Pressure-adjusting structure for double-force-type vice

A technology of double-force vise, which is applied in the field of pressure-regulating structure of double-force vise, can solve the problems of not having double-power booster clamping effect, laborious operation process, difficult operation, etc., and achieves fewer components, Smooth and firm clamping, easy to assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

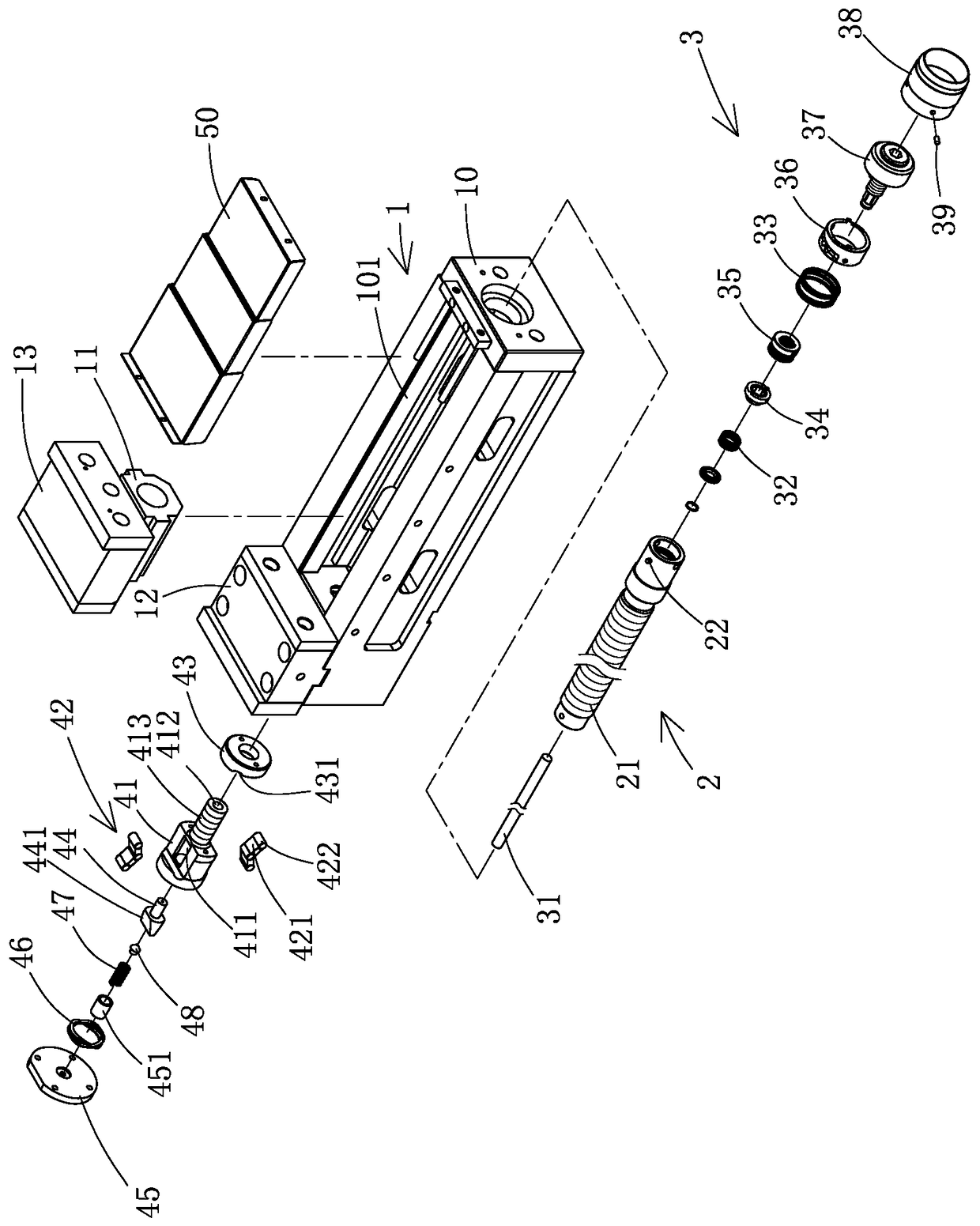

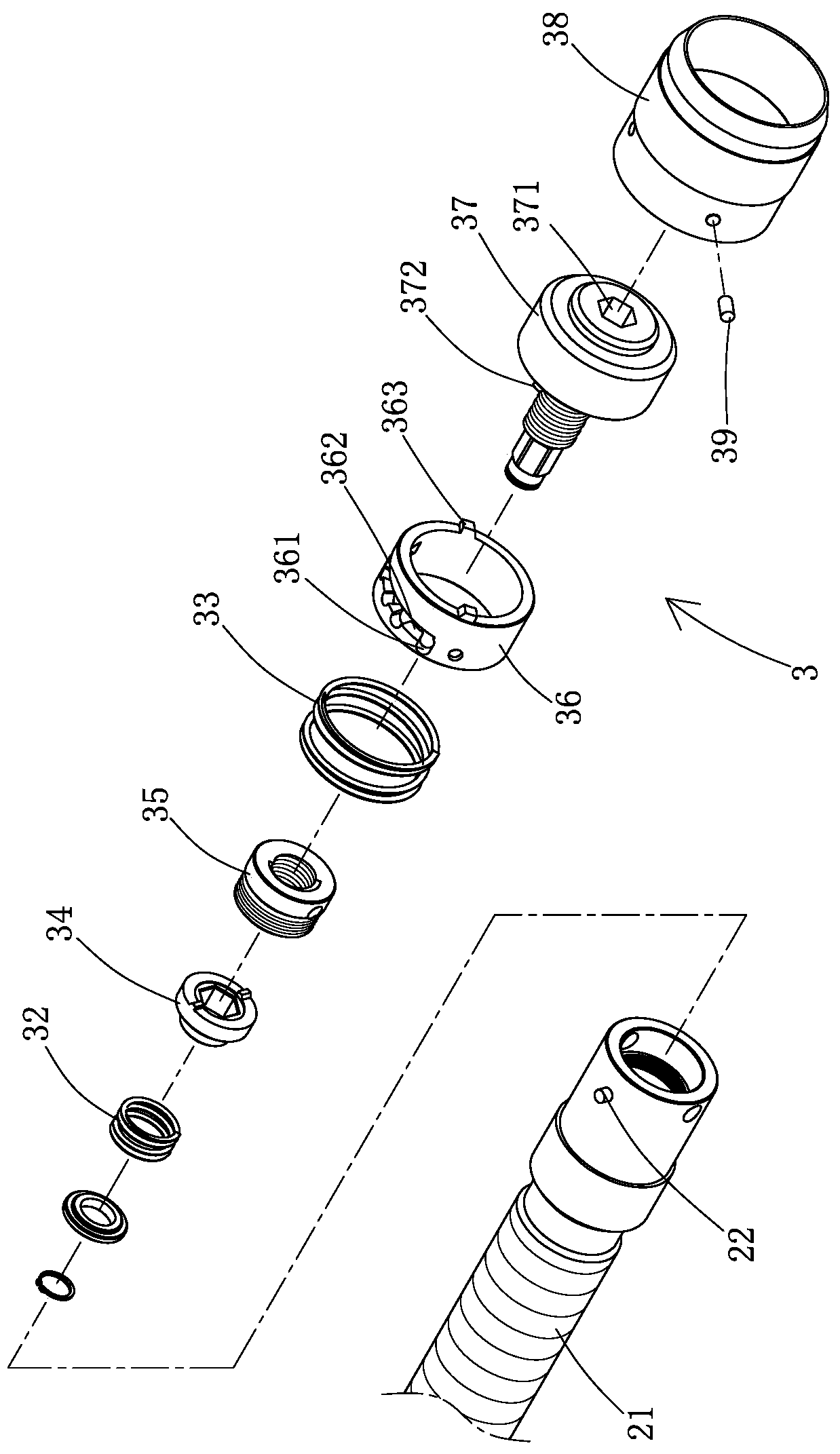

[0050] The following is further described in conjunction with the drawings of the preferred embodiments of the present invention, in order to enable those skilled in the art to implement according to the statements in this specification.

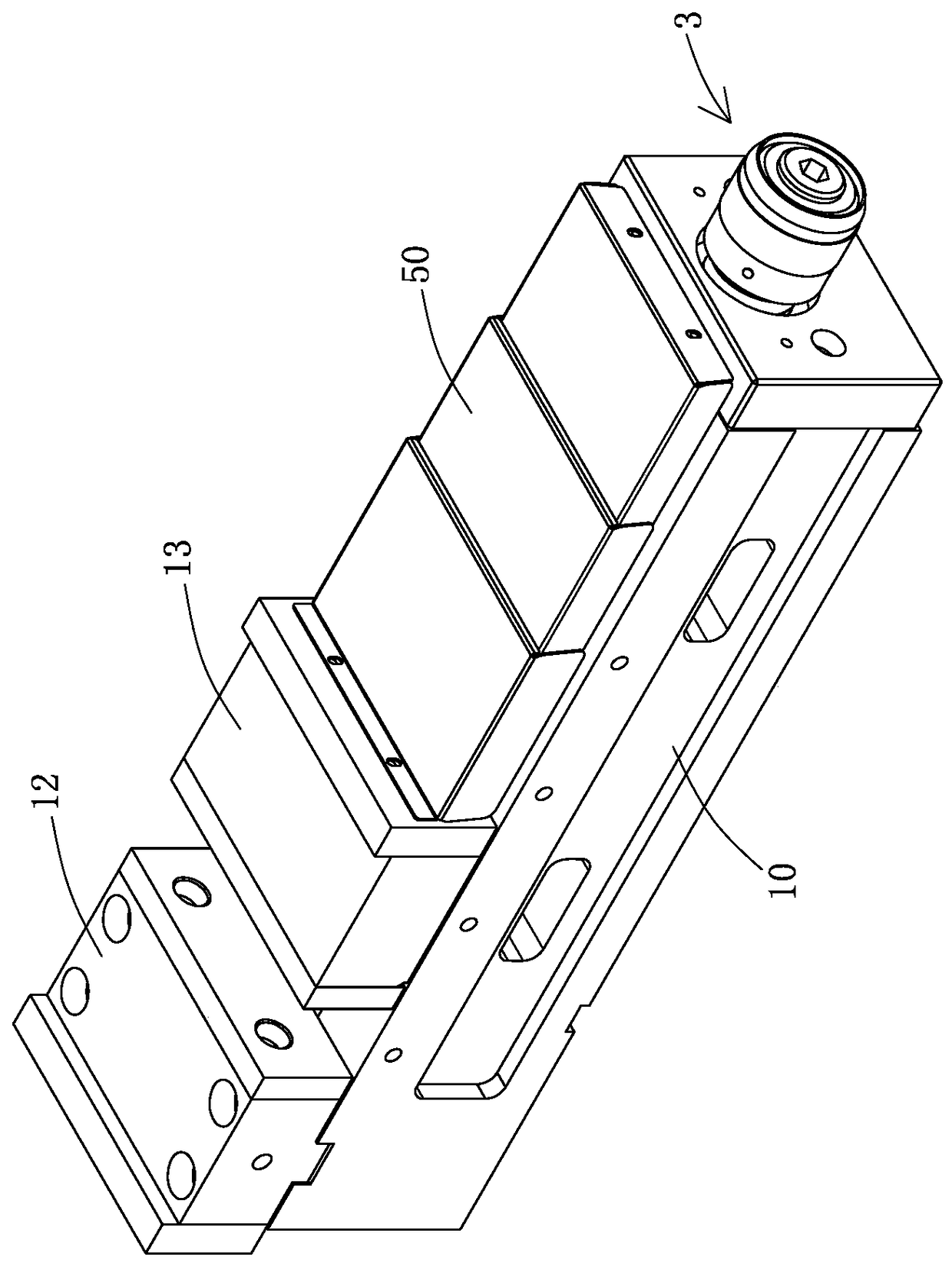

[0051] First, please refer to Figure 1 to Figure 6As shown, the present invention is a pressure regulating structure of double-force type vise, which comprises:

[0052] A vise unit 1, the vise unit 1 has a body 10, a guide rail 101 is provided at the set position on the inner edge of the body 10, and the guide rail 101 is provided for a corner tooth seat 11 with a pressing inclined surface 111 to slide. A fixed jaw 12 is fixed on one side of the top surface of the main body 10, and a movable jaw 13 with a pressure rod 131 is installed on the top surface of the body 10 different from the fixed jaw 12, so that the pressure rod 131 can be moved by the pressure rod 131. The pressing slope 111 is pressed against;

[0053] A transmission unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com