Dual-sealing mechanism for tank cover of aluminum melt degasification tank

A technology of aluminum melt and double sealing, which is applied in the direction of furnace, charge composition/state, furnace charge, etc., can solve problems affecting the normal operation of equipment, and achieve the effect of improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

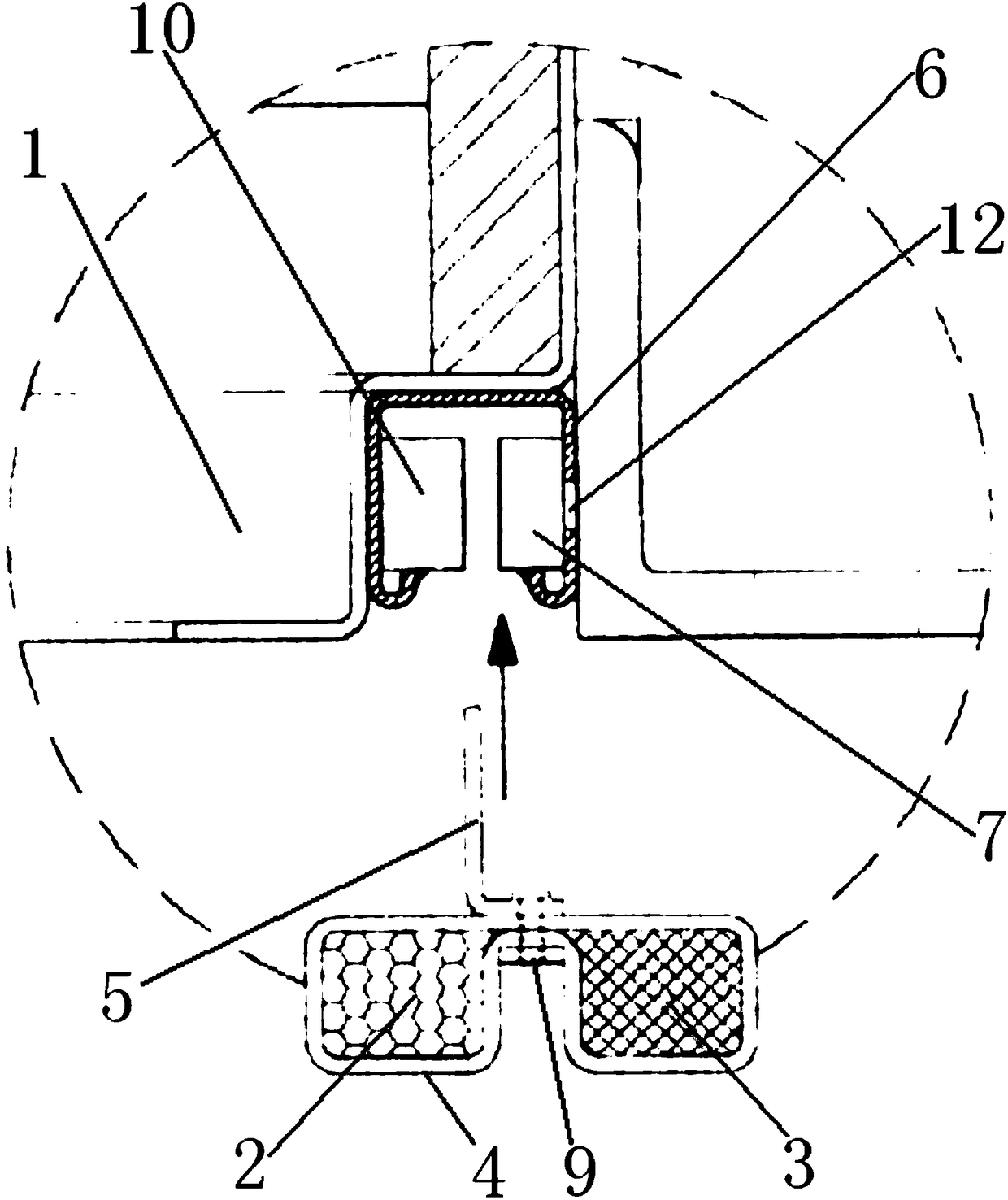

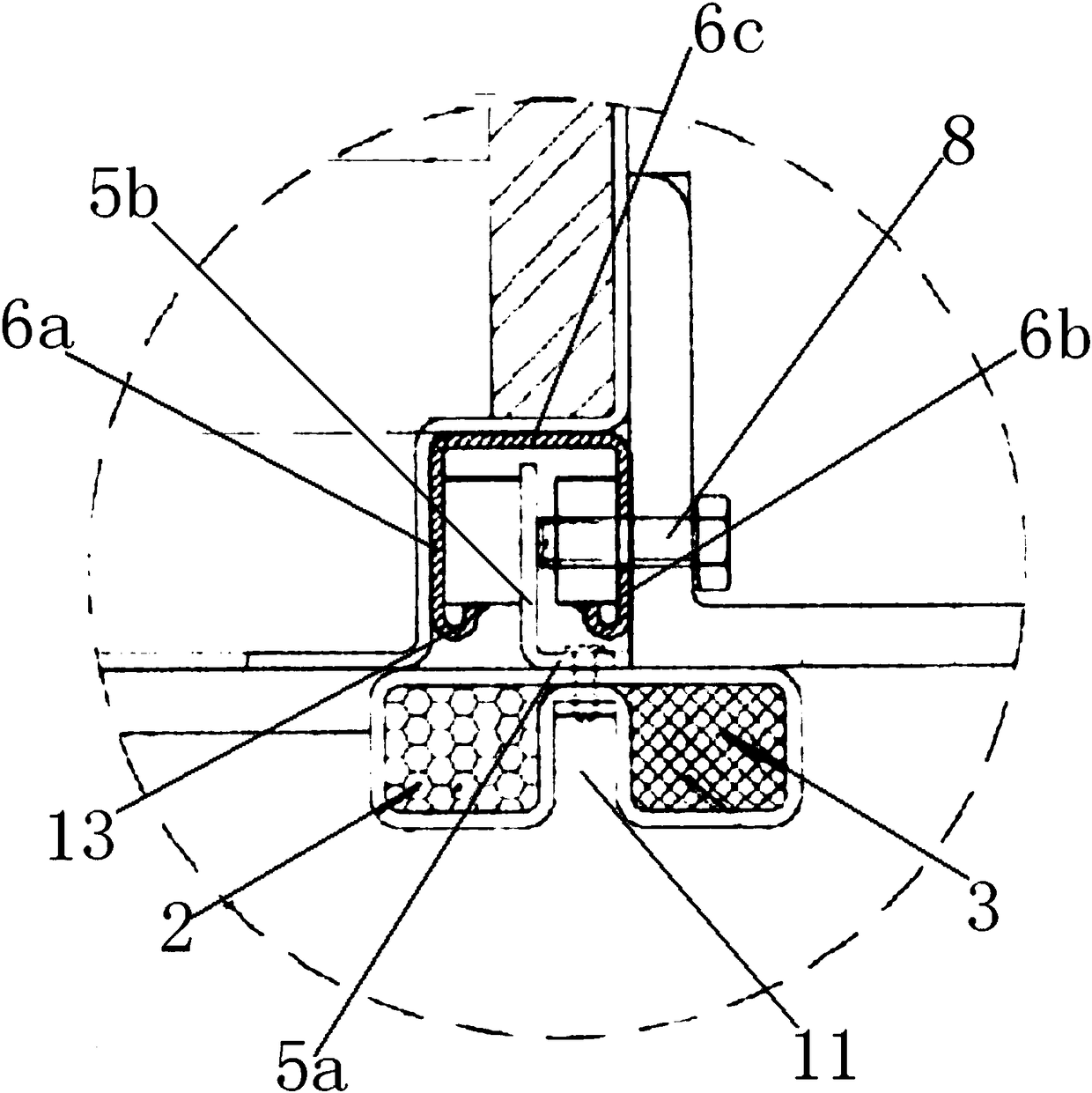

[0030] In order to achieve the purpose of the present invention, a kind of double-sealing mechanism of aluminum melt degassing box cover comprises: inner sealing strip 2; Outer sealing strip 3, with respect to inner sealing strip 2, outer sealing strip 3 is away from the side of degassing box Furnace cavity; the wrapping cloth 4 wraps the inner sealing strip 2 and the outer sealing strip 3; the L-shaped piece 5 is composed of two first flat plates 5a and second flat plates 5b which are vertically connected to each other, and the first flat plate 5a is connected and fixed to the bead 9, The inner side of the wrapping cloth 4 is attached, and the inner sealing strip 2 and the outer sealing strip 3 are separated to form a gap groove 11. The bead 9 is located at the bottom of the gap groove 11, and the second flat plate 5b is connected and fixed with the box cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com