Coal mill gearwheel oil injection device and control method thereof

A technology of fuel injection device and control method, which is applied in the direction of grain processing, etc., which can solve the problems of poor man-machine communication of secondary meters and inability to display in Chinese, and achieve the effects of eliminating hidden dangers, facilitating equipment maintenance, and eliminating system abnormalities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

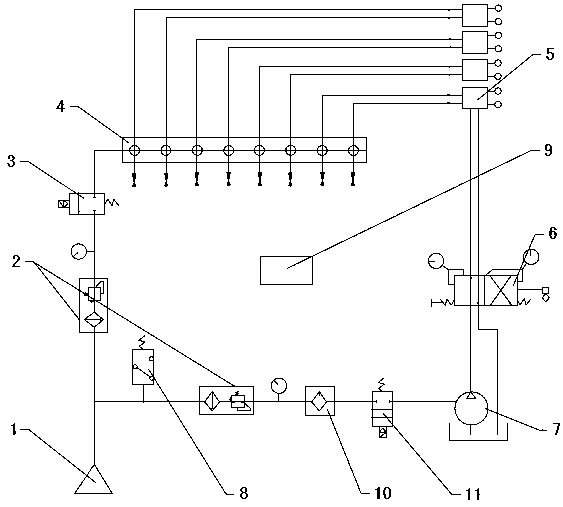

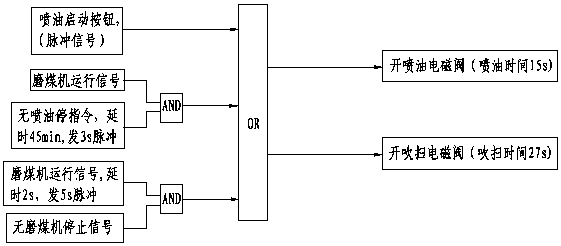

[0032] Figure 1~4 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~4 The present invention will be further described.

[0033] like figure 1 As shown, this embodiment includes a purge circuit, an oil injection circuit, an oil injection output mechanism, an air compression mechanism and a control module, and also includes a display screen. The output mechanism is connected, the input ends of the fuel injection circuit and the purge circuit are respectively connected with the air compression mechanism, and a fault monitoring mechanism is set on the fuel injection circuit; the fuel injection mechanism in the fuel injection circuit and the purge mechanism in the purge circuit are respectively connected to control module, the output end of the fault monitoring mechanism is connected to the input end of the control module, and the input end of the display screen is connected to the control module. The control module in this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com