Preparation method and application of a composite modified straw activated granular carbon adsorption material

一种复合改性、活性颗粒的技术,应用在农林业废弃物资源化和水处理领域,能够解决吸附效果不佳、易掉渣、改性秸秆生物炭难以挥手等问题,达到降低富营养化现象、提高吸附能力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

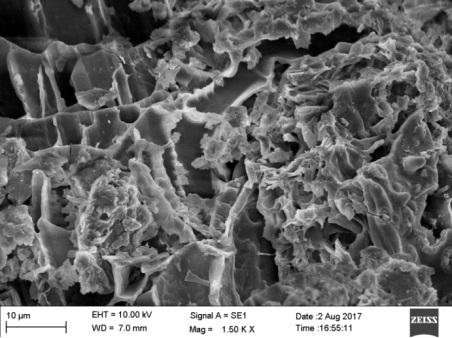

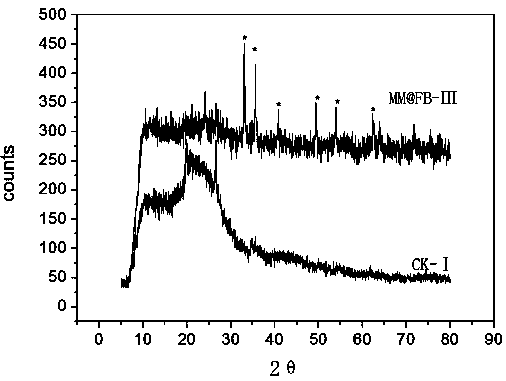

[0036] Example 1 Preparation of composite modified straw activated granular carbon adsorption material

[0037] A) Preparation of straw granular carbon

[0038] 1) Straw composite particles: Premix 1000g rice straw powder with a particle size of 40~60 mesh, 1500g distilled water, 100g methylcellulose, 125g nano-montmorillonite and 125g negative ion powder in a high-speed mixer for 30 minutes, and then transfer the materials To the turntable granulator, the inclination angle of the turntable is set to 30°, and the rotation speed is 20rpm for granulation to obtain straw composite granules with a particle size range of 0.5-6mm.

[0039] 2) Preparation of straw granular carbon: put the straw granular carbon in a tube furnace for pyrolysis at a heating rate of 5°C / min, and pyrolyze at 350°C for 6h;

[0040] B) Preparation of composite modified straw activated granular carbon

[0041] 1) Put 200mL magnesium chloride solution with a molar concentration of 0.85mol / L and 100mL ferric...

Embodiment 2

[0046] A) Preparation of straw granular carbon

[0047] 1) Straw composite granules: Premix 1000g coconut shell powder, 500g distilled water, 800g methyl cellulose and 200g methyl hydroxyethyl cellulose with a particle size of 40~60 mesh in a high-speed mixer for 5 minutes, and then transfer the materials to Turntable granulator, the inclination angle of the turntable is set to 60°, and the rotating speed is 60rpm for granulation to obtain straw composite granules with a particle size range of 0.5-6mm.

[0048] 2) Preparation of straw granular carbon: put the straw granular carbon in a tube furnace for pyrolysis at a heating rate of 10°C / min, and pyrolyze at 750°C for 1 hour;

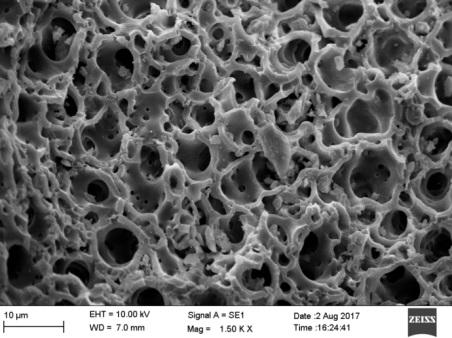

[0049] B) Preparation of composite modified straw activated granular carbon

[0050] 1) Put 200mL magnesium chloride solution with a molar concentration of 0.55mol / L, 50mL ferric chloride solution with a molar concentration of 0.45mol / L, and 50mL aluminum chloride solution with a molar concentration of...

Embodiment 3

[0053] A) Preparation of straw granular carbon

[0054] 1) Straw composite particles: 1000g wheat straw powder with a particle size of 40~60 mesh, 800g distilled water, 400g methyl cellulose and 600g methyl hydroxyethyl cellulose, 150g nano-montmorillonite and 100g negative ion powder in a high-speed mixer The mixture was premixed for 15 minutes, and then the material was transferred to a turntable granulator. The inclination angle of the turntable was set at 45°, and the rotation speed was 40rpm for granulation to obtain straw composite granules with a particle size range of 0.5-6mm.

[0055] 2) Preparation of straw granular carbon: put the straw granular carbon in a tube furnace for pyrolysis at a heating rate of 8°C / min, and pyrolyze at 450°C for 4h;

[0056] B) Preparation of composite modified straw activated granular carbon

[0057] 1) Put 200mL magnesium chloride solution with a molar concentration of 0.55mol / L, 50mL ferric chloride solution with a molar concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com