Novel tobacco preparation device

A technology for preparing a device and tobacco, applied in the directions of tobacco, tobacco processing, application, etc., can solve the problems of a single crushing operation, uneven size of tobacco leaves, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

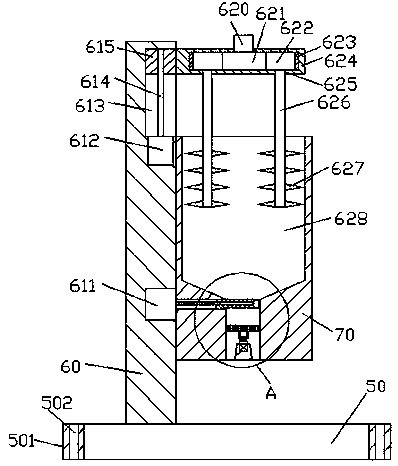

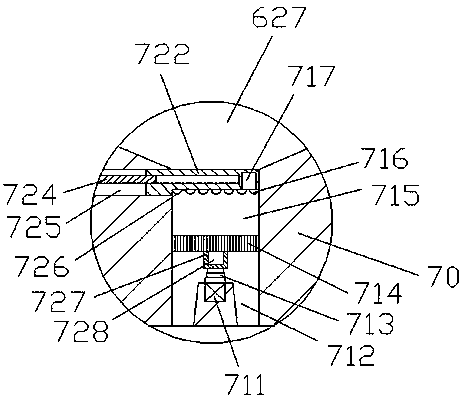

[0015] Combine below Figure 1-4 The present invention will be described in detail.

[0016] refer to Figure 1-4 , a new type of tobacco preparation device according to an embodiment of the present invention, comprising a stand 50 fixedly installed on the bottom end surface of the column 60 and a housing box 70 fixedly installed on the right end surface of the column 60, the four stands 50 Fixed blocks 501 are provided on the corners and each fixed block 501 is provided with a fixed hole 502, and the fixed holes 502 are used to cooperate with fastening bolts to fix the stand 50 on the ground, so that The stability during fixing can be increased. A telescopic device is arranged on the right side end surface of the column 60 on the upper side of the accommodation box 70. An accommodation chamber 628 is arranged on the top end surface of the accommodation box 70. The inner bottom of the accommodation chamber 628 The wall communicates with a pushing cavity 715, and a first slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com