Decorative material smashing and mixing device

A technology of mixing device and decorative materials, applied in the field of decorative materials, can solve the problems of complicated process, long processing cycle, low work efficiency, etc., and achieve the effect of reducing processing cycle, improving crushing quality and improving work efficiency

Active Publication Date: 2018-06-26

聊城泽润装饰工程有限公司

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The whole process is complicated and the processing cycle is long, resulting in low work efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

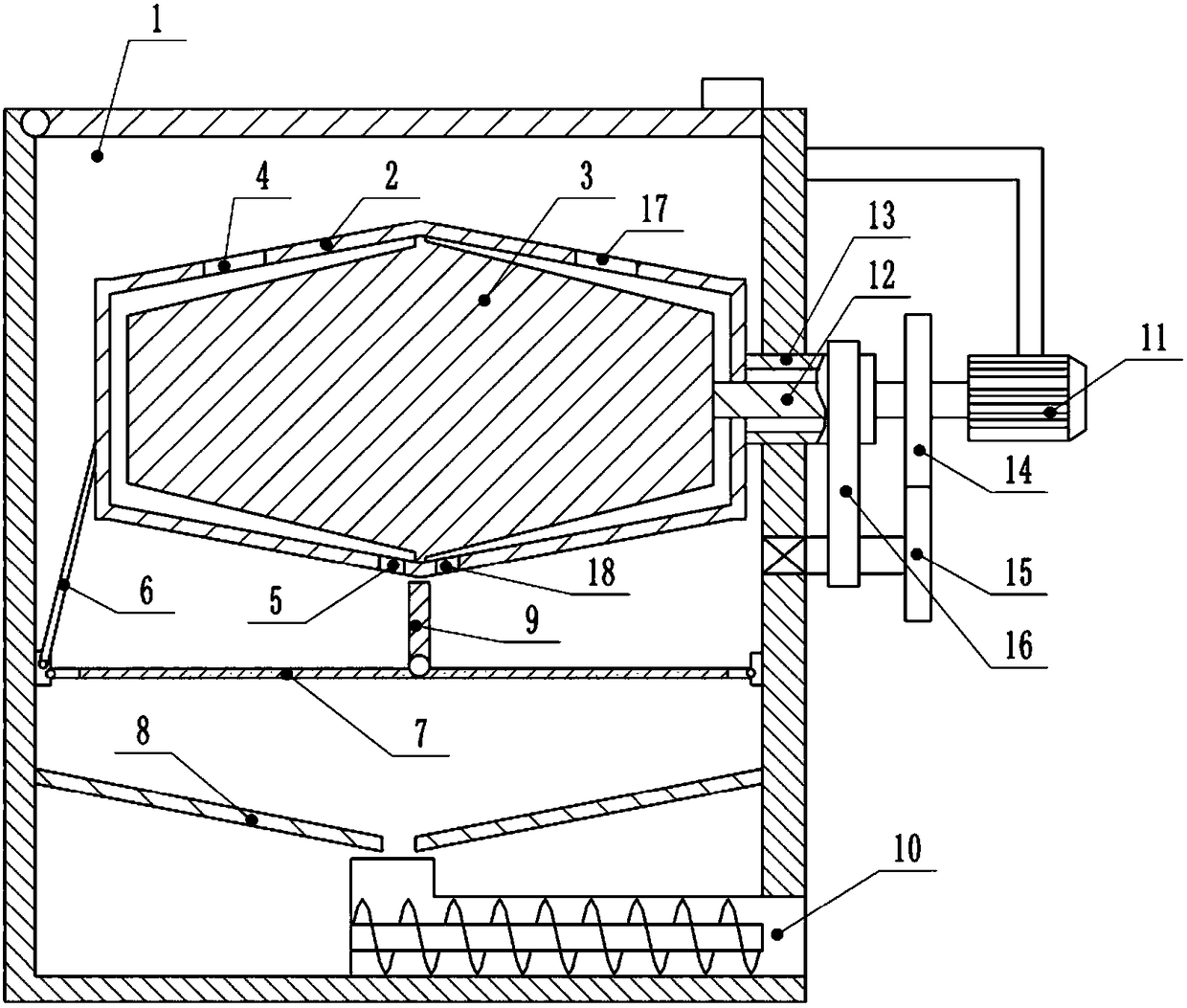

The invention belongs to the technical field of decorative materials and particularly discloses a decorative material smashing and mixing device. The decorative material smashing and mixing device comprises a box. A crushing mechanism is arranged in the box. The crushing mechanism comprises an inner roller and an outer roller. The outer roller comprises a coarse crushing outer roller body and a fine crushing outer roller body. The inner roller comprises a coarse crushing inner roller body and a fine crushing inner roller body. The outer roller is internally provided with a cavity. The coarse crushing inner roller body is shaped like a circular truncated cone and is located in the coarse crushing outer roller body. The conicity of the coarse crushing inner roller body is greater than that of the coarse crushing outer roller body. The fine crushing inner roller body is shaped like a circular truncated cone and is located in the fine crushing outer roller body. The conicity of the fine crushing inner roller body is greater than that of the coarse crushing inner roller body. The sidewall of the fine crushing outer roller body is provided with a first discharge port. The sidewall of thecoarse crushing outer roller body is provided with a second discharge port. A filter screen is arranged below the crushing mechanism. A partition board is arranged on the filter screen. Filter gaps of the filter screen on the two sides of the partition board are different. A material mixing plate is arranged below the filter screen. An outlet is formed in the center of the material mixing plate.Through the scheme, the decorative material smashing and mixing device achieves crushing and mixing of different decorative materials.

Description

technical field [0001] The invention belongs to the technical field of decorative materials, in particular to a crushing and mixing device for decorative materials. Background technique [0002] The decoration materials are divided into two parts: one part is outdoor materials and the other part is indoor materials. Indoor materials are further divided into five types: stone, plate, sheet, profile, and wire. Interior decoration materials refer to covering materials used for interior walls, ceilings, columns, floors, etc. of buildings. Modern interior decoration materials can not only improve the indoor artistic environment and enable people to enjoy beauty, but also have multiple functions such as heat insulation, moisture resistance, fire prevention, sound absorption, and sound insulation, which can protect the main structure of the building and prolong the service life. As well as the function of meeting some special requirements, it is an indispensable material for mode...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B02C15/16B02C15/00B02C23/10B07B1/34B07B1/42

CPCB02C15/004B02C15/006B02C15/16B02C23/10B02C2015/008B07B1/343B07B1/42

Inventor 蒲磊

Owner 聊城泽润装饰工程有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com