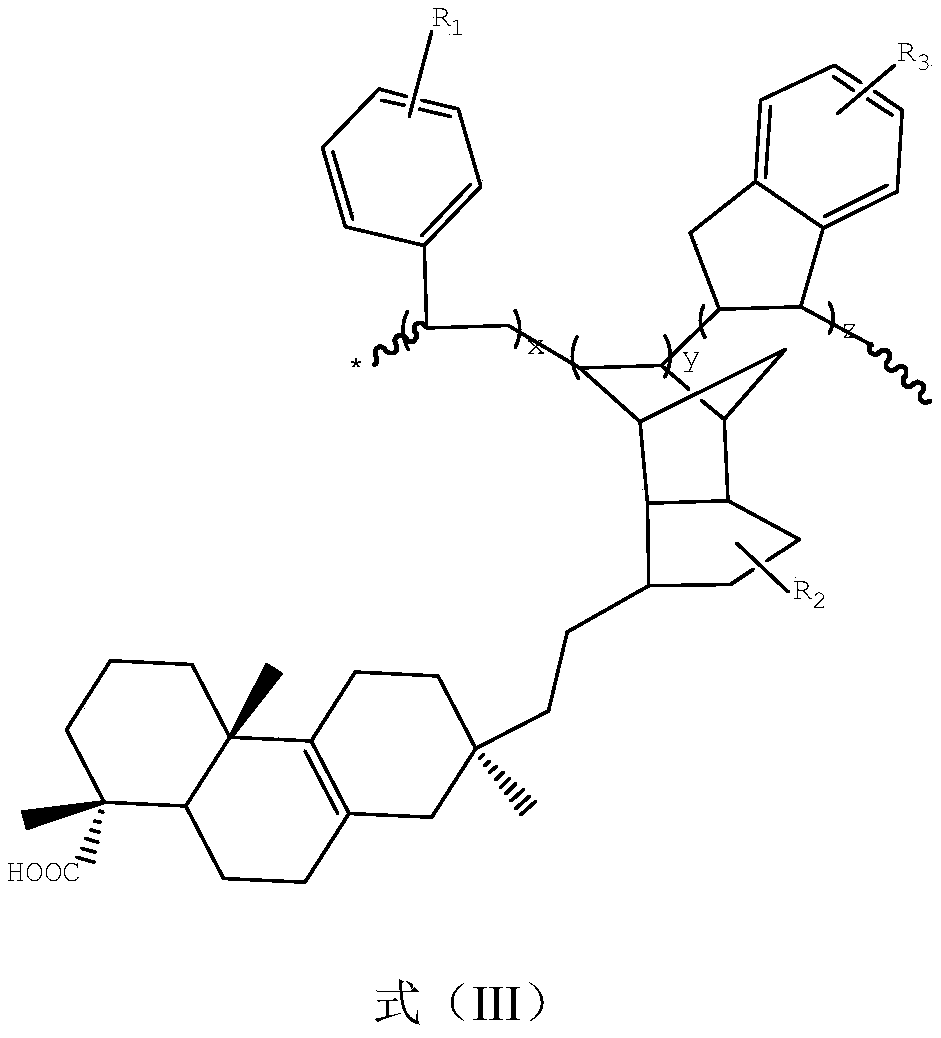

C9 petroleum resin modified by rosin and its preparation method and application

A technology of rosin modification and petroleum resin, applied in the field of chemistry, can solve problems such as performance index decline, and achieve the effects of improving wet grip, increasing glass transition temperature, and increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Put 30 parts of toluene and 2 parts of aluminum trichloride catalyst into the reactor, vent the water out of the system with nitrogen, and add dropwise a mixture of 10 parts of toluene, 60 parts of styrene and 30 parts of rosin. The time of dripping is 1h. After the addition was completed, the temperature of the reaction was maintained at 40°C, and 20 parts of 10% sodium hydroxide solution was added dropwise after the reaction for 2 hours. Stop stirring, remove the upper layer of liquid and wash with water after layering, until the pH of the lower layer of Qingye is between 6-8, distill the upper layer of liquid and vacuum distillation to remove excess solvent, and finally get 70 parts of yellow resin, the softening point of the resin is at 91°C. The rosin has an iodine value of 180.

Embodiment 2-9

[0043] Table-1 shows the raw material ratio of the rosin-modified C9 petroleum resin prepared in Preparation Example 2-9 and the softening point of the prepared resin. The operation steps are the same as in Example 1.

[0044] Table 1

[0045]

Embodiment 10

[0047] The solvent in Example 1 was replaced with 60 parts, and the rest remained unchanged. Finally, 65 parts of resin was obtained with a softening point of 91°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com