Under-film PVC piping manifold structure used for circulating fumigation

A pipeline network and pipeline technology, applied in the application, capture or killing device of insects, animal husbandry and other directions, can solve the problem of large amount of medicine consumption and workload, and achieve the effect of improving efficiency, improving fumigation efficiency and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

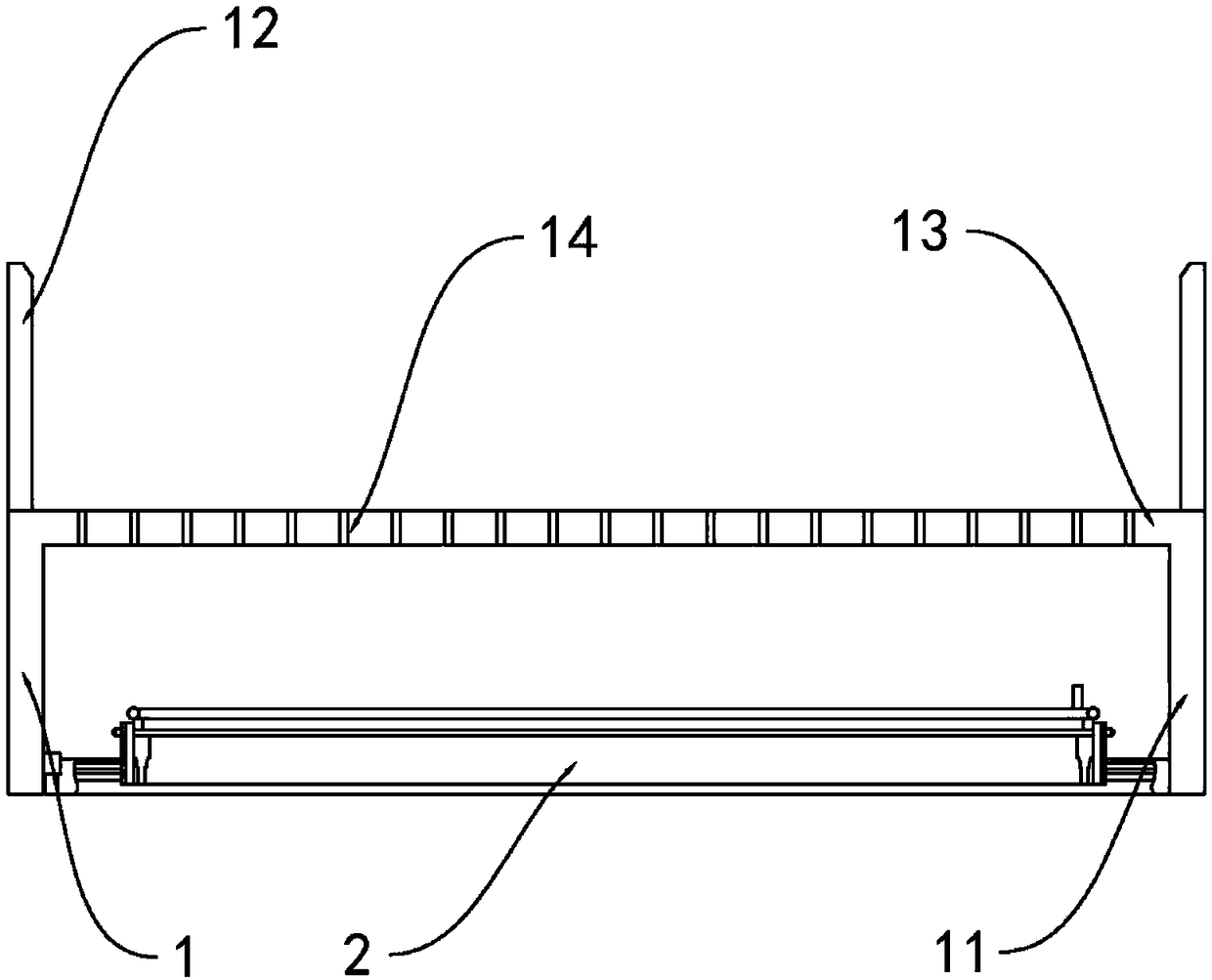

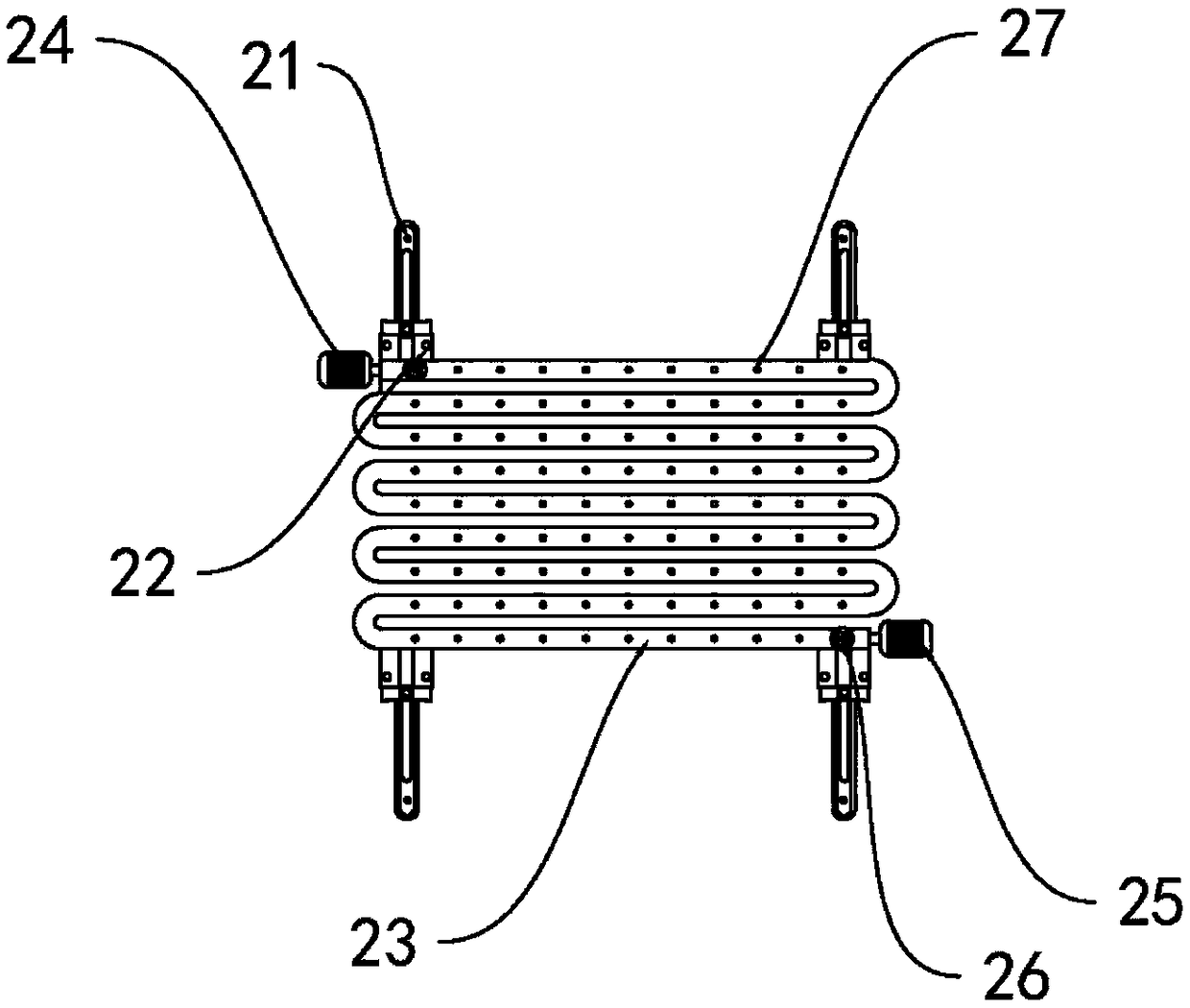

[0021] As shown in the figure, this embodiment provides a PVC pipe network structure under the membrane for circulation fumigation, including a support platform 1 for holding grains, and a fumigation mechanism 2 for drug fumigation, and the fumigation mechanism 2 is arranged on Below the support platform 1, the fumigation mechanism 2 includes a fixed track 21, a sliding block 22, a PVC pipe 23 under the S-shaped film, a first blower 24, a second blower 25, a filling port 26, and a fumigation hole 27. The fixed track 21 is arranged directly below the support platform 1, and the PVC pipe 23 under the S-shaped film is installed on the fixed track 21 through the sliding block 22, and the first blower 24 and the second blower 25 are respectively connected with the PVC pipe 23 under the S-shaped film. The connecting section is connected, the filling port 26 is opened at the end of the PVC pipe 23 under the S-shaped membrane, and the fumigation holes 27 are evenly distributed on the u...

Embodiment 2

[0024] This embodiment has made the following optimizations on the basis of Embodiment 1: As shown in the figure, this embodiment provides a PVC pipe network structure under the film for circulation fumigation, including a support platform 1 for holding grain, For the fumigation mechanism 2 for drug fumigation, the fumigation mechanism 2 is arranged under the support platform 1, and the fumigation mechanism 2 includes a fixed rail 21, a sliding block 22, a PVC pipe 23 under the S-shaped film, a first blower 24, a second Blower 25, filling port 26, fumigation hole 27, described fixed rail 21 is arranged on the right below of support platform 1, and the PVC pipe 23 under the described S-type membrane is installed on the fixed rail 21 by slide block 22, and described first blower 24 and the second blower 25 communicate with the segment of the PVC pipeline 23 under the S-shaped membrane respectively, the filling port 26 is set at the end of the PVC pipeline 23 under the S-shaped me...

Embodiment 3

[0028] This embodiment has made the following optimizations on the basis of Embodiment 1: As shown in the figure, this embodiment provides a PVC pipe network structure under the film for circulation fumigation, including a support platform 1 for holding grain, For the fumigation mechanism 2 for drug fumigation, the fumigation mechanism 2 is arranged under the support platform 1, and the fumigation mechanism 2 includes a fixed rail 21, a sliding block 22, a PVC pipe 23 under the S-shaped film, a first blower 24, a second Blower 25, filling port 26, fumigation hole 27, described fixed track 21 is arranged on the just below of support platform 1, and the PVC pipe 23 under the described S-shaped membrane is installed on the fixed track 21 by sliding block 22, and described first blower 24 and the second blower 25 communicate with the segment of the PVC pipeline 23 under the S-shaped membrane respectively, the filling port 26 is set at the end of the PVC pipeline 23 under the S-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com