Perpendicular paving device for flexible coiled materials

A technology of laying devices and coiled materials, which is applied in the direction of protection devices, buildings, and infrastructure engineering, etc. It can solve the problems of inability to guarantee the quality of product laying, difficulty in construction schemes, and high construction requirements, so as to improve the flatness of the tank wall and protect against Effects of damage and simplification of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

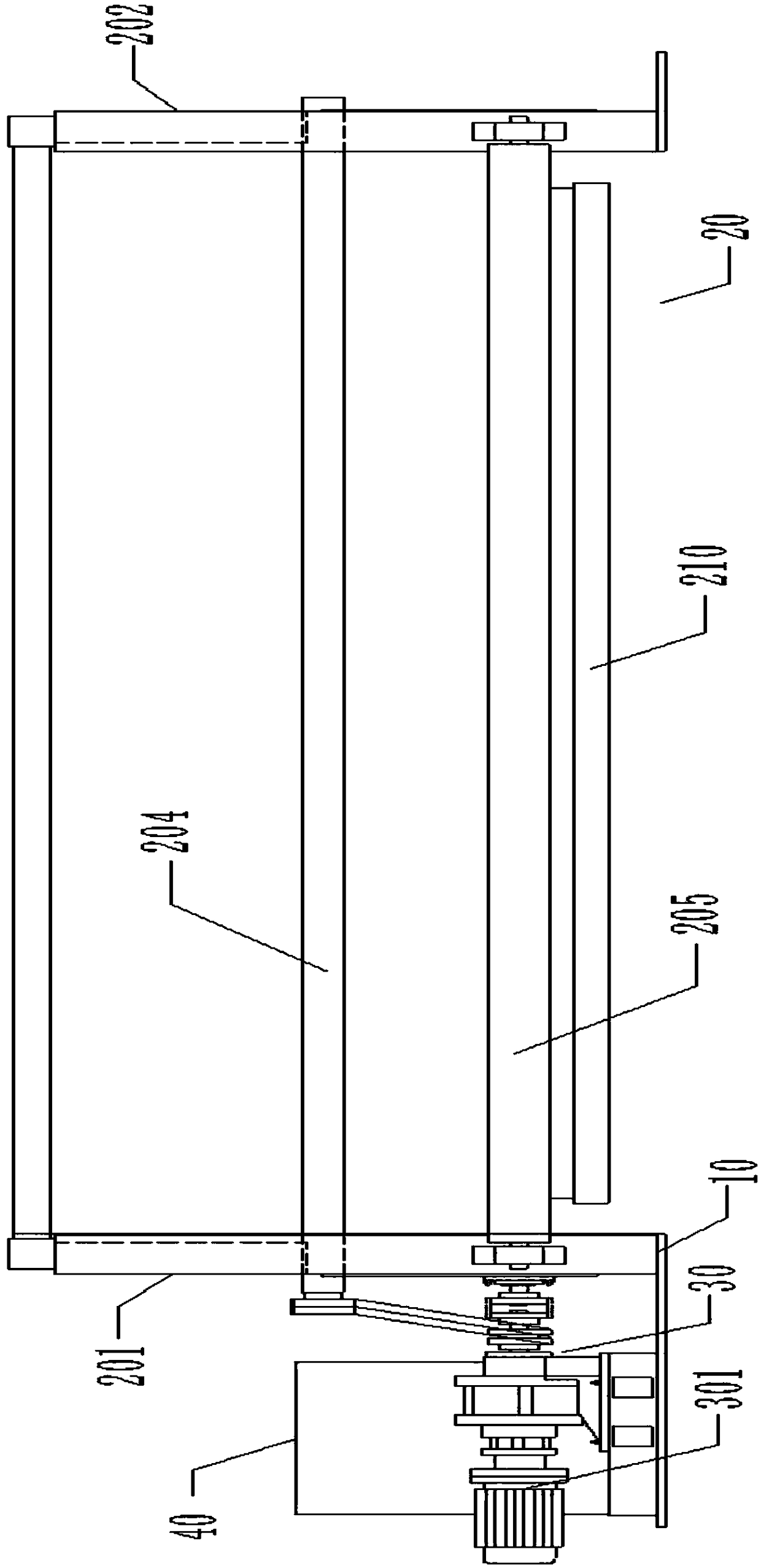

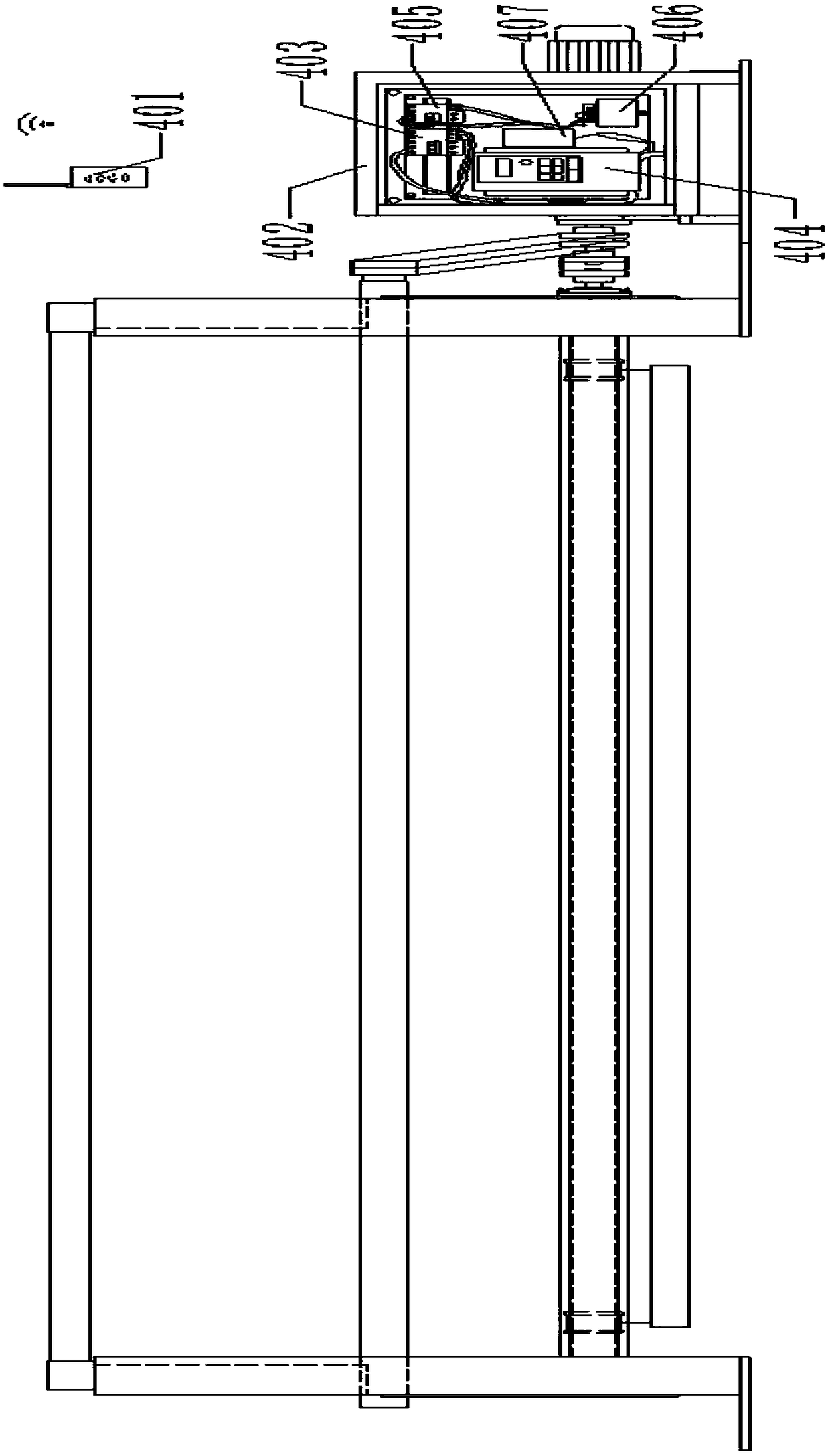

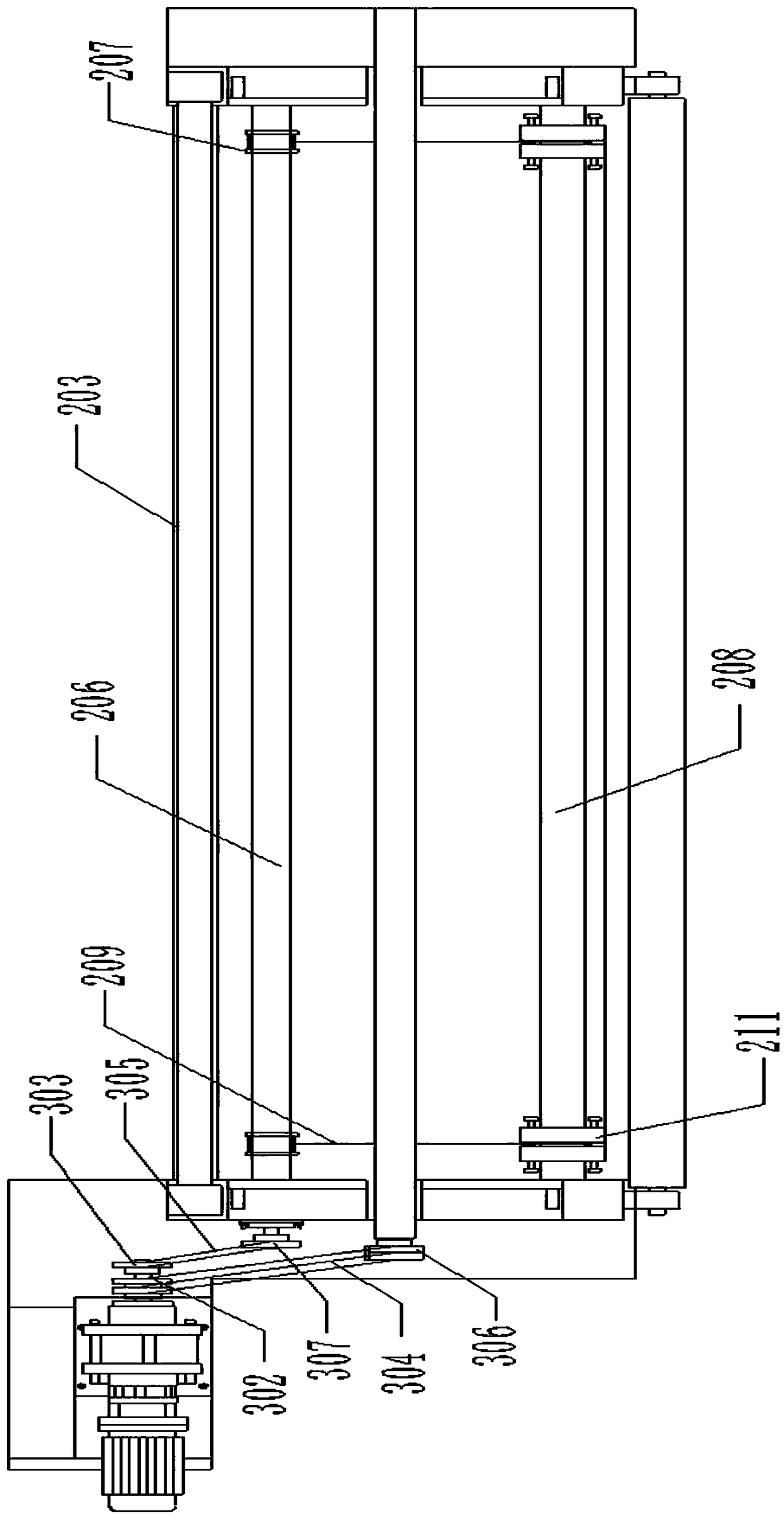

[0035] like Figure 1-Figure 7 As shown, a flexible coil vertical laying device includes a base 10, a coil auxiliary laying part 20, a power part 30 and a control part 40, and the coil auxiliary laying part 20, the power part 30 and the control part 40 are set on the base 10, The input end of the coil auxiliary laying part 20 is connected to the output end of the power part 30, and the power part 30 is set to be electrically connected to the control part 40, and the start and stop of the power part 30 is controlled by the control part 40, so that the power part 30 drives the coil auxiliary part. The laying part 20 is working, so as to complete the laying of flexible coils such as GCL, PE film and composite geomembrane along the vertical direction of the groove to be laid, and the operation is simpl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com