A button-feeding device with a swing arm manipulator controlled by software

A technology of software control and manipulator, which is applied in the direction of storage device, feeding device, positioning device, etc., can solve the problems of poor versatility, reduce the trouble of customization and replacement, and achieve the effect of universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

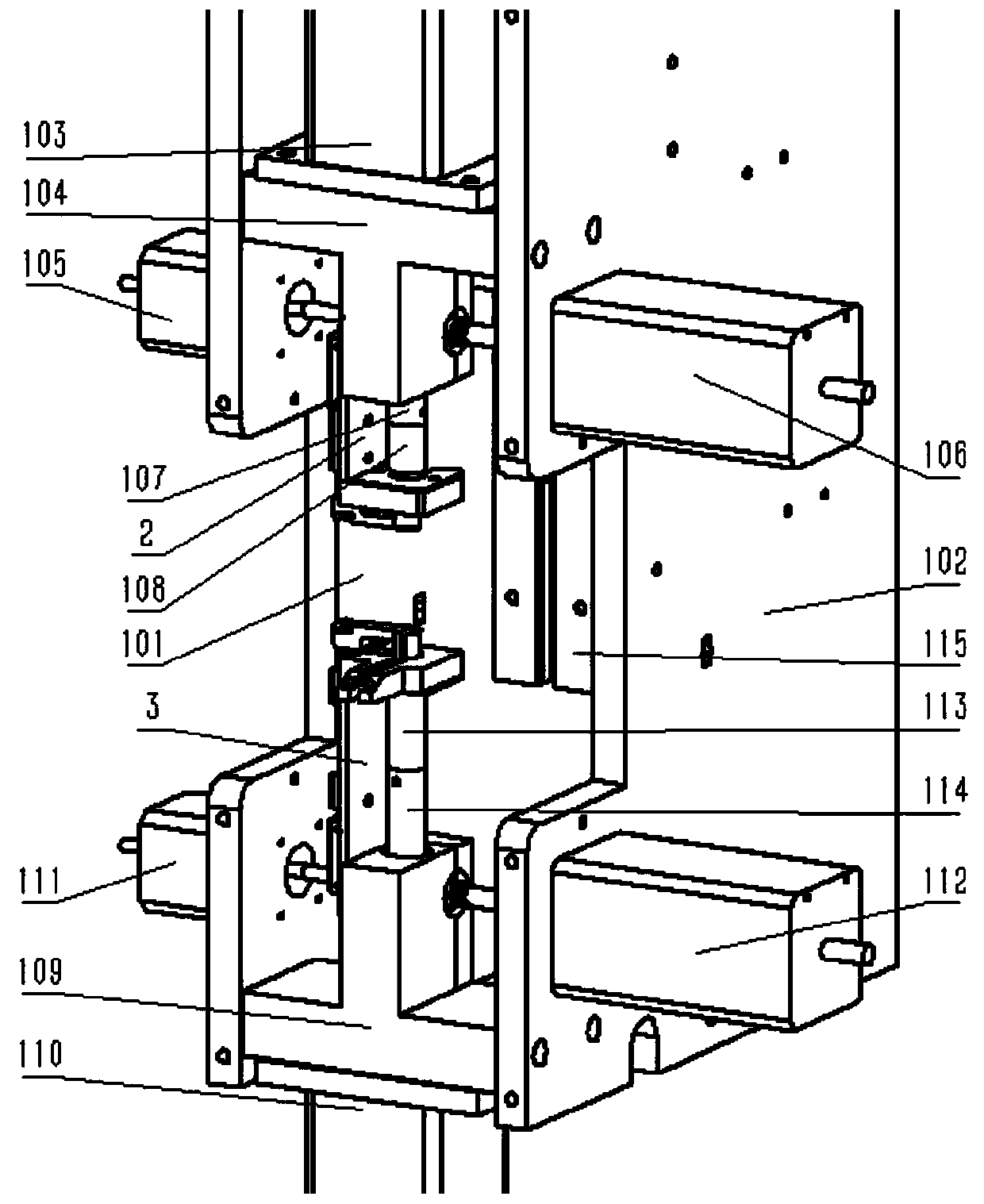

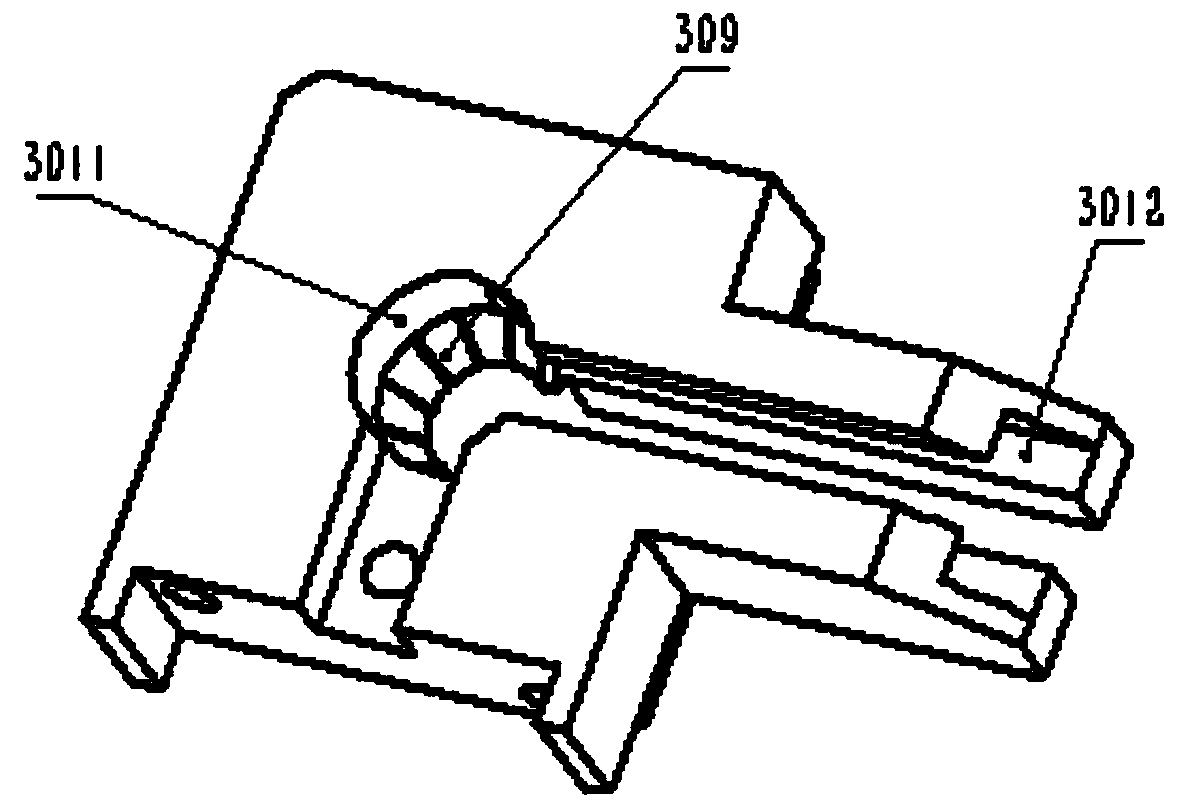

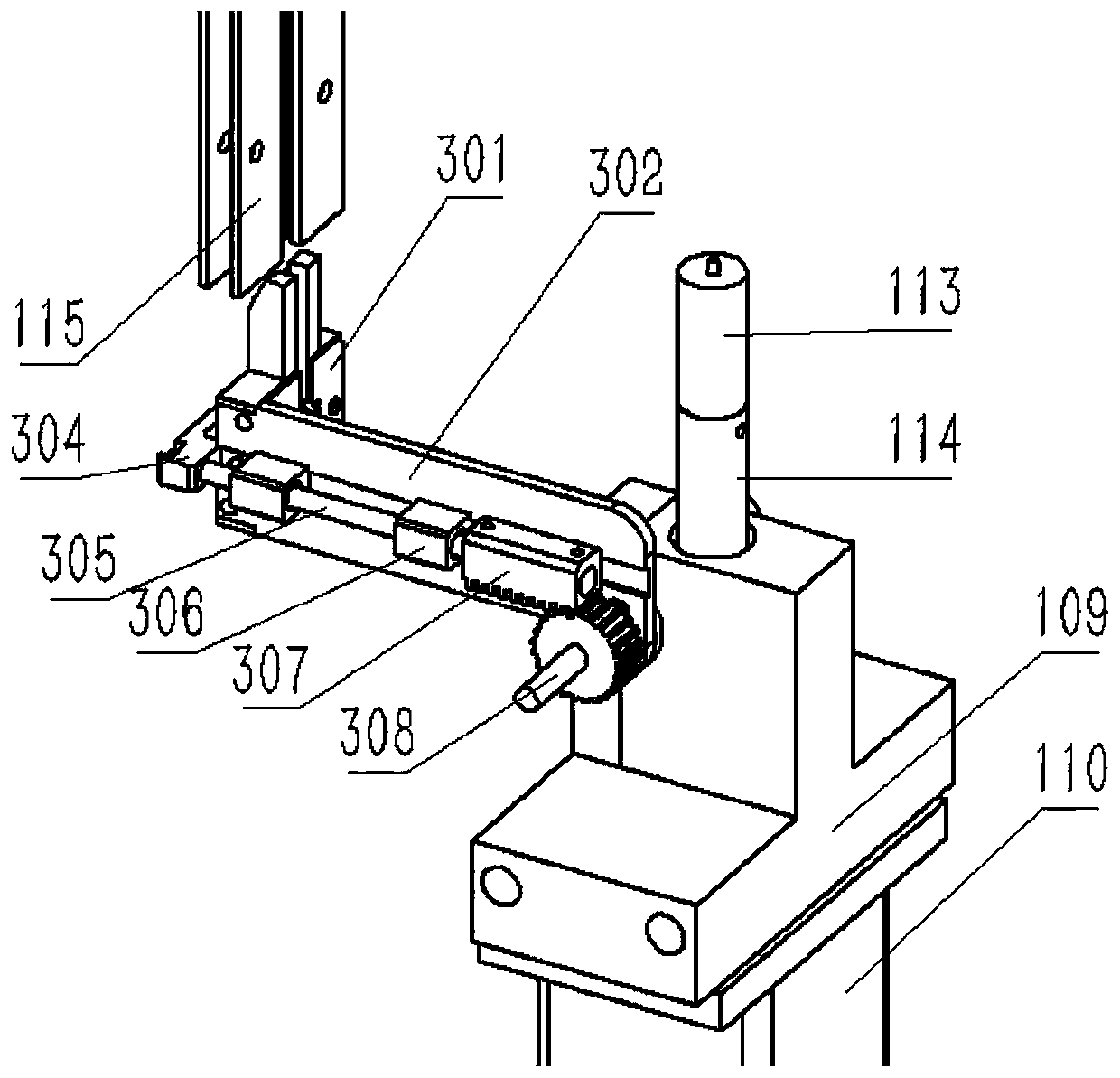

[0019] A button-feeding device with a swing arm manipulator controlled by software, used for button-down, see figure 1 , including a software control device, a left wallboard 101 and a right wallboard 102 opposite to it, a stamping seat 109 is fixed between the left and right wallboards, and a vertical through hole and a transverse through hole are arranged in the stamping seat 109, A bearing is arranged in the horizontal through hole, and a sliding sleeve is housed in the vertical hole. The punch rod 114 vertically passes through the stamping seat 109 through the sliding sleeve. Its swing shaft 303 is installed on the bearing in the transverse through hole of the stamping seat 109, on the left side of the swing arm manipulator 3, the button motor 111 is relatively connected with the gear 308 axis of the swing arm manipulator 3 and fixed on the left wallboard. On the left side, on the right side of the swing arm manipulator 3, the swing arm motor 112 is relatively connected wi...

Embodiment 2

[0024] This device can also adjust the direction and direction of the swing arm, the shape of the swing head, and change the installation direction to apply to dies with different orientations. For example, see figure 1, when installed upside down 180 degrees, the upper swing arm manipulator 2 can be used for buckle-up, and shares a software control with the lower swing arm manipulator 3 to form a buckle feeding system that works up and down simultaneously, including the left wall plate 101 and its opposite setting The right wallboard 102, the upper stamping seat 104 is fixed directly above the stamping seat 109 between the left and right wallboards, the upper stamping seat 104 is provided with a vertical through hole and a horizontal through hole, and the horizontal through hole is provided with Bearing, sliding sleeve is housed in the vertical hole, upper punch 107 passes through upper stamping seat 104 vertically through sliding sleeve, upper die 108 is installed on the lowe...

Embodiment 3

[0029] Design changes the round holes of the upper swing head 201 and the swing head 301 to be square holes, triangular holes, oval holes, polygonal holes and just be applicable to the feeding of more shaped nails, buttons, or similar materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com