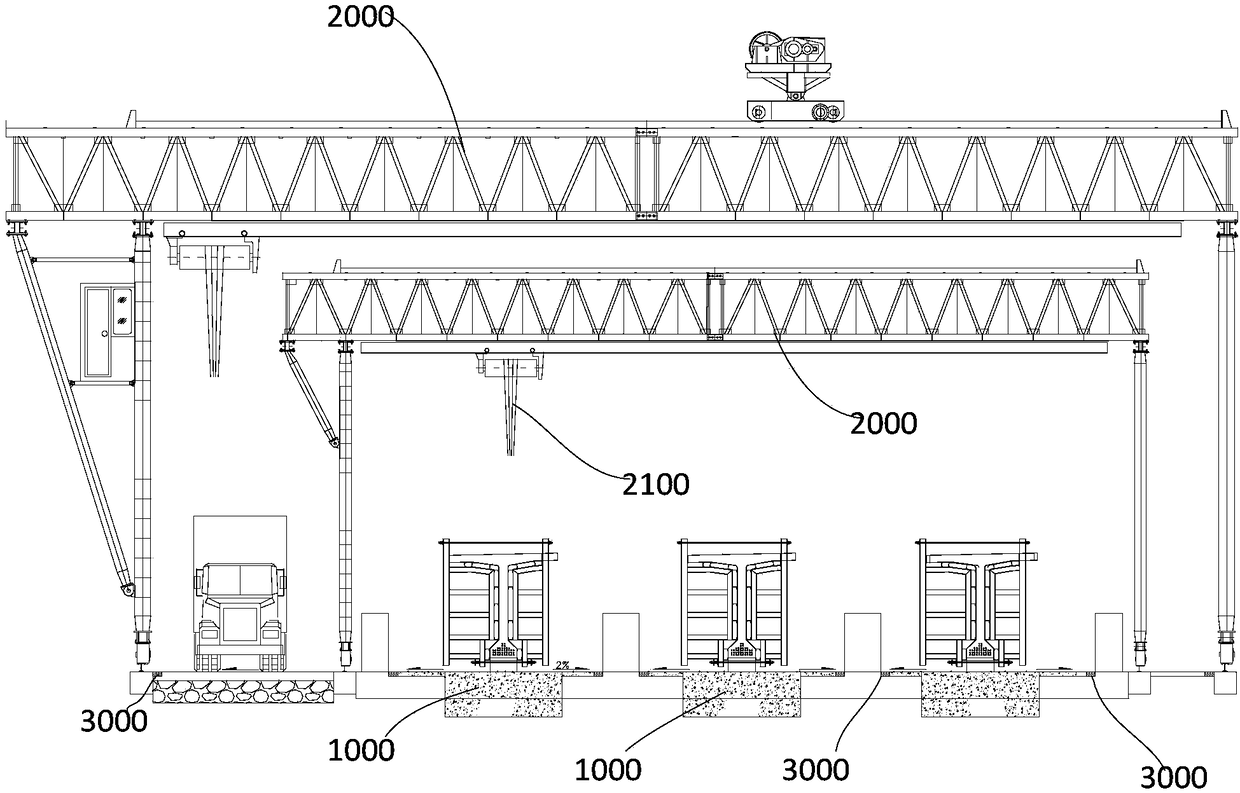

[0031] Such as figure 1 As shown, the T-beam prefabrication field provided in an embodiment of the present invention includes a lifting system 2000, a drainage system 3000 and several pedestal structures 1000, wherein the lifting system 2000 adopts a gantry crane, and the gantry crane is provided with an electric hoist 2100 with a certain load specification. The drainage system 3000 is mainly formed by setting a drainage ditch on the site, and a drainage ditch is arranged near each pedestal structure 1000 , and the drainage ditch is parallel to the longitudinal direction of the pedestal structure 1000 . For example, the T-beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com